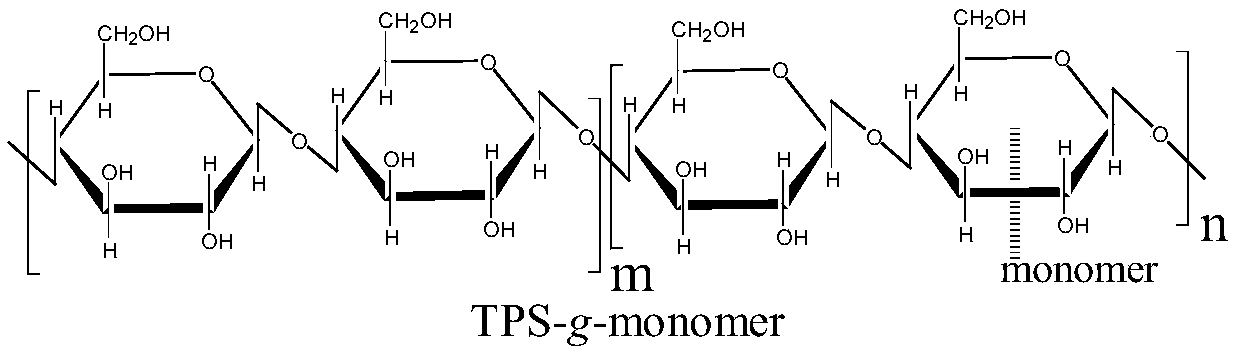

Modified thermoplastic starch and preparation method and application thereof

A thermoplastic starch modification technology, applied in the field of modified thermoplastic starch and its preparation and application, can solve the problems of poor performance stability, poor continuity, weakened hydrogen bonds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The reactive monomer used in the present invention——hydroxyethyl methacrylate (HEMA) is the analytically pure product of Tokyo Chemical Industry Co., Ltd. (TCI), and the initiator——2,5-dimethyl-2,5- Di-tert-butyl peroxide hexane (Double 25) is an analytically pure product of Bailingwei Technology Co., Ltd., which is dispersed in HEMA to prepare a solution with a volume fraction of 5%. The Micro 27 co-rotating twin-screw extruder (screw diameter 27mm, aspect ratio 40) of German Leistritz company was used to mix, plasticize, react and extrude the raw material starch, glycerin and double 25 HEMA solution to produce Graft modified thermoplastic starch (mTPS). The extruder has 11 sections from the feed port to the die, numbered 1-11, wherein the first section only plays the role of feeding, and cannot be heated. The temperatures of sections 2-11 of the extruder are respectively: 80°C, 100°C, 120°C, 140°C, 160°C, 180°C, 180°C, 180°C, 180°C and 180°C, and the screw speed is s...

Embodiment 2

[0058]The above-mentioned HEMA, the reactive monomer used in the present invention of double 25--hydroxyethyl methacrylate (HEMA) is the analytically pure product of Tokyo Chemical Industry Co., Ltd. (TCI), initiator--2 , 5-Dimethyl-2,5-di-tert-butylperoxyhexane (Double 25) is an analytically pure product of Bailingwei Technology Co., Ltd., which is dispersed in HEMA to form a volume fraction of 8%. The solution. The Micro 27 co-rotating twin-screw extruder (screw diameter 27mm, aspect ratio 40) of German Leistritz company was used to mix, plasticize, react and extrude the raw material starch, glycerin and double 25 HEMA solution to produce Graft-modified thermoplastic starch. The extruder has 11 sections from the feeding port to the die, numbered 1-11, wherein the first section only plays the role of feeding, and can not be heated. The temperatures of sections 2-11 of the extruder are respectively: 80°C, 100°C, 120°C, 140°C, 160°C, 180°C, 180°C, 180°C, 180°C and 180°C, and ...

Embodiment 3

[0060] The initiator used in the present invention---benzoyl peroxide (BPO) is the product of 98% purity of Bailingwei Technology Co., Ltd. BPO was dispersed in HEMA as described above to make a solution with a volume fraction of 5%. The HEMA (volume fraction 5%) of above-mentioned cornstarch, glycerol and BPO is directly mixed in the Micro27 type co-rotating twin-screw extruder (screw diameter 27mm, aspect ratio 40) of Germany Leistritz company , plasticizing, reacting, and extruding to make graft-modified thermoplastic starch. The extruder has 11 sections from the feed port to the die, numbered 1-11, wherein the first section only plays the role of feeding, and cannot be heated. The temperatures of sections 2-11 of the extruder are respectively: 60°C, 80°C, 120°C, 140°C, 140°C, 140°C, 140°C, 140°C, 140°C and 140°C, and the screw speed is set at 100 rpm. The K-CL-24-KT20 loss-in-weight feeder of Swiss K-Tron Company was used to feed cornstarch to the first section of the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com