High-strength steel for seat slide rails and method for producing the same based on thin strip casting-rolling

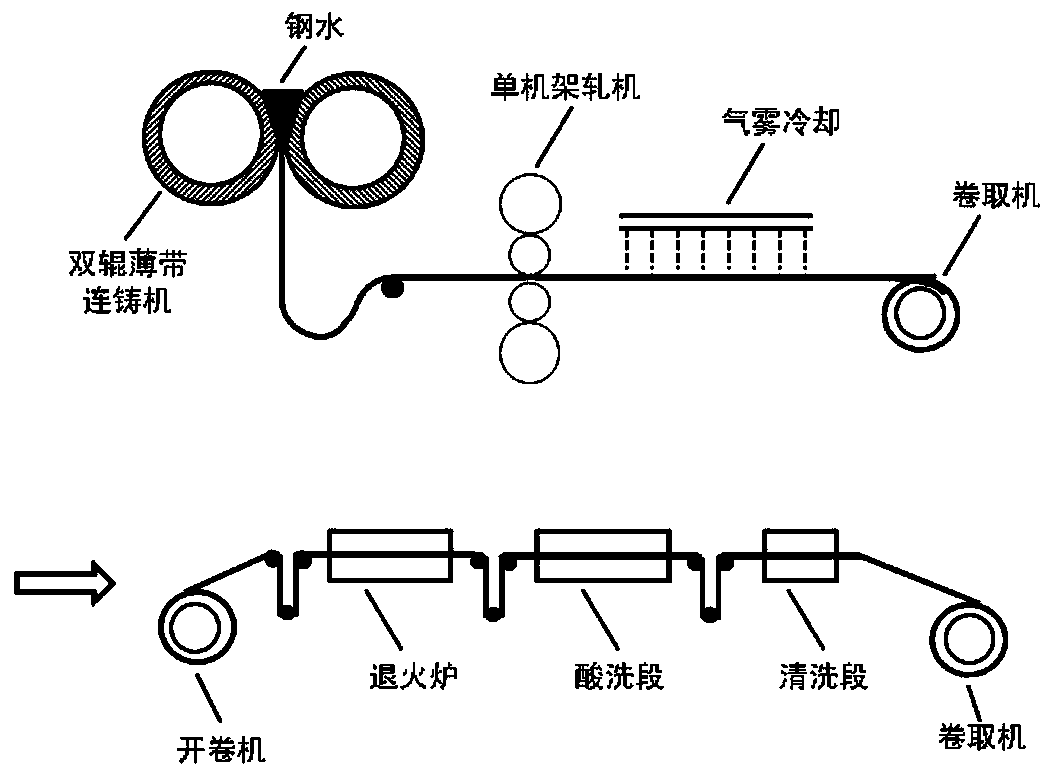

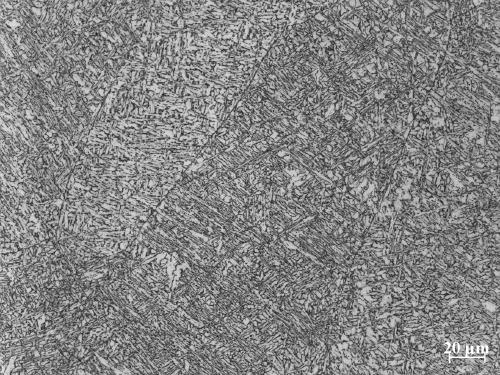

A thin strip casting and rolling, high-strength technology, applied in the field of steel production, can solve the problems of difficult to achieve performance and dimensional accuracy, long production process of cold-rolled high-strength steel, lower production costs, etc. Good uniformity and good isotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Smelting: In step (1), use electric furnace steelmaking, VD vacuum decarburization and deoxidation, and LF refining to obtain molten steel with qualified components.

[0056] Among them, the composition of molten steel by weight percentage is: C: 0.030, Mn: 1.45, Si: 0.37, Cr: 0.28, Nb: 0.068, V: 0.032, P: 0.012, S: 0.002, Al: 0.002, and the balance is Fe and impurity elements.

[0057] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by thin strip casting and rolling equipment. Under the protection of inert gas, the exemplary casting and rolling speed is 67m / min to obtain a cast strip with a thickness of 1.85mm.

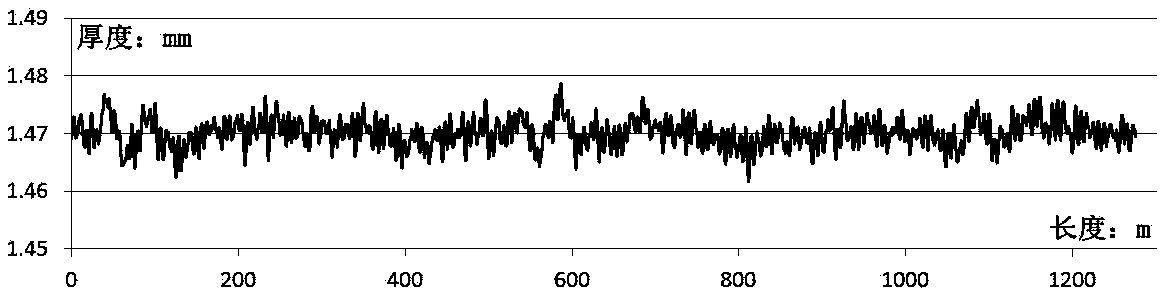

[0058] (3) Hot rolling: the cast strip is rolled into a thin strip of 1.47mm through one pass of hot rolling with a reduction of 21%, and the temperature at the exit of the rolling mill is 825°C.

[0059] (4) Cooling and coiling: The hot-rolled strip is cooled by an air-mist cooling system, and then coiled...

Embodiment 2

[0070] (1) Smelting: In the step (1), adopt electric furnace steelmaking, VD vacuum decarburization and deoxidation, and LF refining to obtain molten steel with qualified components. Percentage by weight: C: 0.026, Mn: 1.37, Si: 0.42, Cr: 0.22, Nb: 0.074, V: 0.038, P: 0.015, S: 0.003, Al: 0.003, and the balance is Fe and impurity elements.

[0071] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by thin strip casting and rolling equipment. Under the protection of inert gas, the casting and rolling speed is 62m / min to obtain a cast strip with a thickness of 1.96mm.

[0072] (3) Hot rolling: the cast strip is rolled into a thin strip of 1.58mm through one pass of hot rolling with a reduction of 19%, and the temperature at the exit of the rolling mill is 808°C.

[0073] (4) Cooling and coiling: the hot-rolled strip is cooled by an air-mist cooling system, and then coiled at 410°C and air-cooled to room temperature to obtain a hot-...

Embodiment 3

[0084] (1) Smelting: In the step (1), converter steelmaking, VD vacuum decarburization and deoxidation, and LF refining are used to obtain molten steel with qualified components. Percentage by weight: C: 0.037, Mn: 1.58, Si: 0.35, Cr: 0.20, Nb: 0.056, V: 0.045, P: 0.011, S: 0.003, Al: 0.002, and the balance is Fe and impurity elements.

[0085] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by thin strip casting and rolling equipment. Under the protection of inert gas, the casting and rolling speed is 59m / min to obtain a cast strip with a thickness of 2.02mm.

[0086] (3) Hot rolling: the cast strip is rolled into a thin strip of 1.72mm through one pass of hot rolling with a reduction of 15%, and the temperature at the exit of the rolling mill is 848°C.

[0087] (4) Cooling and coiling: the hot-rolled strip is cooled by an air-mist cooling system, and then coiled at 396°C and air-cooled to room temperature to obtain a hot-roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com