Bioadhesive temperature-sensitive material, preparation method thereof and application of drug carrier

A bioadhesive, temperature-sensitive material technology, used in drug combination, drug delivery, medical preparations with inactive ingredients, etc. Strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

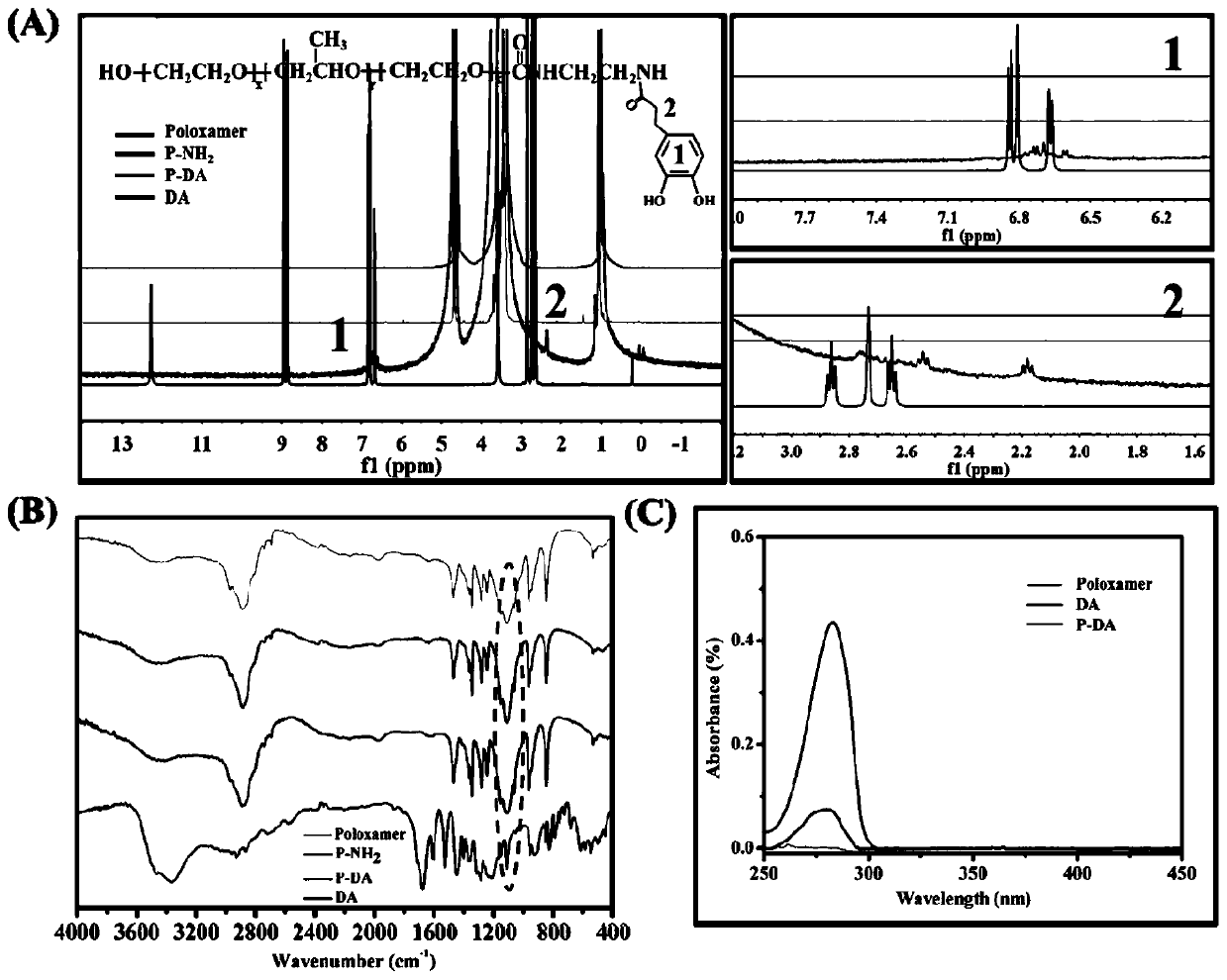

[0041] Example 1 Catechol-terminated polyoxyethylene-polyoxypropylene-polyoxyethylene copolymer

[0042] Weigh 1 part of polyoxyethylene-polyoxypropylene-polyoxyethylene copolymer and dissolve it in dichloromethane, add 5 parts of 4-nitrophenyl chloroformate into the above solution, and add 0.5 parts after it is completely dissolved Triethylamine, after reacting at room temperature for 4 hours, add 5 parts of ethylenediamine to the reaction system, continue stirring at room temperature for 24 hours, remove dichloromethane by rotary evaporation, add 10 parts of distilled water to dissolve the residue, and centrifuge at 5000rpm / min for 5min to remove the precipitate. The supernatant was dialyzed against deionized water with a dialysis membrane (molecular weight cut-off of 3500Da) for 3-5 days, and then freeze-dried for 24 hours to obtain an amino-terminated polyoxyethylene-polyoxypropylene-polyoxyethylene copolymer;

[0043] Weigh 1 part of polyoxyethylene-polyoxypropylene-polyo...

