A method and system for recovering elemental sulfur and regenerating catalysts loaded with sulfur

A technology of catalyst and recovery sheet, which is applied in the field of recovery of elemental sulfur and regeneration of sulfur-loaded catalysts. It can solve the problems of difficult control of by-products, high energy consumption, and influence of operating temperature, and achieve simple system equipment and production processes. Safe and reliable, good energy saving and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

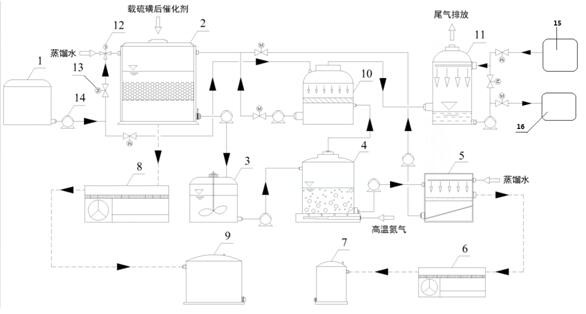

[0037]A system for recovering and regenerating elemental sulfur by catalysts loaded with sulfur, comprising ammonia sulfide storage tank 1, sulfur leaching reactor 2, ammonia polysulfide storage tank 3, elemental sulfur stripping reactor 4, solid-liquid separator 5, elemental sulfur Sulfur drier 6, sulfur storage tank 7, catalyst drier 8, catalyst storage tank 9, cooling tower 10, tail gas purification tower 11, lye tank 15, waste liquid tank 16; The top of the reactor 2 is connected, and a three-way solenoid valve 12 and a two-way electric valve 13 are arranged between the pump 14 and the sulfur leaching reactor 2. The three-way solenoid valve 12 is also connected with the distilled water inlet, and the top of the sulfur leaching reactor 2 is provided with Sulfur-loaded catalyst inlet; the bottom of the sulfur leaching reactor 2 is connected to the ammonia polysulfide storage tank 3 through a pump, the ammonia polysulfide storage tank 3 is connected to the elemental sulfur gas...

Embodiment 2

[0047] Adopt the system of embodiment 1, after carrying out carrying out sulfur, catalyst reclaims elemental sulfur and regenerates, concrete steps are as follows:

[0048] (1) Efficient normal temperature and pressure immersion extraction of sulfur in ammonium sulfide solution:

[0049] The catalyst is Co 15 Mo 10 / Al 2 o 3 catalytic reduction of SO 2 For the subsequent catalyst, the sulfur-loaded catalyst is added to the sulfur leaching reactor 2 from the sulfur-loaded catalyst inlet, the two-way electric valve 13 is opened, the three-way solenoid valve 12 is connected to the pump 14 and the sulfur leaching reactor 2, and the sulfurized The ammonia sulfide solution in the ammonia storage tank 1 is pumped into the sulfur leaching reactor 2. The mass fraction of the ammonia sulfide solution is 18%. The volume ratio is 1:5, under normal temperature and pressure, let the leaching reaction stand for 8 hours, wait for the leaching to be completed, pump the leaching solution, ...

Embodiment 3

[0056] Adopt the system of embodiment 1, after carrying out carrying out sulfur, catalyst reclaims elemental sulfur and regenerates, concrete steps are as follows:

[0057] (1) Efficient normal temperature and pressure immersion extraction of sulfur in ammonium sulfide solution:

[0058] The catalyst is Co 15 Mo 10 / Al 2 o 3 catalytic reduction of SO 2 For the subsequent catalyst, the sulfur-loaded catalyst is added to the sulfur leaching reactor 2 from the sulfur-loaded catalyst inlet, the two-way electric valve 13 is opened, the three-way solenoid valve 12 is connected to the pump 14 and the sulfur leaching reactor 2, and the sulfurized The ammonia sulfide solution in the ammonia storage tank 1 is pumped into the sulfur leaching reactor 2. The mass fraction of the ammonia sulfide solution is 20%. The volume ratio is 1:6, under normal temperature and pressure, let the leaching reaction stand for 10 hours, wait until the leaching is completed, pump the leaching solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com