A kind of aluminum matrix composite material and preparation method thereof

An aluminum-based composite material and a composite material technology are applied in the field of aluminum-based composite materials and their preparation, which can solve the problems of reduced fluidity of composite materials, low yield of aluminum-based composite materials, and scrapping, etc. The effect of good quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

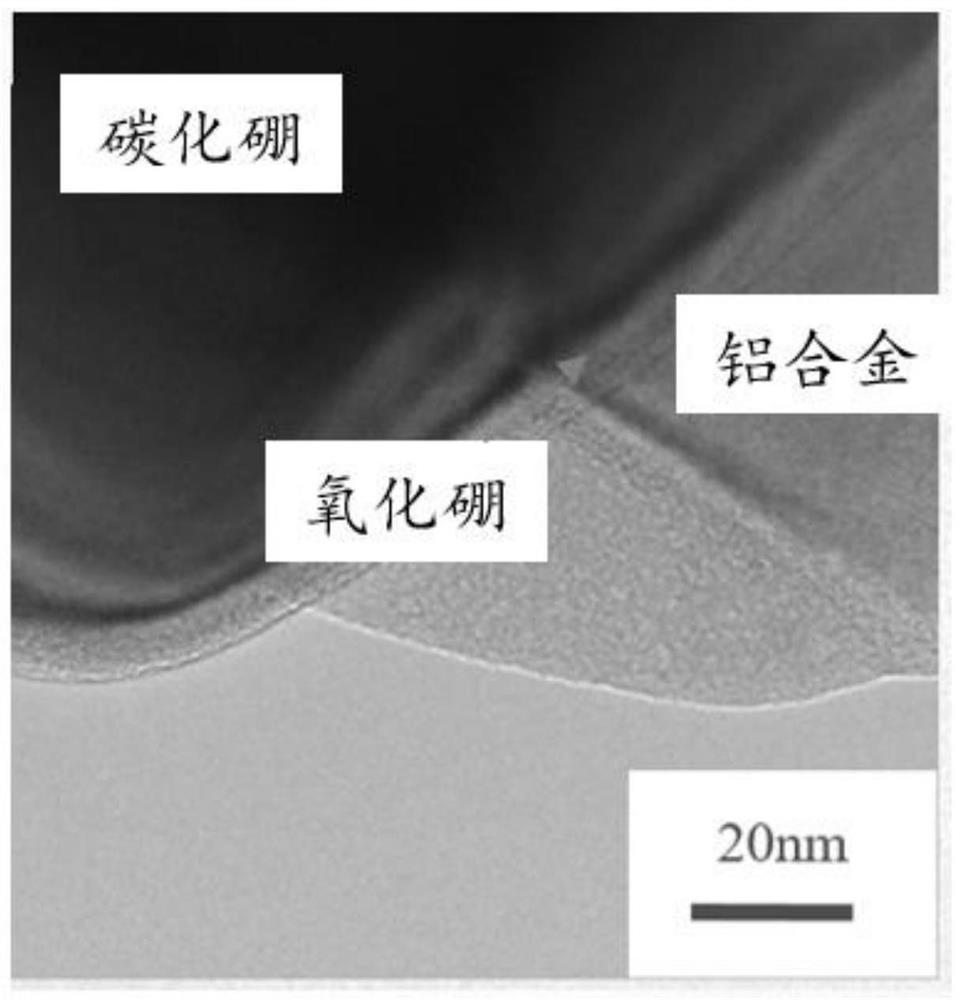

[0031] A method for preparing an aluminum-based composite material, the steps comprising:

[0032] (1) Surface treatment: first, wash the first boron carbide powder and the second boron carbide powder calculated according to the above ratio with water. Remove the inner and upper layer of water; repeat the above steps for 2 to 3 times; put the cleaned powder in a drying box for drying, the drying temperature is 40 ° C ~ 60 ° C, and the holding time is 18 h ~ 24 h; after drying The powder is heated in a furnace at a temperature of 400°C to 500°C, and the holding time is 1h to 2h to soften the surface of the particles, then take it out and cool it to room temperature for later use;

[0033] (2) Ball milling and mixing: the boron carbide powder obtained in step (1) is mixed with the first aluminum alloy powder, placed in a ball mill, and the speed of the ball mill is kept at 250-350 rpm for 2h-3h, Then add the second aluminum alloy powder into the ball mill and mix, keep the spee...

