Supported hollow sphere carbon material and preparation method thereof and application in electrocatalysis

A hollow sphere, load-carrying technology, applied in the direction of circuits, electrical components, battery electrodes, etc., to achieve high specific surface area, excellent mass transfer performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of hollow spherical carbon carrier

[0036] Add 0.5 mL of tetraethyl orthosilicate to the mixed solution containing 10 mL of ethanol and 30 mL of 1M KOH, then add 100 mg of L-dopamine, stir at 500 rpm for 6 h, centrifuge at 10000 rpm for 5 min and wash with water three times, 80 ℃ drying for 12h, at a gas flow rate of 60mLmin -1 and a heating rate of 2°C min -1 Under an argon atmosphere at 800°C for 2 hours; then wash with 200mL, 1.5M NaOH at 60°C for 12 hours to remove the template, and wash to neutral to obtain a hollow spherical carbon carrier;

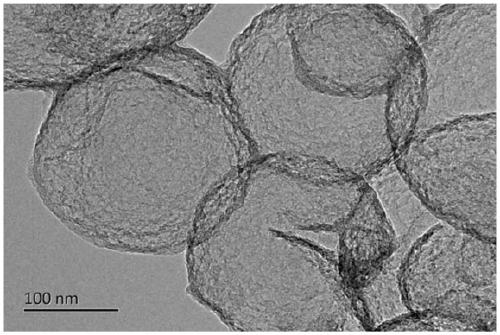

[0037] Such as figure 1 , the transmission electron microscope picture of the hollow spherical carbon carrier prepared in Example 1, the electron microscope shows that the particle size of the carbon carrier is uniform, and the size distribution range is 200-300nm;

[0038] (2) Preparation of supported catalyst

[0039] Dissolve 15 mg of hemin in 150 mL of dichloromethane solvent, add 150 mg of the hollow...

Embodiment 2

[0043] (1) Preparation of hollow spherical carbon carrier

[0044] Add 0.5mL of methyl orthosilicate to the mixture containing 20mL of ethanol and 40mL of 2M KOH, then add 250mg of dihydroxyphenylpropyl methacrylamide, stir for 6h at a stirring rate of 600rpm, and centrifuge at a rate of 10000rpm Centrifuge for 5min and wash with water three times, dry at 80°C for 12h, at a gas flow rate of 60mLmin -1 and a heating rate of 2°C min -1 800°C constant temperature for 2 hours under the ammonia atmosphere; and then washed with 200mL, 2M NaOH at 40°C for 12 hours to remove the template, and then washed to neutral to obtain the hollow spherical carbon carrier;

[0045] (2) Preparation of supported catalyst

[0046] Dissolve 20 mg of vitamin B12 in 150 mL of ethanol, add 150 mg of the hollow spherical carbon carrier prepared in (1), ultrasonicate for 30 min, and spin evaporate at room temperature. -1 and a heating rate of 10°C min -1 In a helium atmosphere, keep the temperature at...

Embodiment 3

[0048] (1) Preparation of hollow spherical carbon carrier

[0049] After adding 1.5 mL of tetraethyl orthosilicate to a mixture containing 12 mL of ethanol and 12 mL of 2M ammonia water, add 200 mg of L-dopamine, stir at 600 rpm for 12 h, centrifuge at 13000 rpm for 3 min, and wash with water three times. Dry at 80°C for 12h, at a gas flow rate of 80mLmin -1 and a heating rate of 5°C min -1 Under a nitrogen atmosphere at 1000°C for 0.5h; then wash with 200mL, 1.5M KOH at 30°C for 24h to remove the template and wash to neutral to obtain a hollow spherical carbon carrier;

[0050] (2) Preparation of supported catalyst

[0051] Dissolve 70 mg of iron phthalocyanine in 150 mL of dichloromethane solvent, add 200 mg of the hollow spherical carbon carrier prepared in (1) and carry out ultrasonication for 50 min. -1 and a heating rate of 5°C min -1 In an ammonia atmosphere at 900°C for 2 hours, then pickled with 200 mL of 1M HCl at 80°C for 3 hours to remove impurities, and washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com