Argyrodite-doped perovskite solid electrolyte and preparation method thereof

A solid electrolyte and perovskite-type technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problem that the conductivity of the grain boundary is only 10-5S/cm, which cannot meet the actual needs, and achieve an improvement Migration performance, accelerated degradation of grain boundaries, and performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the second aspect of the present invention provides a method for preparing argentite-doped perovskite-type solid electrolyte material, comprising the following steps:

[0037] (1) According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 , 0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time, respectively weigh lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, simple substance of Ag, simple substance of Ge, simple substance of Se, and simple substance of Te in proportion, as Ingredients;

[0038] (2) carry out ball milling after described batching is mixed;

[0039] (3) pre-calcining the powder obtained by ball milling to obtain a precursor with a crystal structure;

[0040] (4) Carry out the second ball milling on the pre-calcined precursor to obtain fine particles, and press the particles into tablets;

[0041] (5) Carry out deglue processing to compressed tablet;

[0042] (6) Sintering the pressed tablet after...

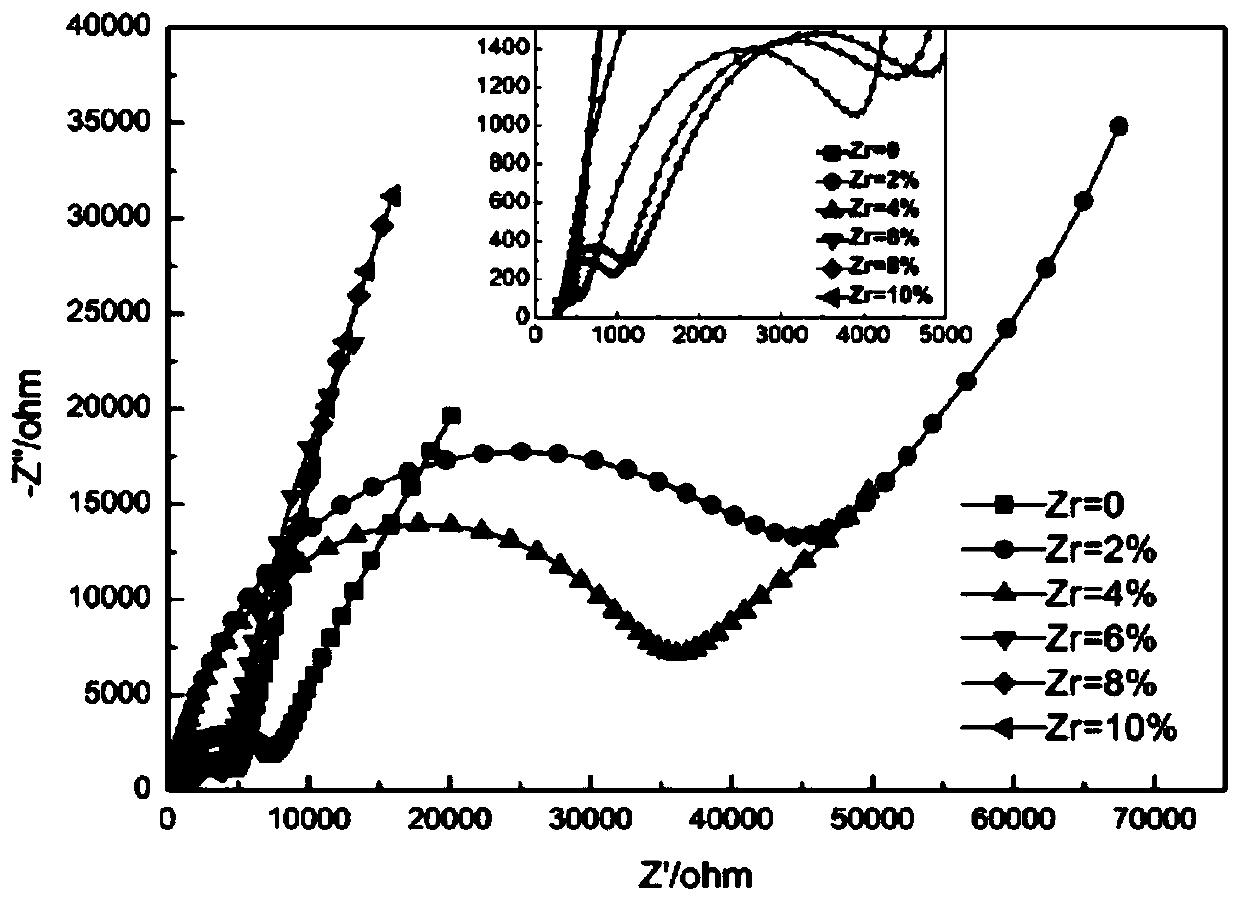

Embodiment 1

[0061] Embodiment 1 (argentite doping is arranged):

[0062] According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 (0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time) (wherein x=0.02, y=0.5) molar ratio Weigh lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, Ag simple substance, Ge simple substance, Se simple substance, and Te simple substance are prepared into a mixture and then vacuum-packed. Using absolute ethanol as a medium, put the mixture into a ball mill jar and mill it for 6-12 hours, dry the milled slurry, put it into a crucible, and calcinate it at 1100°C for 6-12 hours. After the pre-burning is completed, the obtained powder is subjected to secondary ball milling for 6-12 hours, and then the powder after the secondary ball milling is dried and placed in a mortar, 6% polyvinyl alcohol is added, and fine particles are fully ground to obtain fine particles. The good granules are placed on a tablet press to be pressed into t...

Embodiment 2

[0063] Embodiment 2 (argentite doping is arranged):

[0064] According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 (0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time) (wherein x=0.04, y=0.5) molar ratio Weigh lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, Ag simple substance, Ge simple substance, Se simple substance, and Te simple substance are prepared into a mixture and then vacuum-packed. Using absolute ethanol as a medium, put the mixture into a ball mill jar and mill it for 6-12 hours, dry the milled slurry, put it into a crucible, and calcinate it at 1100°C for 6-12 hours. After the pre-burning is completed, the obtained powder is subjected to secondary ball milling for 6-12 hours, and then the powder after the secondary ball milling is dried and placed in a mortar, 6% polyvinyl alcohol is added, and fine particles are fully ground to obtain fine particles. The good granules are placed on a tablet press to be pressed into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com