Preparation technology of anti-static and flame-retardant non-woven fabric

A flame-retardant non-woven fabric and preparation technology, which is applied in the manufacture of fire-resistant and flame-retardant filaments, conductive/antistatic filaments, and non-woven fabrics. It can solve the problems of lack of flame-retardant properties, complex production equipment, and production costs. Advanced problems, to achieve excellent flame retardant effect, long-lasting antistatic performance and flame retardant performance, not easy to fall off and lose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

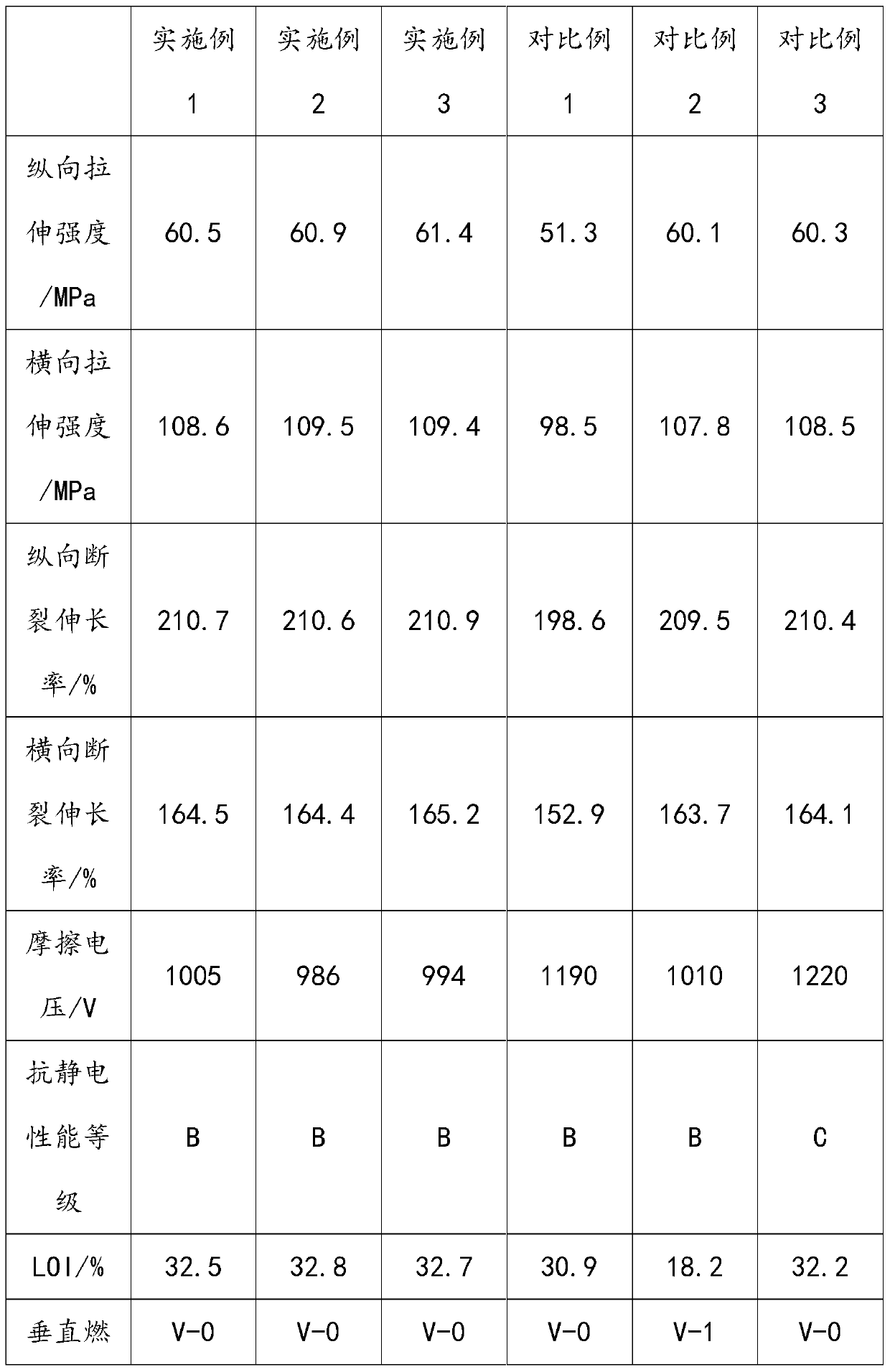

[0027] A preparation process of antistatic flame retardant nonwoven fabric, the nonwoven fabric is PP nonwoven fabric, made of the following raw materials in parts by weight: 80-100 parts of polypropylene, 12-15 parts of maleic anhydride grafted polypropylene, 6-9 parts of reinforcing filler, 1-1.2 parts of flame retardant;

[0028] Reinforcing fillers are prepared by the following methods:

[0029] (1) Dissolving graphene oxide in an airtight container with xylene solution for 24 hours, and drying in an electric thermostat oven at 75°C to obtain pretreated graphene oxide;

[0030] (2) Dissolving dodecyl phosphate in 75% ethanol aqueous solution by volume fraction is prepared as a 10% modified solution by mass fraction;

[0031] (3) Add the pretreated graphene oxide to the modified solution according to the solid-to-liquid ratio of 1g: 20mL, first ultrasonic at room temperature for 10-12min, then raise the temperature to 60°C and stir for 180-200min, filter and dry to obtain ...

Embodiment 1

[0044] A preparation process of antistatic and flame retardant nonwoven fabric, which is made of the following raw materials in parts by weight: 80 parts of polypropylene, 12 parts of maleic anhydride grafted polypropylene, 6 parts of reinforcing filler, and 1 part of flame retardant ;

[0045] The non-woven fabric is made by the following steps:

[0046] The first step is to vacuum-dry all the raw materials with a good ratio at 80°C overnight, and place them in a mixer for mixing to obtain a mixture;

[0047] The second step is to put the mixture into an 80°C electric blast drying oven to dry for 3 hours, put it in a melt-blown spinning machine, raise the screw temperature to 180°C, and control the temperature for 25 minutes. After the temperature is stable, install the spinneret and control the temperature. The temperature of the screw and the die is 180°C, and it is spun into a polypropylene non-woven fabric;

[0048] The third step is to prepare a solution of 1,4-butened...

Embodiment 2

[0050] A preparation process of antistatic and flame retardant nonwoven fabric, which is made of the following raw materials in parts by weight: 90 parts of polypropylene, 14 parts of maleic anhydride grafted polypropylene, 7 parts of reinforcing filler, and 1.1 parts of flame retardant ;

[0051] The non-woven fabric is made by the following steps:

[0052] The first step is to vacuum-dry all the raw materials with a good ratio at 80°C overnight, and place them in a mixer for mixing to obtain a mixture;

[0053] The second step is to dry the mixture in an 80°C electric blast drying oven for 3.5 hours, place it in a melt-blown spinning machine, raise the screw temperature to 180°C, and control the temperature for 28 minutes. After the temperature is stable, install the spinneret. Control the temperature of the screw and the die head at 200°C, and spin it into polypropylene non-woven fabric;

[0054] The third step is to prepare a solution of 1,4-butenediol, benzophenone and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com