Grinding pad and preparation method and application thereof

A technology of grinding pad and grinding layer, which is applied in the field of grinding pads, can solve the problems of high cost of grinding process, cumbersome cleaning process, poor process control ability, etc., achieve green environmental protection, high precision, high process controllability, and good self-repair effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

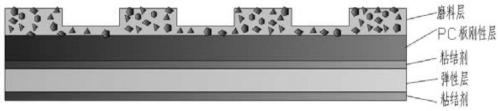

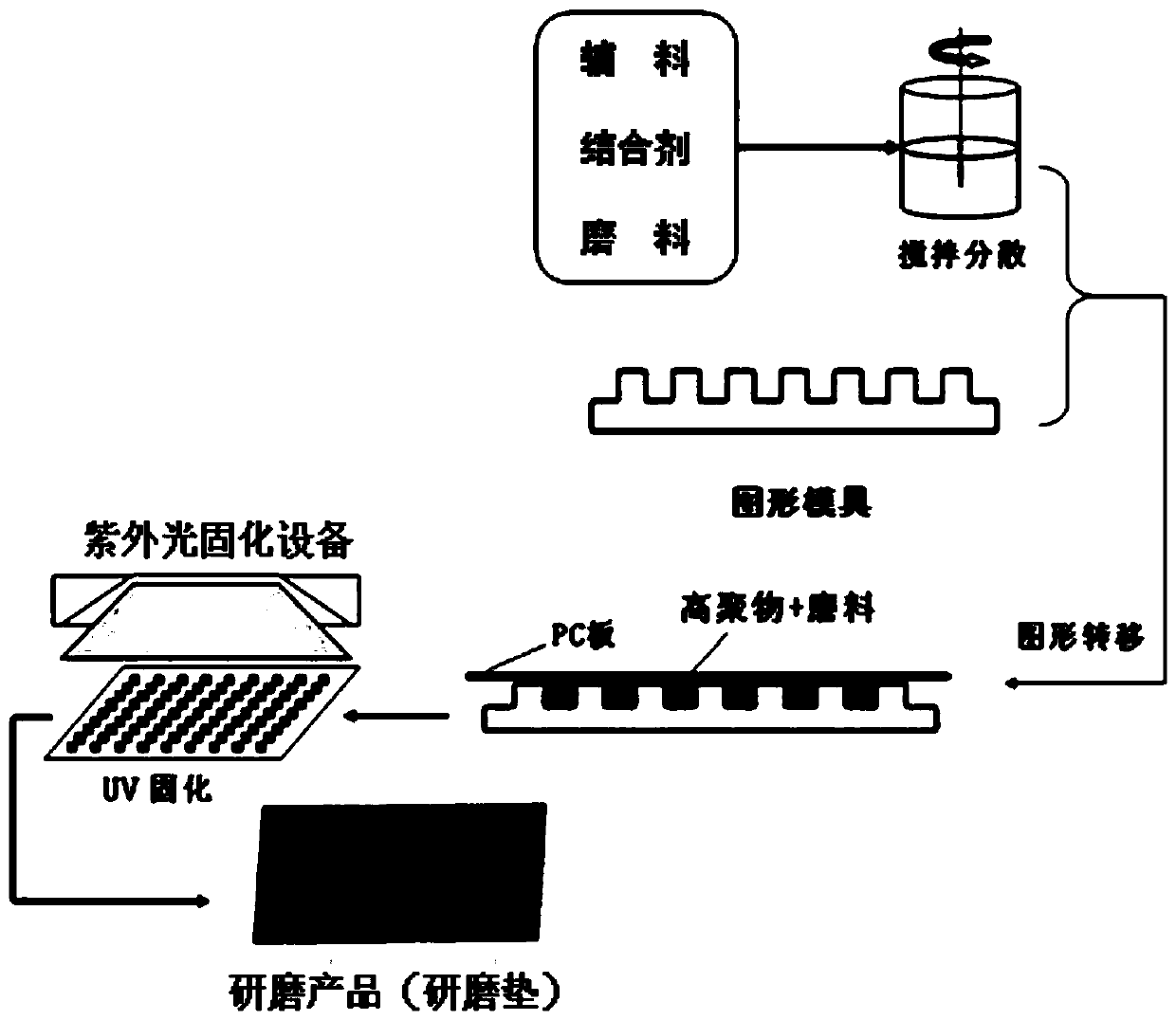

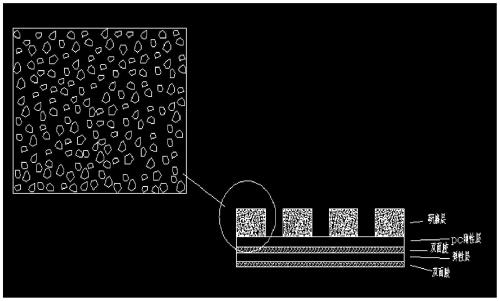

[0031] Example 1 Preparation of the polishing pad of the present invention

[0032] Preparation of raw materials: diamond abrasive raw materials: 80%, binder raw materials: 15%, and other auxiliary materials: 5%. Substrate types: one transparent rigid substrate, one elastic substrate; two double-sided adhesives.

[0033] The diameter of the diamond abrasive is 10um; the auxiliary materials include: sodium chloride particles, graphite powder and coupling agent (3:2:1); the bonding agent is uv curing resin and its initiator (98:2).

[0034] Uv curing resin is acrylated epoxy resin;

[0035] The initiator is cumene hydroperoxide;

[0036] The coupling agent is y-propyltrimethoxysilane;

[0037] The specific preparation method is as follows:

[0038] Prepare the binding agent: put the weighed binding agent into the container, keep the container at 35°C and stir with a stir bar to fully disperse the binding agent, open the air for 20 minutes, and discharge the odor generated when the uv resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com