Knife, fork and spoon formed by food raw materials and preparation process thereof

A preparation process and a technology for forming knives, which are applied in the field of food raw materials forming cutlery, fork, spoon and preparation process thereof, can solve the problems of load-bearing capacity, poor water resistance, low nutritional value and health care effect, and plastic cutlery, fork and spoon are difficult to degrade, and the like. The effect of reducing water absorption, solving the excessive absorption of calories and sugar, and being safe to eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

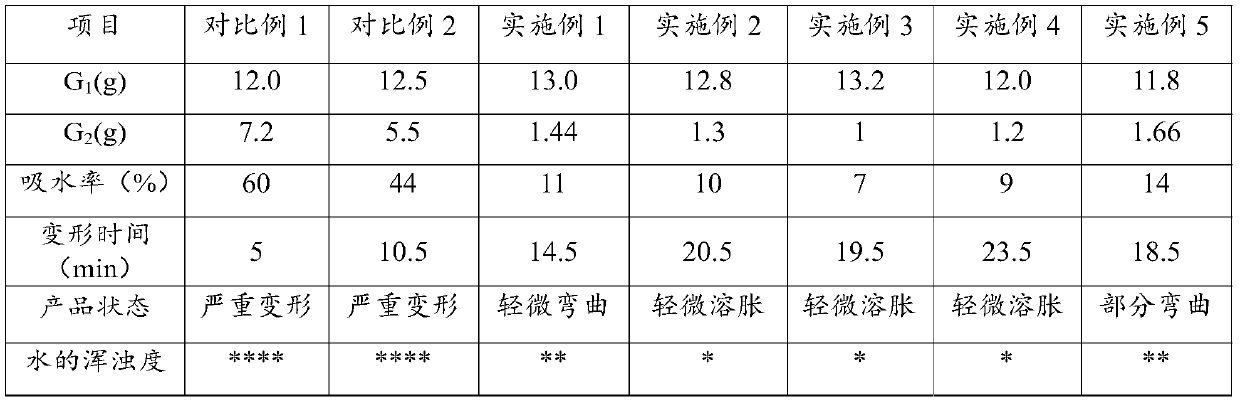

Embodiment 1

[0057] A food raw material forming table spoon provided in this embodiment is prepared according to the following steps:

[0058] S1, preparation of protein nutrient solution: 2 parts of soybean protein isolate powder and 2 parts of whey protein powder were uniformly mixed and dispersed in water to obtain a solution; wherein the total concentration of the soybean protein isolate powder and the whey protein powder was 10wt %; add 1wt% gelatin to the solution and mix evenly, adjust the pH to 7 to obtain protein nutrition solution.

[0059] S2, ingredients: 30 parts of wheat flour, 10 parts of cheese, 10 parts of tapioca starch, 10 parts of lard, 10 parts of eggs, 4 parts of milk powder, 4 parts of white kidney bean extract, 0.5 parts of Moringa leaf, 2 parts of green tea powder.

[0060] Add water and steam the above-mentioned raw materials to obtain a gelatinized product, add protein nutrient solution to the gelatinized product, and beat it into a slurry at a stirring speed of ...

Embodiment 2

[0064] A kind of food raw material molded dinner fork provided in this embodiment is prepared according to the following steps:

[0065] S1, preparation of protein nutrient solution: 2 parts of soybean protein isolate powder and 2 parts of whey protein powder were uniformly mixed and dispersed in water to obtain a solution; wherein the total concentration of the soybean protein isolate powder and the whey protein powder was 10wt %; add 1wt% gelatin to the solution and mix evenly, adjust the pH to 7 to obtain protein nutrition solution.

[0066] S2, ingredients: 30 parts of wheat flour, 10 parts of cheese, 10 parts of tapioca starch, 15 parts of lard, 10 parts of eggs, 4 parts of milk powder, 2 parts of L-arabinose, 0.5 parts of Moringa leaf, 2 parts of purple sweet potato powder.

[0067] Add water and steam the above-mentioned raw materials to obtain a gelatinized product, add protein nutrient solution to the gelatinized product, and beat it into a slurry at a stirring speed ...

Embodiment 3

[0071] A kind of food raw material forming table knife provided in this embodiment is made according to the following steps:

[0072] S1, preparing protein nutrient solution: mix 2 parts of soybean protein isolate powder and 2 parts of bovine osseoprotein peptide powder evenly and disperse them in water to obtain a solution; wherein the total concentration of the soybean protein isolate powder and the whey protein powder is 10wt%; 4wt% gelatin was added to the solution and mixed evenly, and the pH was adjusted to 7 to obtain a protein nutrient solution.

[0073] S2, ingredients: 30 parts of wheat flour, 10 parts of cheese, 10 parts of tapioca starch, 10 parts of lard, 10 parts of eggs, 4 parts of milk powder, 4 parts of white kidney bean extract, 1 part of edible algae, 2 parts of green tea powder.

[0074] Add water and steam the above-mentioned raw materials to obtain a gelatinized product, add protein nutrient solution to the gelatinized product, and beat it into a slurry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com