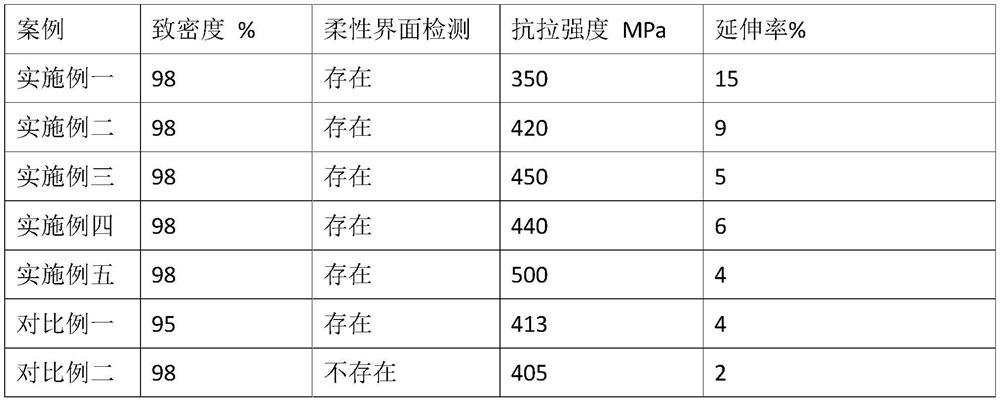

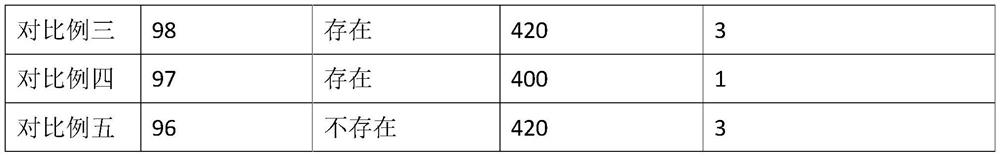

Embodiment 1

[0040] The aluminum-based composite material in this embodiment comprises 1% boron carbide and 99% aluminum alloy by volume percentage. The boron carbide particles include the first boron carbide with D50=15μm and the second boron carbide with D50=0.5μm. The volume ratio of the two specifications of boron carbide is 7:1; the aluminum alloy powder includes D 50 The first aluminum alloy and the average grain size D of 10 μm 50 The second aluminum alloy is 1 μm, the volume ratio of the two specifications of the aluminum alloy is 8:1, and the aluminum alloy matrix is 6 series aluminum alloy. Composite material is carried out according to the following steps in the present embodiment:

[0041] (1) Surface treatment of boron carbide particles: Firstly, wash the boron carbide powders of two specifications with water. The water body is removed, and this is repeated twice, and the cleaned powder is removed and placed in a drying box for drying. The temperature of the drying box is ...

Embodiment 2

[0048] The aluminum-based composite material in this embodiment comprises 10% boron carbide and 90% aluminum alloy by volume percentage. The boron carbide particles include the first boron carbide with D50=15μm and the second boron carbide with D50=0.5μm. The volume ratio of the two specifications of boron carbide is 8:1; the aluminum alloy powder includes D 50 The first aluminum alloy and the average grain size D of 10 μm 50 The second aluminum alloy is 1 μm, the volume ratio of the two specifications of the aluminum alloy is 7:1, and the aluminum alloy matrix is 6 series aluminum alloy. Composite material is carried out according to the following steps in the present embodiment:

[0049] (1) Surface treatment of boron carbide particles: Firstly, wash the boron carbide powders of two specifications with water. The water body is removed, and this is repeated twice, and the cleaned powder is removed and placed in a drying box for drying. The temperature of the drying box is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com