A kind of preparation method of dendritic hollow zinc oxide nanorod array

A technology of zinc oxide nanorods and nanorod arrays, which is applied in the field of materials science and engineering, can solve the problems of inability to effectively control the morphology of dendritic zinc oxide nanorod arrays, high reaction temperature, and limited development, so as to improve the repeatability of experiments , Simplify the experimental steps, the effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

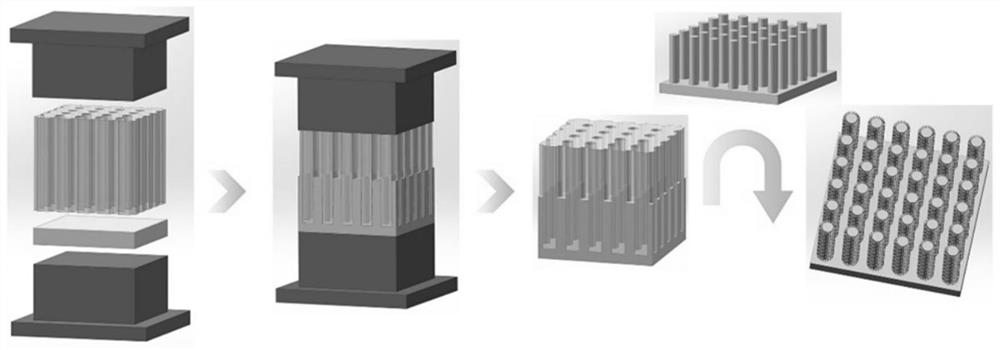

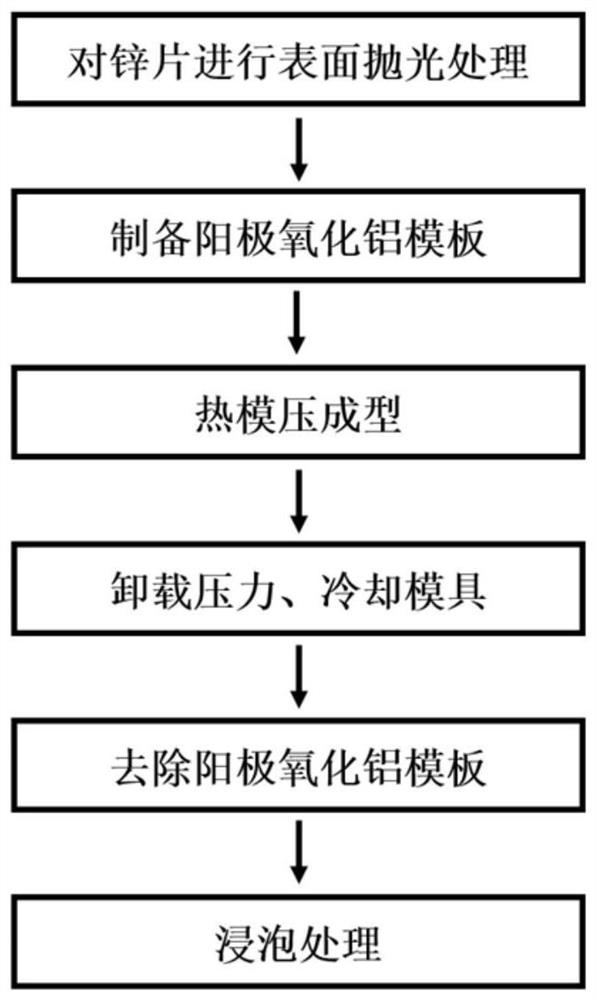

[0036] A method for preparing a dendritic hollow zinc oxide nanorod array, comprising the steps of:

[0037] 1) Surface treatment of the zinc flakes: Mechanically polish or electrochemically polish one side of the zinc flakes to obtain a zinc flake with a smooth surface on one side, and place the zinc flakes with the polished side up in acetone, absolute ethanol, deionized Ultrasonic cleaning is carried out in water in turn, and it is taken out and dried for use;

