Dichloroethylene-acrylate copolymer emulsion and preparation method thereof

A vinylidene chloride and acrylate technology, applied in the field of emulsion preparation and metal anticorrosion, can solve the problems of poor salt spray resistance, single application of coatings, poor heat resistance, etc., to improve adhesion, reduce formaldehyde content, and improve comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

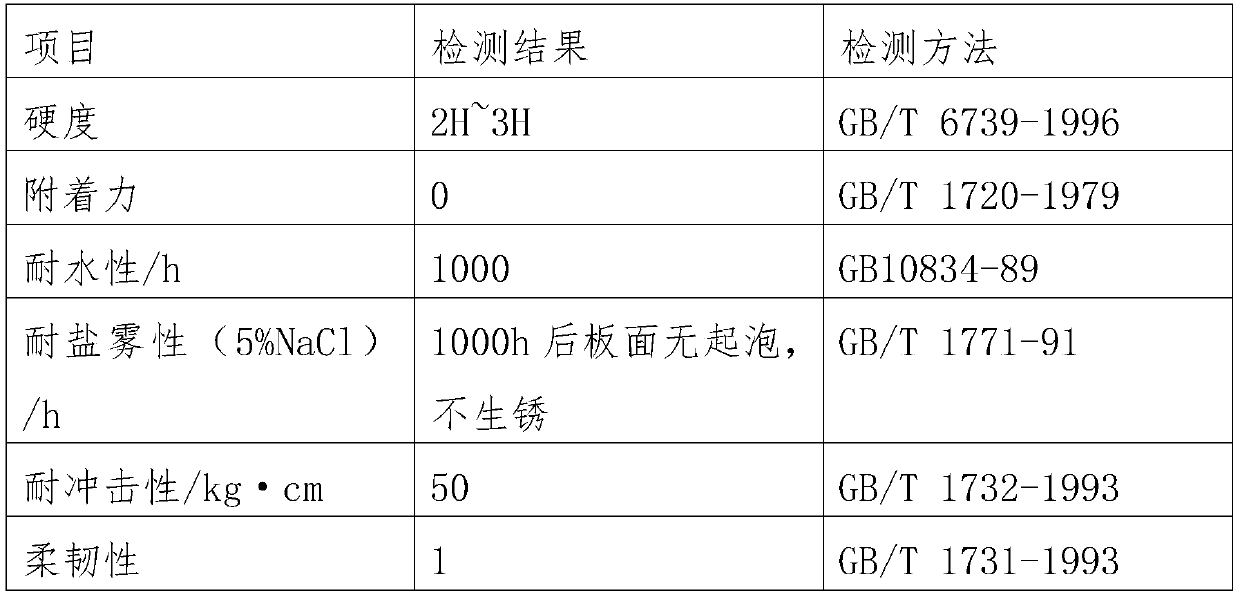

Examples

preparation example Construction

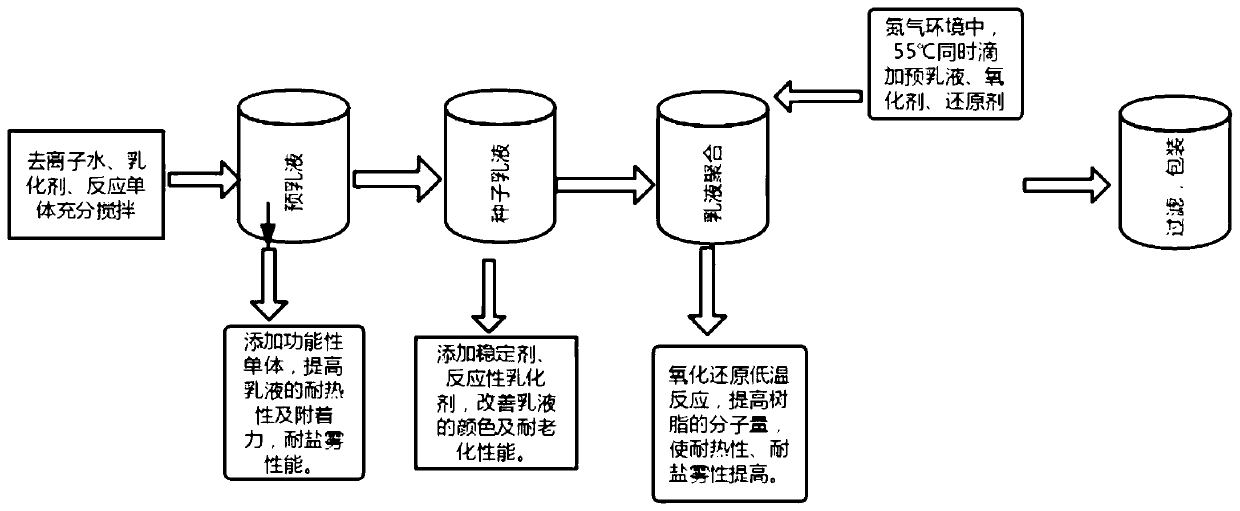

[0074] The preparation method of ethylene dichloride-acrylic acid ester copolymerization emulsion, comprises the steps:

[0075] Step 1. Preparation of pre-emulsion: Stir reactive anionic emulsifier, nonionic emulsifier, dichloroethylene, A-type reactive monomer, B-type reactive monomer, C-type reactive monomer, and deionized water at room temperature at high speed 0.5 hour, prepare pre-emulsion;

[0076] Step 2. Preparation of seed emulsion: In a reactor, stir, dissolve and mix deionized water and reaction stabilizer, pass nitrogen through the dissolved mixture to remove oxygen, then heat up the mixed liquid to 55°C, add value in the pre-emulsion prepared in step 1 of 5-10%, to obtain the seed emulsion; then add 30% oxidizing agent solution, 30% reducing agent solution and all accelerators in sequence;

[0077] Step 3, emulsion dropwise polymerization: After the seed emulsion reaction system obtained in step 2 turns blue, add the remaining pre-emulsion and the remaining redo...

Embodiment 1

[0081] The preparation method of ethylene dichloride-acrylic acid ester copolymerization emulsion, comprises the steps:

