Silanized reduced graphene oxide-titanium dioxide composite material, and preparation method and application thereof

A technology of titanium dioxide and composite materials, which is applied in the field of water pollution treatment, can solve the problems of reducing the adsorption performance of composite materials to pollutants, the solubility of composite materials, and restricting the application, so as to enhance the photocatalytic performance, improve the adsorption performance, and reduce the content of Cd2+. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

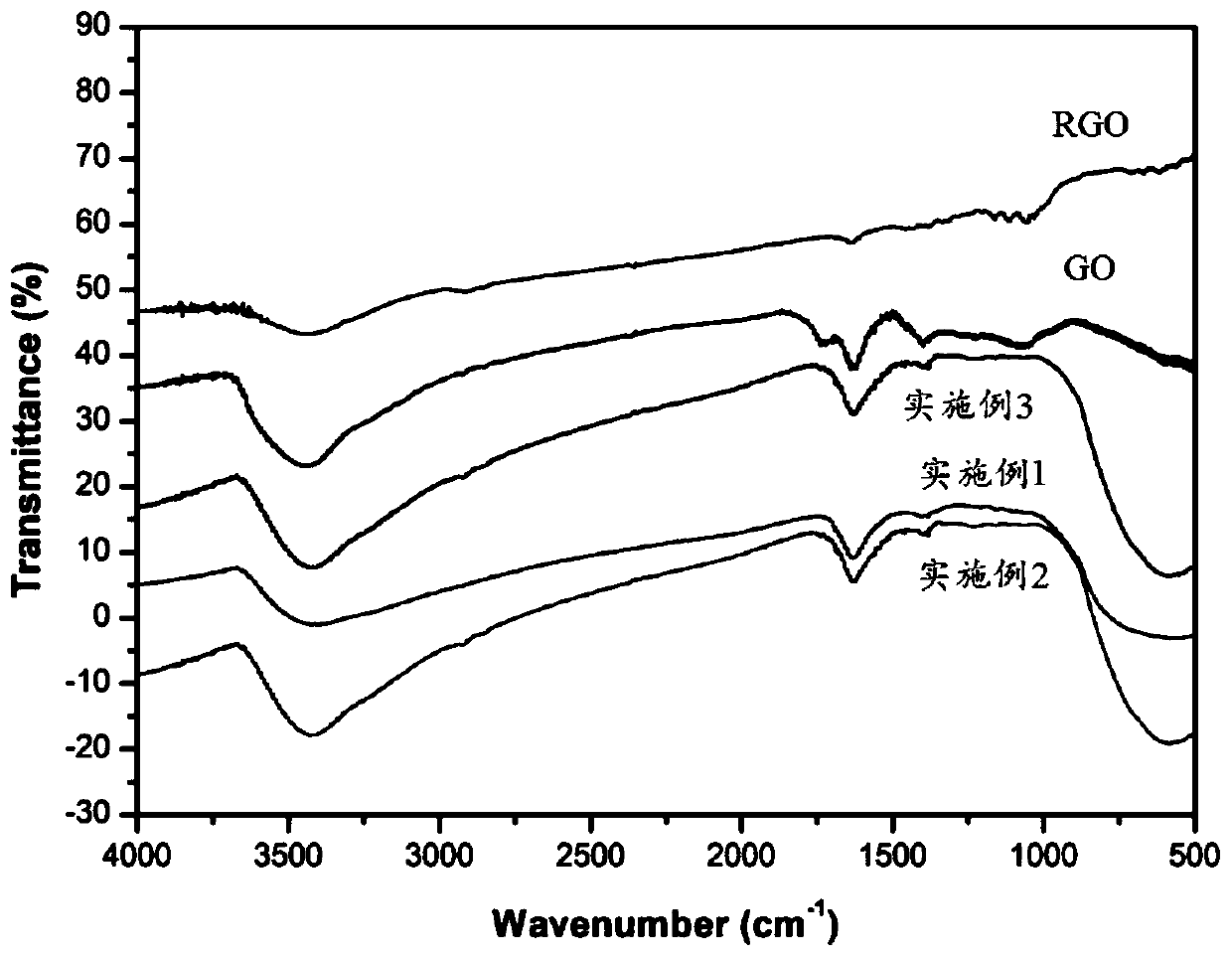

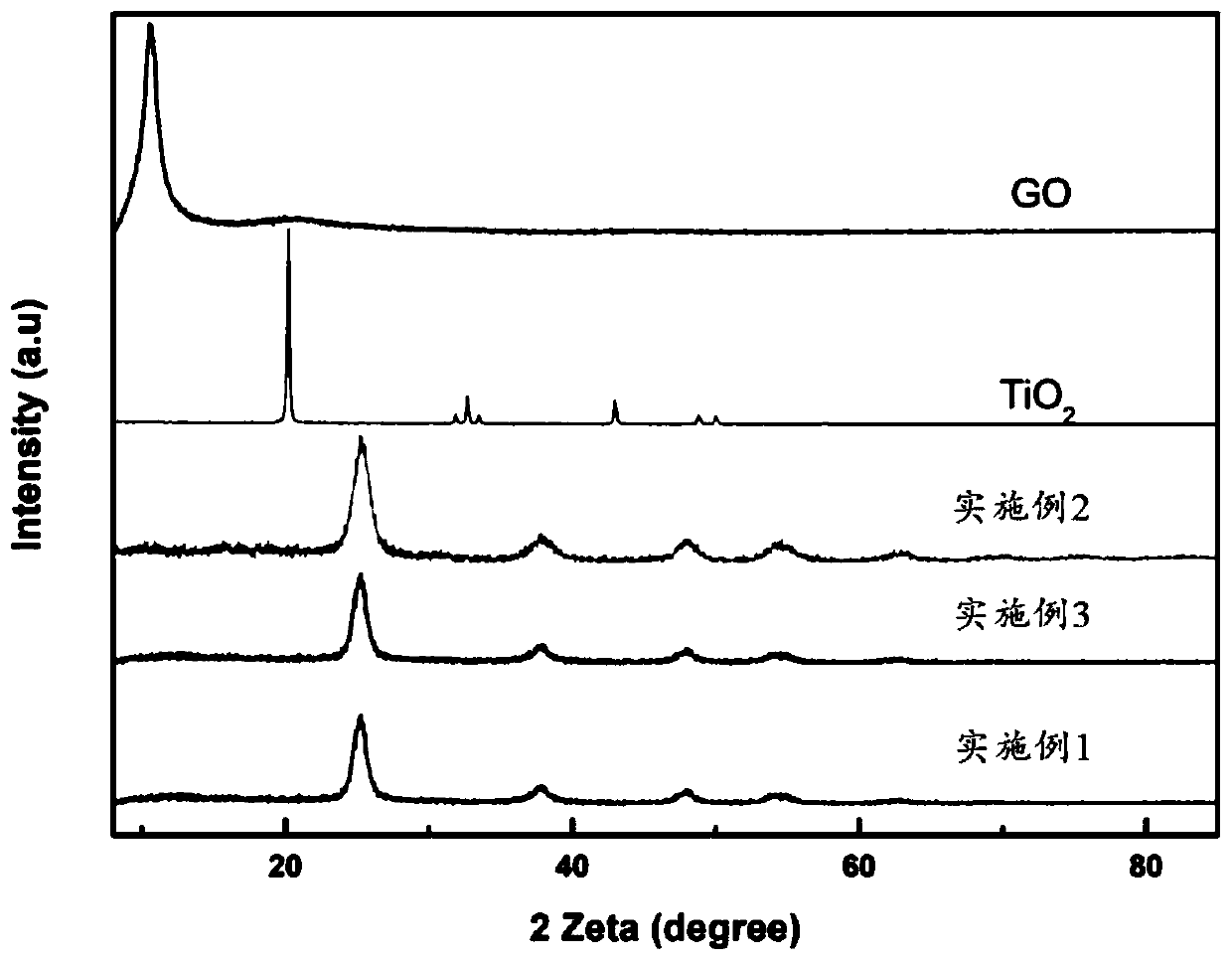

[0033] The present invention provides a kind of preparation method of silanization reduction graphene oxide titanium dioxide composite material, comprises the following steps:

[0034] (1) Stir after mixing the tetrabutyl titanate solution and the graphene oxide aqueous dispersion, then remove the solvent to obtain the graphene oxide / titanium dioxide composite material;

[0035] (2) dispersing the graphene oxide / titanium dioxide composite material in a polar organic solvent to obtain a graphene oxide / titanium dioxide dispersion;

[0036] (3) Graphene oxide / titanium dioxide dispersion liquid and N-(trimethoxysilylpropyl) sodium ethylenediamine triacetate are mixed, carry out heating reaction, then add methanol in reaction liquid, carry out hydrothermal reaction again, A silylated-reduced graphene oxide-titanium dioxide composite material was obtained.

[0037] In the invention, the tetrabutyl titanate solution and the graphene oxide aqueous dispersion are mixed, stirred, and t...

