A high solid content semi-solid electrode, its preparation method and a lithium slurry flow battery comprising the electrode

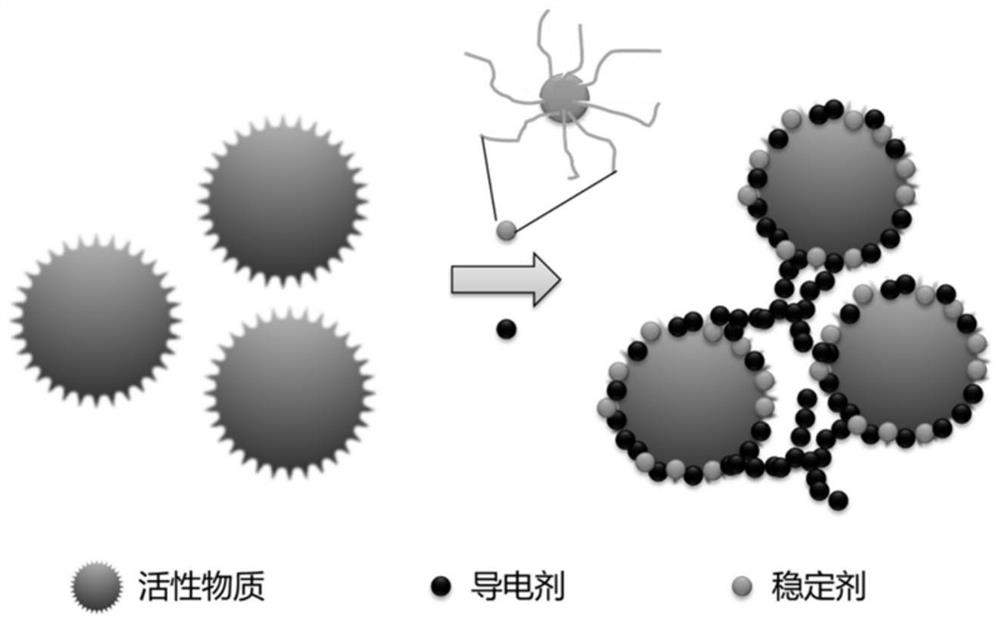

A liquid flow battery, high solid content technology, applied in the direction of lithium battery, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of high battery consistency requirements, complex battery management system, strong V ion toxicity, etc., to reduce Effects of battery side reactions, improving Coulombic efficiency, and stabilizing battery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

