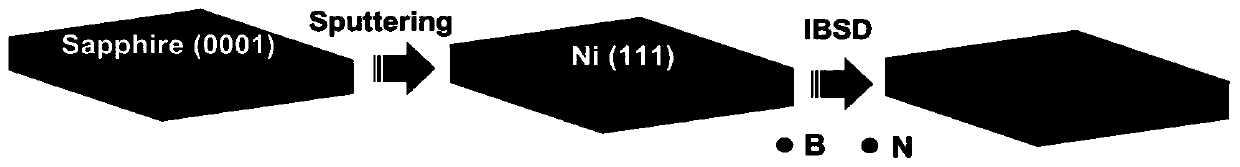

Method for obtaining single-crystal boron nitride film by ion beam sputtering deposition

An ion beam sputtering, boron nitride technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of affecting film performance, unfavorable large-scale production, complex and unclear growth mechanism, etc. Controllable number of layers, improved high-cost and highly toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Use acetone, ethanol and deionized water to ultrasonically clean the c-plane sapphire substrate for 10 minutes in sequence, rinse with deionized water after each cleaning, and finally dry in an incubator;

[0031] b. immerse the cleaned sapphire substrate in a hydrofluoric acid solution (10% by mass fraction) for 30s, rinse with deionized water, and put the substrate into a vacuum oven to dry;

[0032] c. Place a high-purity Ni target (purity of 99.99%) on the target position of a DC magnetron sputtering instrument, and epitaxially grow it on a sapphire substrate heated to 600°C with a constant power of 50W in an argon atmosphere for 2.5 μm thick Ni(111) oriented film;

[0033] d. Fix the sputtered Ni / sapphire substrate on the sample holder and place it in the growth chamber, vacuum the chamber to 3.75×10-3mTor, and inject 50sccm hydrogen gas into the reaction chamber to raise the pressure to 30mTor , increase the heating current to raise the substrate temperature t...

Embodiment 2

[0038] a. Use acetone, ethanol and deionized water to ultrasonically clean the c-plane sapphire substrate for 10 minutes in sequence, rinse with deionized water after each cleaning, and finally dry in an incubator;

[0039] b. immerse the cleaned sapphire substrate in a hydrofluoric acid solution (10% by mass fraction) for 30s, rinse with deionized water, and put the substrate into a vacuum oven to dry;

[0040] c. Place a high-purity Ni target (purity of 99.99%) on the target position of a DC magnetron sputtering instrument, and epitaxially grow 2.5 μm on a sapphire substrate heated to 600 °C with a constant power of 60 W in an argon atmosphere Thick Ni(111) oriented films;

[0041] d. Fix the sputtered Ni / sapphire substrate on the sample holder and put it into the growth chamber, vacuum the chamber to 3.75×10-3mTor, and feed 50sccm hydrogen gas into the reaction chamber to raise the pressure to 40mTor, Increase the heating current to raise the substrate temperature to 1050°...

Embodiment 3

[0046] a. Use acetone, ethanol and deionized water to ultrasonically clean the c-plane sapphire substrate for 10 minutes in sequence, rinse with deionized water after each cleaning, and finally dry in an incubator;

[0047] b. Immerse the cleaned c-plane sapphire substrate in a hydrofluoric acid solution (10% by mass) for 30 seconds, rinse with deionized water, and put the substrate into a vacuum drying oven to dry;

[0048] c. Place a high-purity Ni target (purity of 99.99%) on the target position of a DC magnetron sputtering apparatus, and epitaxially grow it on a sapphire substrate heated to 600 °C with a constant power of 70 W in an argon atmosphere for 2.5 μm thick Ni(111) oriented film;

[0049] d. Fix the sputtered Ni / sapphire substrate on the sample holder and put it into the growth chamber, vacuum the chamber to 3.75×10-3mTor, and inject 50sccm hydrogen gas into the reaction chamber to raise the pressure to 50mTor , increase the heating current to raise the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com