Embodiment 1

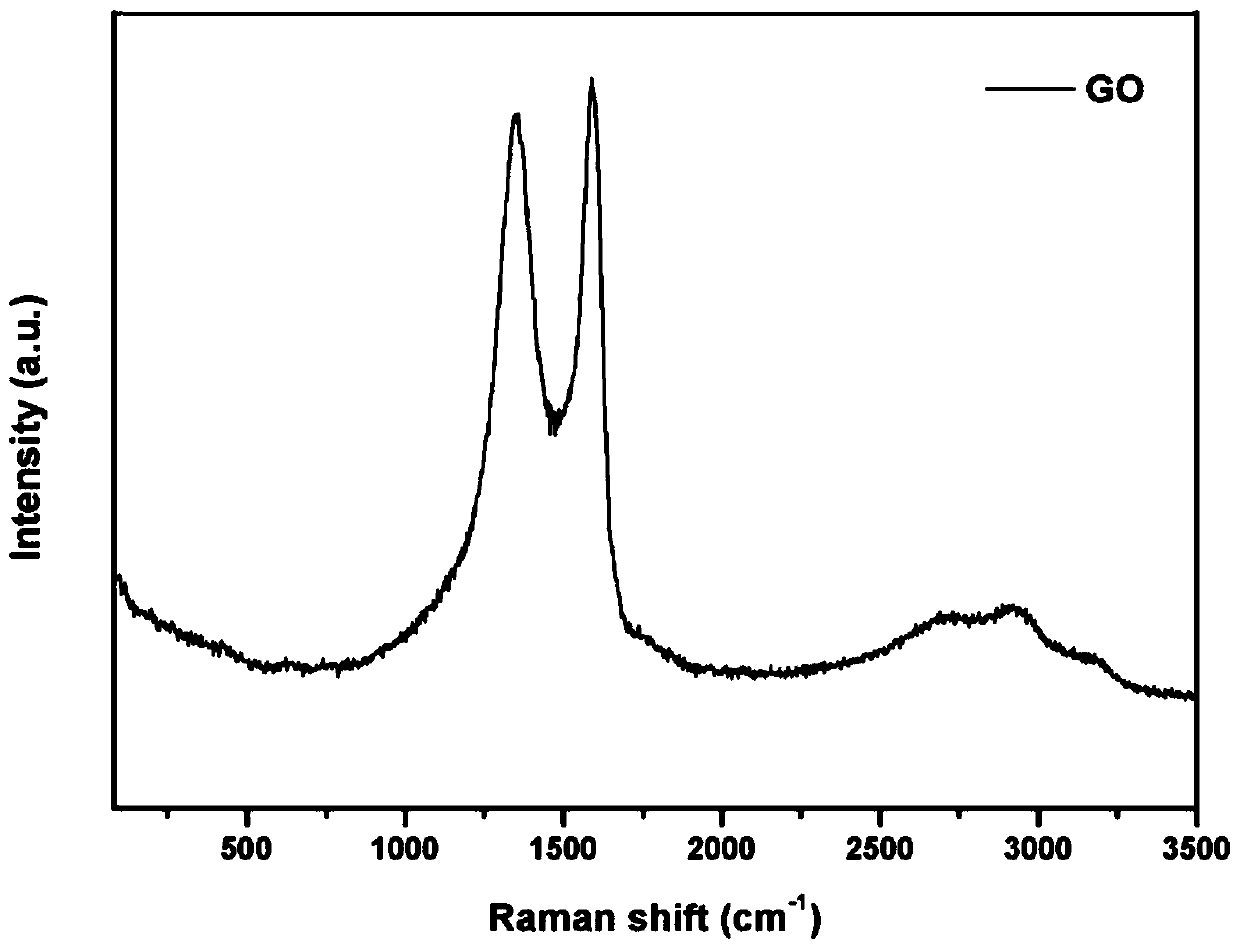

[0053] (1) Prepare graphene oxide by improved Hummers method

[0054] Slowly dissolve 2g of sodium nitrate and 2g of graphite in 92mL of commercially available concentrated sulfuric acid, and continuously stir in an ice-water bath for 4h, then slowly add 12g of potassium permanganate while keeping the temperature below 20°C, and then stir at room temperature until Unable to stir, then add 200mL deionized water dropwise, stir at about 90°C for 10min, cool to room temperature, add 20mL hydrogen peroxide dropwise, the solution is bright yellow, after standing for a day, use 10% volume fraction of dilute hydrochloric acid and deionized water Centrifugal cleaning to neutrality, freeze-drying to obtain graphene oxide.

[0055] (2) Preparation of graphene oxide / titanium dioxide composites

[0056] Slowly add 2.2 mL of tetrabutyl titanate into 40 mL of absolute ethanol, stir for 40 minutes to mix evenly, and record it as liquid A; then add 50 mg of graphene oxide into 15 mL of deioni...

Embodiment 2

[0060] (1) prepare graphene oxide according to the method for embodiment 1;

[0061] (2) Slowly add 3.5mL of tetrabutyl titanate into 35mL of absolute ethanol, stir for 20min to mix evenly, and record it as liquid A; then add 70mg of graphene oxide into 10mL of deionized water, and ultrasonically disperse to obtain graphene oxide Dispersion liquid, then keep the dispersion liquid stirring state, slowly add liquid A into it, after the addition is completed, continue to stir the reaction for 1h, and finally stop stirring, rotate steam at 60°C, collect the residue of rotary evaporation, and freeze-dry to obtain graphene oxide / Titanium dioxide composite material;

[0062] (3) Add 50 mg of graphene oxide / titanium dioxide composite material to 50 mL of ethanol, and disperse it by ultrasonic treatment for 2 h; Sodium acetate aqueous solution (abbreviated as EDTA-silane), and stirred at 55°C for 12h; after the reaction was completed, 80mL of methanol was added to dilute unreacted s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com