Embodiment 2

[0048] Example 2 Bioadhesive Determination

[0049] Catechol-terminated polyoxyethylene-polyoxypropylene-polyoxyethylene copolymers are dispersed in cold water, left overnight to dissolve completely, and a solution with a concentration of 20% is prepared, and gelled in a water bath at 37°C for 30 minutes to prepare Bioadhesive gel. Maintaining a temperature of 37°C, the bioadhesive gel was placed between two POM (polyoxymethylene or polyoxymethylene) discs, and the adhesion force of the bioadhesive thermosensitive gel was measured using a universal tester.

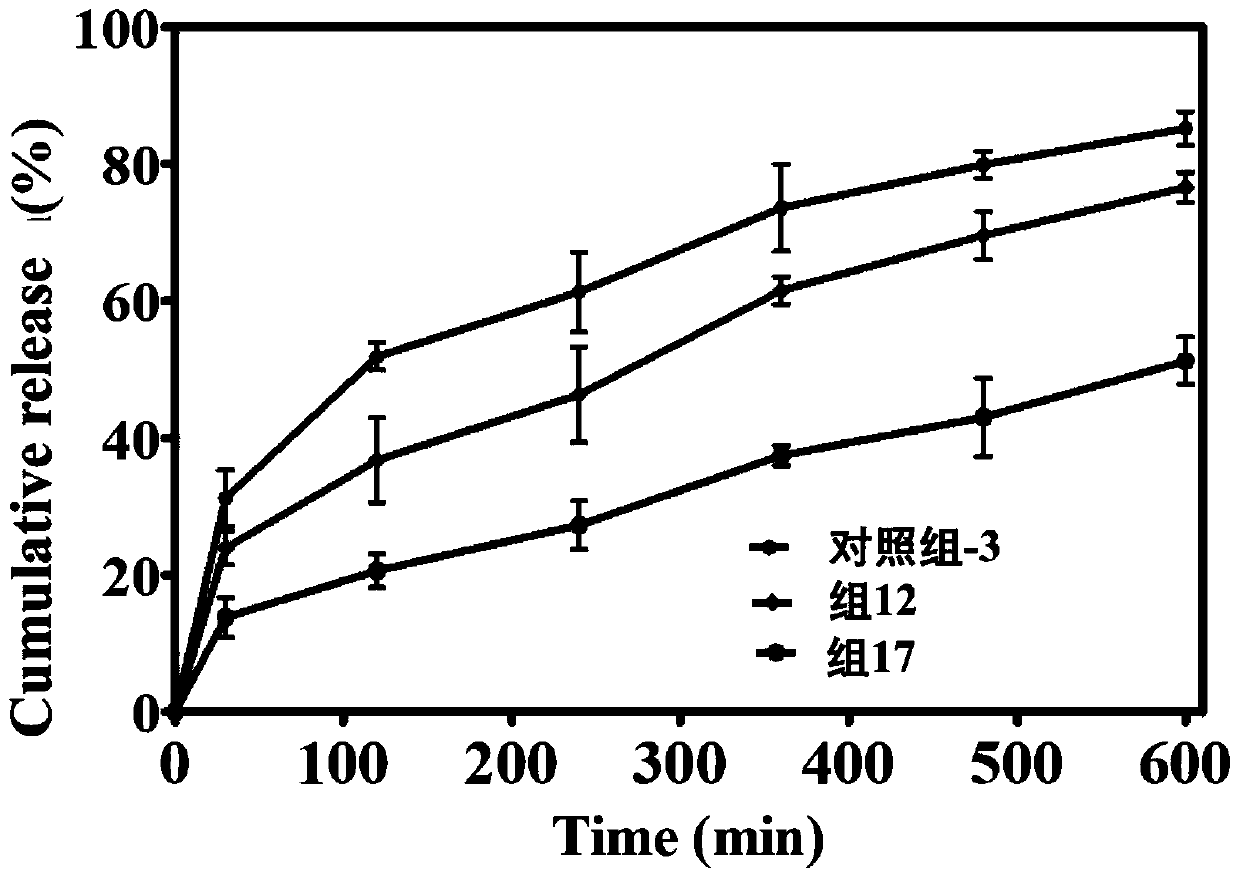

[0050] As can be seen from Table 1, the polyoxyethylene-polyoxypropylene-polyoxyethylene copolymer of catechol-terminated polyoxyethylene-polyoxypropylene-polyoxyethylene copolymer compared with the polyoxyethylene-polyoxypropylene-polyoxyethylene in the control group-1 or the control group-2 The copolymer has stronger bioadhesive force, and with the increase of the caffeic acid percentage in the polymer, the bioadhesive ...

Embodiment 3

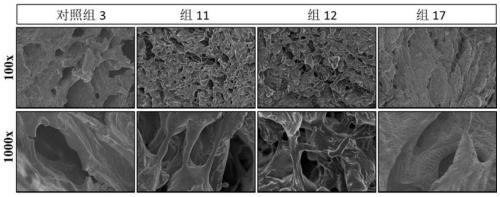

[0051] Embodiment 3 Determination of gelation temperature

[0052] Catechol-terminated polyoxyethylene-polyoxypropylene-polyoxyethylene copolymers are dispersed in cold water, left overnight to dissolve completely, and a solution with a concentration of 20% is prepared, put into a vial, and incubated in a constant temperature oven for 30 minutes. Tilt the vial upside down until the temperature at which no flowable liquid is observed is the gelation temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com