A kind of anti-ultraviolet and anti-fog polyethylene shed film and preparation method thereof

A technology of anti-ultraviolet and polyethylene, applied in the field of materials, can solve the problems of not being able to prevent fog, and achieve the effect of promoting refinement and significant barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

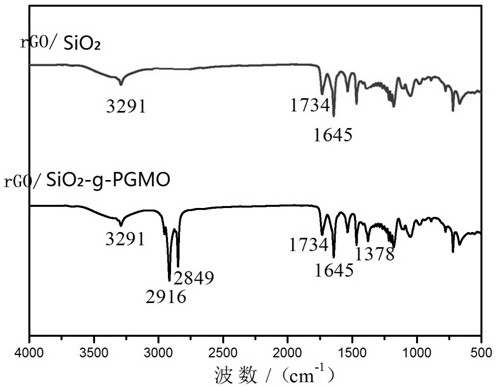

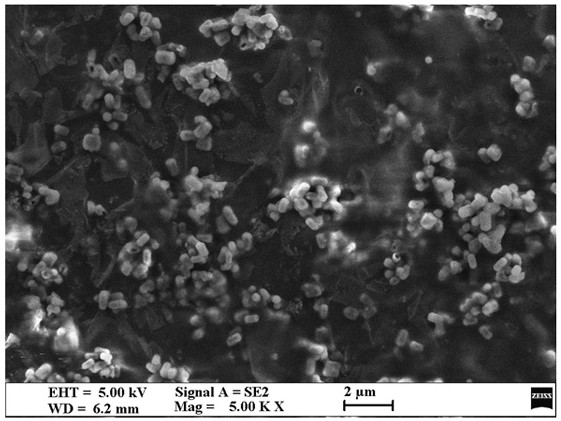

Method used

Image

Examples

Embodiment 1

[0031] A anti-ultraviolet anti-fog polyethylene shed membrane, including components of the following weight parts:

[0032] LLDPE resin: 100 parts;

[0033] LDPE resin: 30 copies;

[0034] EVA Plastics: 30 copies;

[0035] UV anti-fogl RGO / SiO 2 -g-pgmo: 5 copies;

[0036] The LLDPE resin is a linear low density polyethylene, and LLDPE is typically generated by a lower temperature and pressure, and is generated from ethylene and advanced A olefins such as butene, hexene or orthoson. The LLDPE polymer generated by the copolymerization process has a narrower amount of molecular weight than a general LDPE, and has a linear structure that has different rheological properties. LLDPE's molten flow characteristics adapt to new processes, especially with thin film extrusion processes, high quality LLDPE products.

[0037] The LDPE resin is a low density polyethylene, and the low density polyethylene is usually in ethylene as a monomer, under high pressure of 98. 0 to 294 MPa, an oxygen ...

Embodiment 2

[0046] A anti-ultraviolet anti-fog polyethylene shed membrane, including components of the following weight parts:

[0047] LLDPE resin: 100 parts;

[0048] LDPE resin: 30 copies;

[0049] EVA Plastics: 30 copies;

[0050] UV anti-fogl RGO / SiO 2 -g-pgmo: 10 copies;

[0051] The LLDPE resin is a linear low density polyethylene, and LLDPE is typically generated by a lower temperature and pressure, and is generated from ethylene and advanced A olefins such as butene, hexene or orthoson. The LLDPE polymer generated by the copolymerization process has a narrower amount of molecular weight than a general LDPE, and has a linear structure that has different rheological properties. LLDPE's molten flow characteristics adapt to new processes, especially with thin film extrusion processes, high quality LLDPE products.

[0052] The LDPE resin is a low density polyethylene, and the low density polyethylene is usually in ethylene as a monomer, under high pressure of 98. 0 to 294 MPa, an oxygen...

Embodiment 3

[0061] A anti-ultraviolet anti-fog polyethylene shed membrane, including components of the following weight parts:

[0062] LLDPE resin: 100 parts;

[0063]LDPE resin: 30 copies;

[0064] EVA Plastics: 30 copies;

[0065] UV anti-fogl RGO / SiO 2 -g-pgmo: 15 copies;

[0066] The LLDPE resin is a linear low density polyethylene, and LLDPE is typically generated by a lower temperature and pressure, and is generated from ethylene and advanced A olefins such as butene, hexene or orthoson. The LLDPE polymer generated by the copolymerization process has a narrower amount of molecular weight than a general LDPE, and has a linear structure that has different rheological properties. LLDPE's molten flow characteristics adapt to new processes, especially with thin film extrusion processes, high quality LLDPE products.

[0067] The LDPE resin is a low density polyethylene, and the low density polyethylene is usually in ethylene as a monomer, under high pressure of 98. 0 to 294 MPa, an oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com