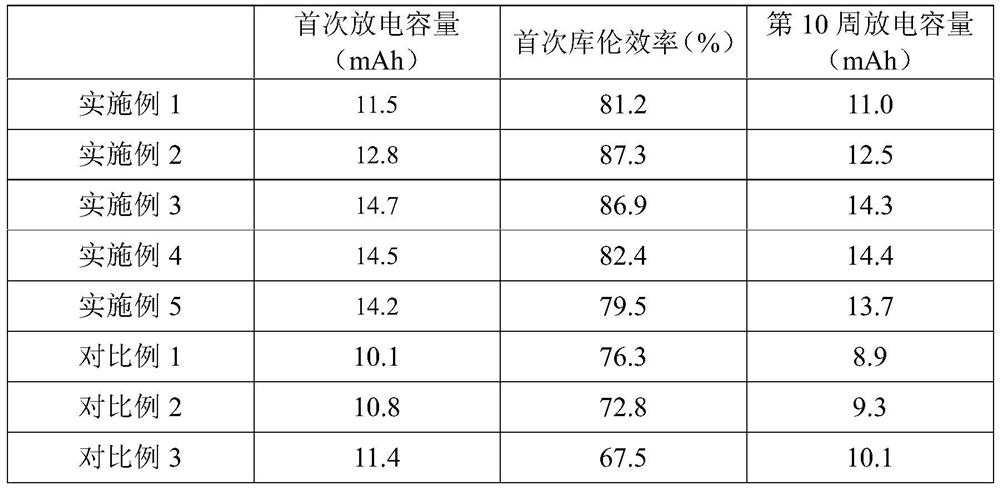

Embodiment 1

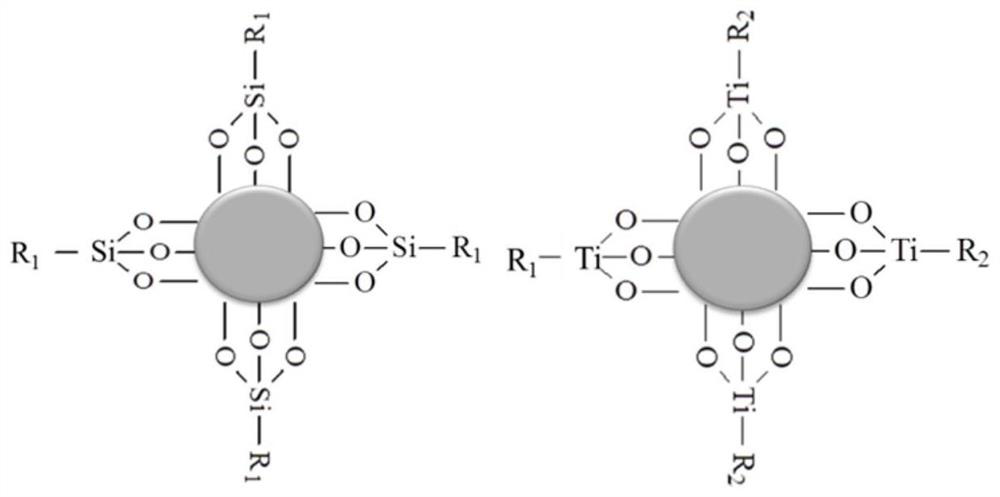

[0033] In an environment with a dew point of -52°C, lithium cobaltate with a D50 of 8 μm is used as the active material, Ketjen black (KB) and carbon nanotubes (CNT) are added as conductive agents, and the dispersant is grafted with butylsilane. SiO with a diameter of 10-15nm 2 Nanoparticles, weigh 60 parts of lithium cobaltate, 3 parts of KB, 5 parts of CNT and 5 parts of dispersant, add to DMC with 15 parts of active material mass, and mechanically stir for 30 minutes to obtain premix 1, the system temperature is the highest during the mixing process At about 63°C, a small amount of DMC in the premix volatilizes.

[0034] The premix was added to a total of 12.37 parts of a mixture of EC:VC:LiDFOB=15.6:1:1, and the mixture was further stirred for 20 minutes to obtain premix 2.

[0035] Freeze the premix to 5°C, add 3.5 parts of LiPF 6 , mixed evenly to obtain a slurry.

[0036] The slurry is coated on the nickel foam to obtain a semi-solid electrode.

[0037]Freeze the el...

Embodiment 2

[0039] The active material uses 70 parts (mass ratio, the same below) of lithium iron phosphate with a D50 of 150nm. In an environment with a dew point of -50°C, 2 parts of conductive carbon black Super P and 3 parts of carbon nanotubes are added as conductive agents and dispersants. 5 parts of TiO with a diameter of 5-15 nm grafted with fluoro-n-butylsilane 2 For nanoparticles, the four components were mixed in proportion and then mechanically mixed in a dry mixer for 60 minutes to obtain premix 1. During the mixing process, the system temperature was at a maximum of about 78°C.

[0040] Add 5.8 parts of EC, 10.8 parts of DMC, 0.37 parts of VC and 0.37 parts of LiFSI to premix 1, and mechanically stir in a mixing tank with a cooling device for 100 minutes to obtain premix 2. The maximum temperature during the mixing process is about 53°C.

[0041] Freeze the premix to 5°C, add 2.6 parts of LiPF 6 , mixed evenly to obtain a slurry.

[0042] The slurry is coated on the surfa...

Embodiment 3

[0045] The implementation process is the same as in Example 2, but the active material is NCM622 large single crystal with a D50 of 3 μm, and the ambient humidity is controlled at a dew point of -55°C. The mass of active material in a single sheet is about 85 mg, and the N / P ratio of the battery is about 1.57. The battery test voltage range is 2.8 ~ 4.4V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com