Anti-ultraviolet and anti-fog polyethylene greenhouse film and preparation method thereof

An anti-ultraviolet and polyethylene technology, applied in the field of materials, can solve the problems of not being able to prevent fog, and achieve the effects of inhibiting agglomeration, promoting refinement, and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

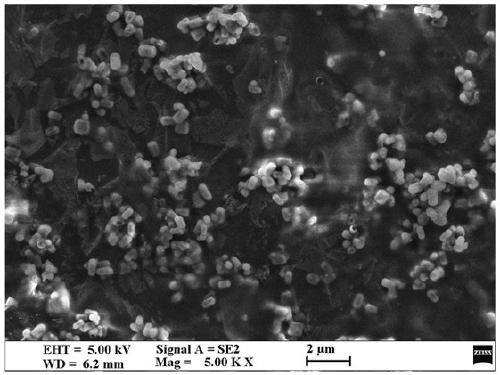

Image

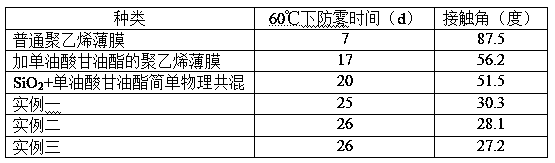

Examples

Embodiment 1

[0031] An anti-ultraviolet and anti-fog polyethylene shed film, comprising the following components in parts by weight:

[0032] LLDPE resin: 100 parts;

[0033] LDPE resin: 30 parts;

[0034] EVA plastic: 30 parts;

[0035] Anti-ultraviolet anti-fog agent rGO / SiO 2 -g-PGMO: 5 parts;

[0036] The LLDPE resin is linear low density polyethylene, and LLDPE is usually produced by copolymerization of ethylene and higher alpha olefins such as butene, hexene or octene at lower temperature and pressure. The LLDPE polymer produced by the copolymerization process has a narrower molecular weight distribution than ordinary LDPE, and has a linear structure that makes it have different rheological properties. The melt flow characteristics of LLDPE adapt to the requirements of the new process, especially the film extrusion process, which can produce high-quality LLDPE products.

[0037] The LDPE resin is low-density polyethylene, and low-density polyethylene usually uses ethylene as a m...

Embodiment 2

[0046] An anti-ultraviolet and anti-fog polyethylene shed film, comprising the following components in parts by weight:

[0047] LLDPE resin: 100 parts;

[0048] LDPE resin: 30 parts;

[0049] EVA plastic: 30 parts;

[0050] Anti-ultraviolet anti-fog agent rGO / SiO 2 -g-PGMO: 10 parts;

[0051] The LLDPE resin is linear low density polyethylene, and LLDPE is usually produced by copolymerization of ethylene and higher alpha olefins such as butene, hexene or octene at lower temperature and pressure. The LLDPE polymer produced by the copolymerization process has a narrower molecular weight distribution than ordinary LDPE, and has a linear structure that makes it have different rheological properties. The melt flow characteristics of LLDPE adapt to the requirements of the new process, especially the film extrusion process, which can produce high-quality LLDPE products.

[0052] The LDPE resin is low-density polyethylene, and low-density polyethylene usually uses ethylene as a ...

Embodiment 3

[0061] An anti-ultraviolet and anti-fog polyethylene shed film, comprising the following components in parts by weight:

[0062] LLDPE resin: 100 parts;

[0063]LDPE resin: 30 parts;

[0064] EVA plastic: 30 parts;

[0065] Anti-ultraviolet anti-fog agent rGO / SiO 2 -g-PGMO: 15 parts;

[0066] The LLDPE resin is linear low density polyethylene, and LLDPE is usually produced by copolymerization of ethylene and higher alpha olefins such as butene, hexene or octene at lower temperature and pressure. The LLDPE polymer produced by the copolymerization process has a narrower molecular weight distribution than ordinary LDPE, and has a linear structure that makes it have different rheological properties. The melt flow characteristics of LLDPE adapt to the requirements of the new process, especially the film extrusion process, which can produce high-quality LLDPE products.

[0067] The LDPE resin is low-density polyethylene, and low-density polyethylene usually uses ethylene as a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com