Foaming agent material, foaming agent master batch and preparation method thereof

A technology of foaming agent and masterbatch, which is applied in the field of foaming agent masterbatch and its preparation, and foaming agent materials. It can solve the problems of limited application, low decomposition temperature of sodium bicarbonate, wide decomposition temperature range, etc., and reach the decomposition temperature The effect of narrow range, fine cells, fine and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of above-mentioned foaming agent masterbatch comprises: to the sodium bicarbonate foaming agent coated with borosilicate aluminosilicate synthesized in step (1) and base resin mix in proportion, add compatibilizer, antioxidant, The foaming agent masterbatch is obtained by granulating with a granulator.

[0042] The granulation can be carried out by using a twin-screw extruder, the processing temperature of the twin-screw extruder is between 120-220°C, the screw speed is 100-300rpm, and the blowing agent component is fed through two-stage side feeding .

Embodiment 1

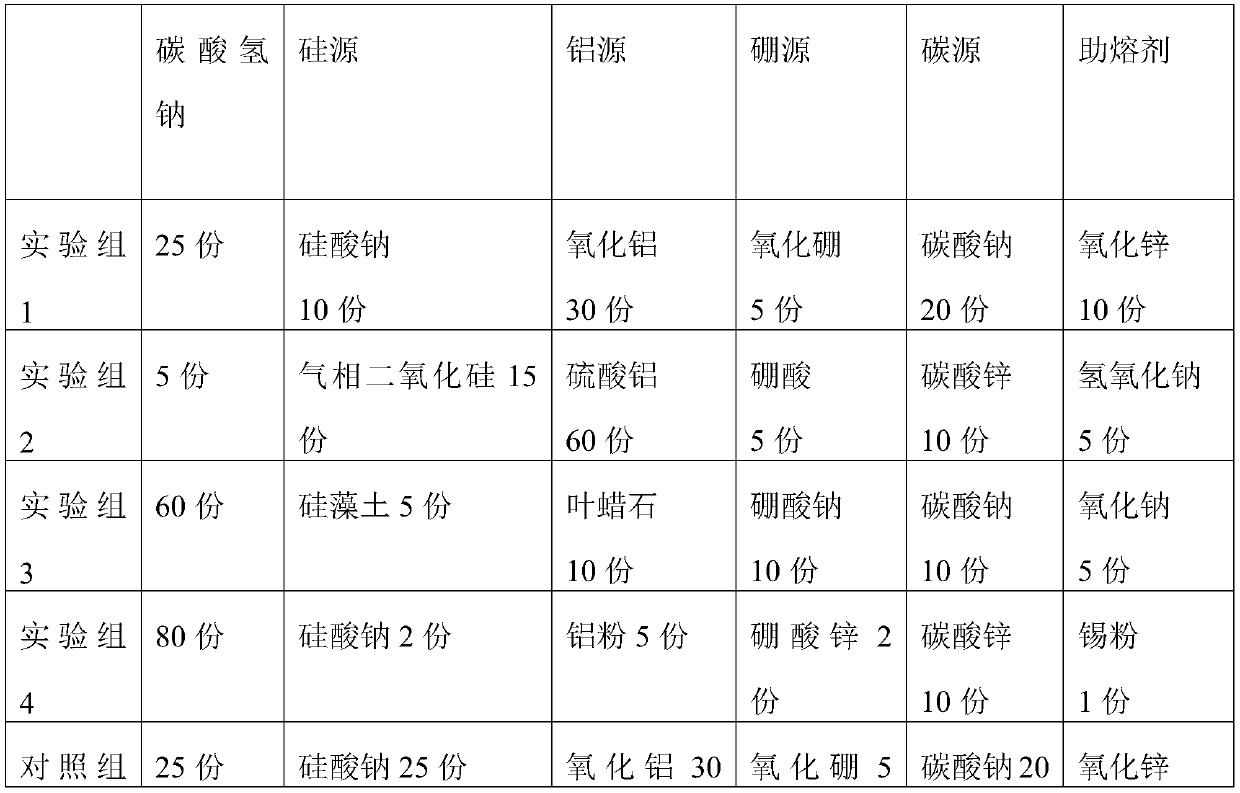

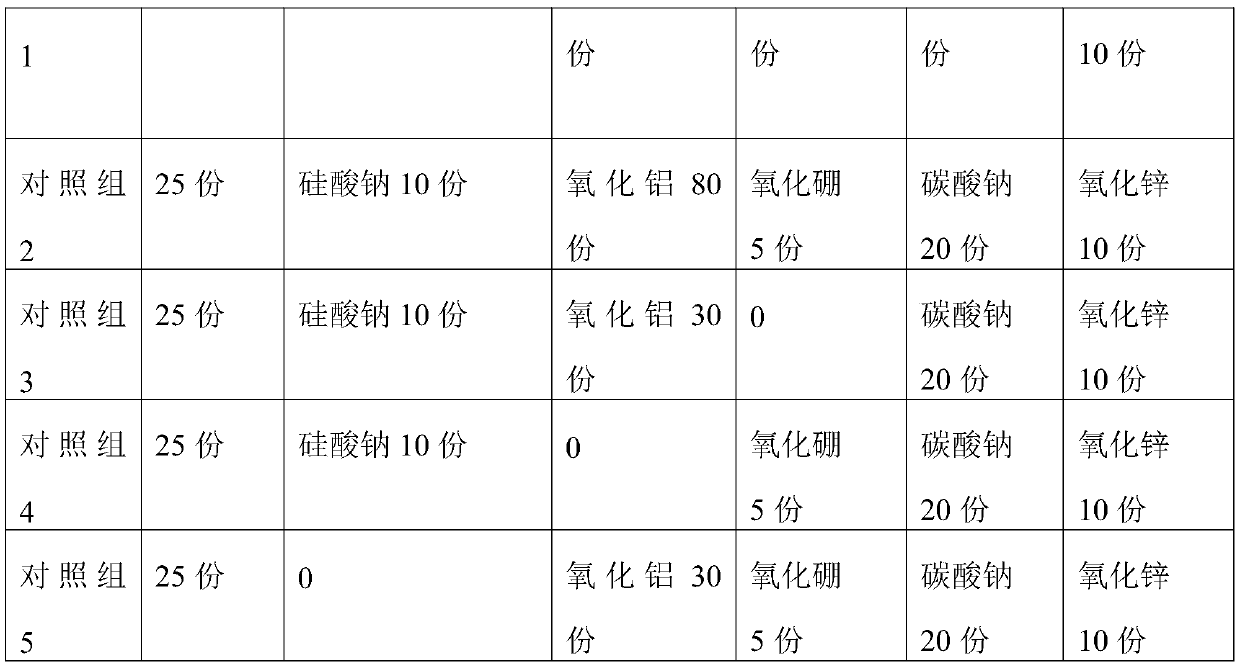

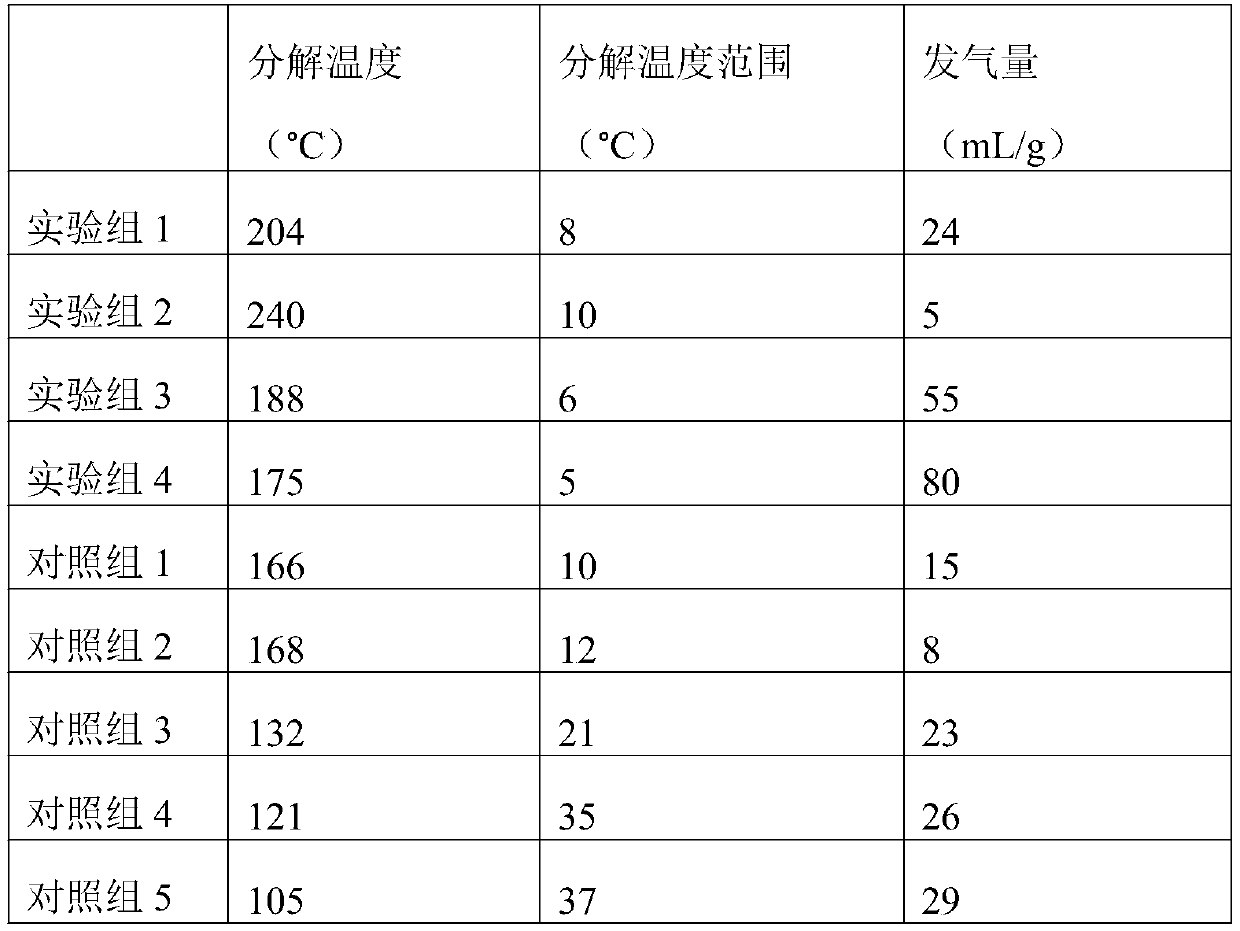

[0045] Embodiment 1 provides a kind of blowing agent material, the blowing agent material provided is by mixing sodium bicarbonate, silicon source, aluminum source, boron source, carbon source and fluxing agent in proportion, and then utilizes grinder to grind, Grind until the D50 of the powder reaches below 30 microns; mature the powder in saturated water vapor at 100 degrees Celsius for 100 minutes, and then continue to age the powder in air at 100 degrees Celsius for 100 minutes to make the surface of sodium bicarbonate react to form borosilicate-alumino-silicate A coating layer of salt to obtain the corresponding blowing agent material. Wherein the raw materials used in each experimental group and the corresponding content are respectively as shown in the following table 1 (the number of parts of each raw material is shown according to the quality in table 1):

[0046] Raw materials and their proportions used by each experimental group in table 1

[0047]

[0048]

...

Embodiment 2

[0055] Example 2 Taking the raw materials of Experimental Group 1 in Example 1 as a reference, the effect of changing the aging treatment conditions on the foaming agent material during the preparation of the foaming agent material was studied.

[0056] Experimental group a

[0057] The powder was matured in saturated water vapor at 100 degrees Celsius for 4 hours, and it was found that the powder had serious agglomeration, and the agglomeration size reached the millimeter level. The powder of this size is difficult to disperse well in the plastic melt, and the cell size is difficult to control during the foaming process.

[0058] Experimental group b

[0059] The powder was aged directly in the air at 100 degrees Celsius for 4 hours, and it was found that the decomposition temperature of the foaming agent was 174 degrees Celsius, and the temperature range of the foaming agent was 36 degrees Celsius. The decomposition temperature is lower than the result of the experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com