Waste rubber material-based electrode material for secondary battery and preparation method of electrode material

A waste rubber, secondary battery technology, applied in battery electrodes, secondary batteries, negative electrodes, etc., can solve problems such as poor battery cycle performance and rate performance, high electrochemical impedance of porous carbon materials, human skin and respiratory tract damage. , to achieve the effect of high capacity, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

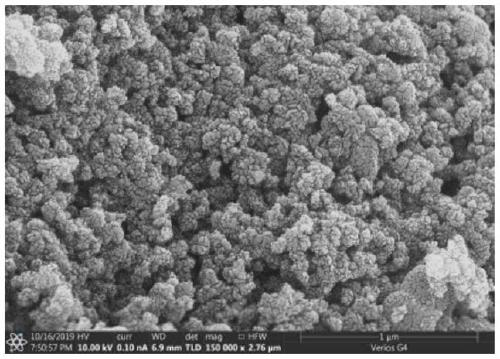

[0082] 1. Preparation of secondary carbon-sulfur particle NCS matrix

[0083] Use a pulverizer to grind the cleaned waste rubber into waste rubber powder with a particle size of 2-3 μm, weigh 1000g of waste rubber powder and 50g of impurity remover potassium fluoride and mix them evenly in solid phase, then place them in a high-temperature atmosphere furnace, nitrogen flow rate Heat up to 500°C for 4 hours at a heating rate of 2°C / min, cool naturally to room temperature, crush through a 200-mesh sieve, wash with ethanol solution to remove ungasified fluoride, and dry to remove Secondary carbon-sulfur particle NCS matrix after impurities.

[0084] 2. The substrate is coated with pyrolytic carbon coating layer C

[0085] Solid-phase coating granulation is adopted. According to the mass ratio of 100:6, NCS and coating agent powder pitch are mixed evenly in solid phase and then transferred to a ball mill tank. The grinding body is zirconia balls with a particle size of 3 mm. NCS ...

Embodiment 2

[0089] 1. Preparation of secondary carbon-sulfur particle NCS matrix

[0090] Use a pulverizer to crush the cleaned waste rubber into waste rubber powder with a particle size of 2-3 μm, weigh 1000g of waste rubber powder and 80g of impurity remover potassium bromide in solid phase and mix them evenly in a high-temperature atmosphere furnace. The flow rate is 6L / min, and the temperature is raised to 700°C at a heating rate of 2.5°C / min for 3.5 hours, and then cooled to room temperature naturally. After being crushed through a 200-mesh sieve, it is washed with ethanol solution to remove ungasified bromide. After drying, The secondary carbon-sulfur particle NCS matrix after removing impurities is obtained.

[0091] 2. The substrate is coated with pyrolytic carbon coating layer C

[0092] Using liquid phase coating, according to the mass ratio of 100:7, NCS and coating agent sucrose are added to the ethanol solution, the mass of NCS and coating agent is 28% of the sum of the mass...

Embodiment 3

[0104] 1. Preparation of secondary carbon-sulfur particle NCS matrix

[0105] Use a pulverizer to crush the cleaned waste rubber into waste rubber powder with a particle size of 2 to 3 μm, weigh 1000g of waste rubber powder and 100g of impurity remover sodium fluoride and mix them evenly in solid phase, then place them in a high-temperature atmosphere furnace, helium gas The flow rate is 7L / min, heat up to 800°C at a heating rate of 3°C / min for 3 hours, cool naturally to room temperature, grind through a 200-mesh sieve, wash with methanol solution to remove ungasified fluoride, and dry to obtain Secondary carbon-sulfur particle NCS matrix after removing impurities.

[0106] 2. The substrate is coated with pyrolytic carbon coating layer C

[0107] Solid-phase coating granulation is adopted. According to the mass ratio of 100:8, NCS and coating agent emulsified asphalt are mixed evenly in solid phase and then transferred to a mechanical fusion machine. Mixing and coating at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com