A kind of titanium alloy thin plate and processing method thereof

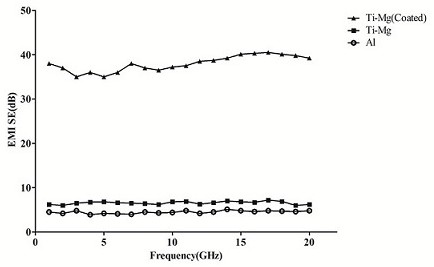

A processing method, titanium alloy technology, applied in the field of alloys, can solve problems such as poor shielding effect, avoiding weak electromagnetic interference, and generation of pores, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The titanium alloy in this embodiment includes the following raw materials in parts by weight: 80 parts of titanium powder, 60 parts of magnesium powder, 17 parts of urea, 13 parts of ammonium bicarbonate, 8 parts of silicon carbide, and 7 parts of synthetic wax.

[0029] Among them, the cladding powder is composed of lead iodide powder and tungsten carbide powder, and the composition and particle size are shown in the table below.

[0030] lead iodide Tungsten carbide Composition % 20 80 purity% 99.99 99.96 Particle size (mesh) 150 260

Embodiment 2

[0032] The titanium alloy in this embodiment includes the following raw materials in parts by weight: 84 parts of titanium powder, 63 parts of magnesium powder, 18 parts of urea, 14 parts of ammonium bicarbonate, 10 parts of silicon carbide, and 12 parts of synthetic wax.

[0033] Among them, the cladding powder is composed of lead iodide powder and tungsten carbide powder, and the composition and particle size are shown in the table below.

[0034] lead iodide Tungsten carbide Composition % 25 75 purity% 99.90 99.90 Particle size (mesh) 200 200

Embodiment 3

[0036] The titanium alloy in this embodiment includes the following raw materials in parts by weight: 85 parts of titanium powder, 70 parts of magnesium powder, 19 parts of urea, 15 parts of ammonium bicarbonate, 12 parts of silicon carbide, and 8 parts of synthetic wax.

[0037] Among them, the cladding powder is composed of lead iodide powder and tungsten carbide powder, and the composition and particle size are shown in the table below.

[0038] lead iodide Tungsten carbide Composition % 23 78 purity% 99.95 99.97 Particle size (mesh) 170 180

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com