[0082] Dissolve 0.5g of α-allyl alkylphenol polyoxyethylene ether ammonium sulfate and 1.0g of isomeric C12-C13 alcohol polyoxyethylene ether in 45g of deionized water, and add 1.0g of 2-acrylamide under the condition that the system temperature is <30°C -2-Methylpropanesulfonic acid, 2.0g methacrylic acid, 7.3g methyl methacrylate, 13.3g isooctyl acrylate, 76.4g 1,1-dichloroethylene, emulsified with high-speed stirring to obtain a pre-emulsion;

[0083] Add 40g of deionized water and 0.005g of EDTA into the reactor, vacuumize, and fill with nitrogen three times, take 7.25g of the pre-emulsion and pump it into the reactor, raise the temperature to 50°C, add 0.0003g of ferrous sulfate heptahydrate, 0.03 g tert-butyl hydroperoxide, 0.03g ascorbic acid reducing agent, react for 15-30min, and the reaction temperature rises to 55°C;

[0084] After the seeds hav...

Embodiment 2

[0099] The preparation method of ethylene dichloride-acrylic acid ester copolymerization emulsion, comprises the following steps:

[0100] Dissolve 0.5g of long-chain alkyl alcohol polyoxyethylene ether methacrylate and 1.0g of isomeric C12-C13 alcohol polyoxyethylene ether in 45g of deionized water, and add 1.0g of 2-acrylamide when the system temperature is <30°C - 2-methylpropanesulfonic acid, 2.0g methacrylic acid, 13.3g methyl methacrylate, 13.7g isooctyl acrylate, 70g 1,1-dichloroethylene, emulsified with high-speed stirring to obtain a pre-emulsion.

[0101] Add 40g of deionized water and 0.005g of EDTA into the reactor, vacuumize, and fill with nitrogen three times, take 7.25g of the pre-emulsion and pump it into the reactor, raise the temperature to 50°C, add 0.0003g of ferrous sulfate heptahydrate, 0.03 g tert-butyl hydroperoxide, 0.03 g ascorbic acid reducing agent, react for 15-30 min, and the reaction temperature rises to 55°C.

[0102] After the seeds have been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com