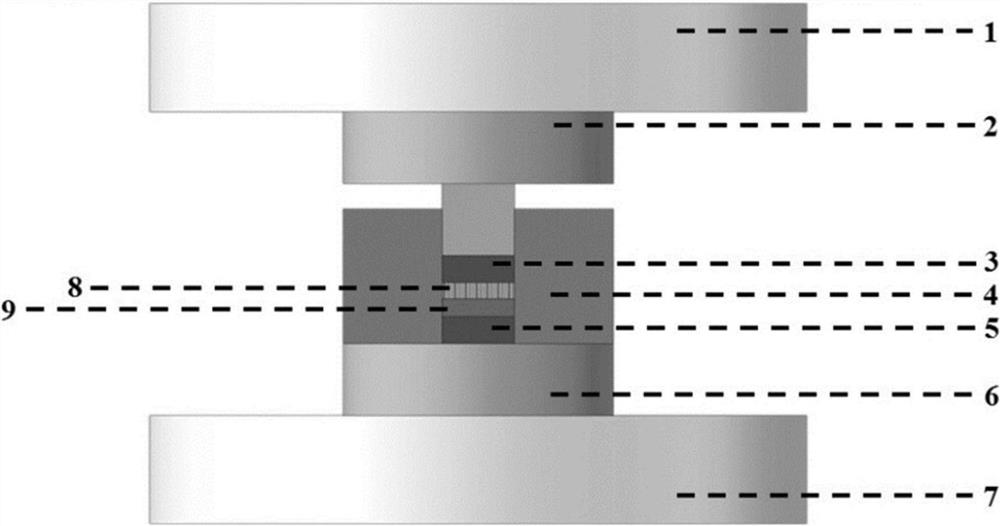

[0038] 2) Hot molding: the smooth surface of the polished zinc sheet in step 1 is stacked with the commercial double-pass porous anodized aluminum template, and then placed in the mold for fixing. Heat the mold to a temperature higher than the recrystallization temperature of zinc, and keep it for a period of time, so that the temperature of the template and the zinc sheet are consistent, and then apply a certain pressure, which should be greater than the yield strength of zinc at this temperature, and under this te...

Embodiment 1

[0050] Fabrication of zinc nanorod arrays with diameters of 50–400 nm by thermocompression molding:

[0051] Cut the zinc flakes into discs with a diameter of 5 mm by a punching machine, mechanically polish the zinc flakes with a diameter of 5 mm, and then perform ultrasonic cleaning repeatedly in acetone, absolute ethanol, and deionized water respectively, take them out and dry them for use.

[0052] The double-pass porous anodized alumina prepared by the secondary oxidation method is used as a template, the aperture of the template is 50-400nm, the hole depth is 60μm, and the template is a nanoporous ordered array with uniform distribution of holes.

[0053] Place the lower steel mold 8 on the lower indenter 9 of the universal testing machine, the limiting sleeve 3 and the lower steel mold 8 are positioned and fixed through the central cylinder and hole of the lower steel mold 8, and then put the lower pad 7 into the limiting sleeve In the small hole, place the zinc sheet 6 ...

Embodiment 2

[0056] Zinc nanorod arrays with a diameter of 200 nm and different lengths were fabricated by compression molding:

[0057] Cut the zinc flakes into discs with a diameter of 5 mm by a punching machine, mechanically polish the zinc flakes with a diameter of 5 mm, and then perform ultrasonic cleaning repeatedly in acetone, absolute ethanol, and deionized water respectively, take them out and dry them for use.

[0058] Double-pass porous anodized aluminum prepared by a secondary oxidation method is used as a template, and the template is a nanoporous ordered array with a pore diameter of 50-400nm, a pore depth of 60μm, and uniform distribution of pores.

[0059] Place the lower steel mold 8 on the lower indenter 9 of the universal testing machine, the limiting sleeve 3 and the lower steel mold 8 are positioned and fixed through the central cylinder and hole of the lower steel mold 8, and then put the lower pad 7 into the limiting sleeve In the small hole, place the zinc sheet 6 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com