A non-contact ultrasonic brazing connection method for preparing quartz glass joints

A non-contact ultrasonic and quartz glass technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of large residual stress in high-temperature joints and difficult low-temperature connections, and achieve low production costs, high productivity, and simple connection processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] This non-contact ultrasonic brazing connection method for preparing quartz glass joints:

[0015] 1. The width of the solder foil is processed to be exactly the same as that of the quartz glass. The solder foil is Sn-(8~13)Zn-(0.1~5)Ti-(0.01~3)Al foil.

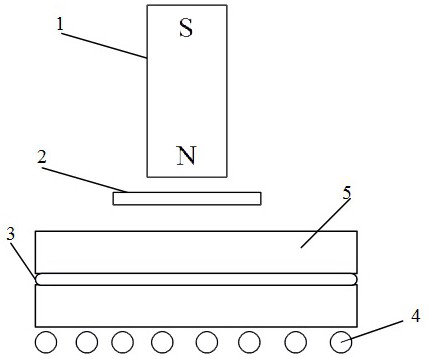

[0016] 2. Use sandpaper to grind the surface of the solder foil, wash it with acetone for 10-30 minutes, then fill the solder foil prepared in step 1 between the two surfaces of the quartz glass to be welded, and set it on the heating device 4, then raise the temperature to 100-400°C at a rate of 1-5°C / min, keep it warm for 5-10 minutes, and place it in a static magnetic field in a vertical direction. figure 1 , the permanent magnet 1 and the coil 2 are located directly above the liquid solder 3, the static magnetic field is generated by a superconducting magnet, and its magnetic induction is 1~12T, the coil genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com