Application of NiPS3 nanosheet in sodium ion battery and sodium ion battery

A sodium ion battery and nanosheet technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems affecting the insertion and extraction of sodium ions, and reduce the charge and discharge capacity, and achieve high rate performance, high electric capacity, and realization of The effect of fast charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

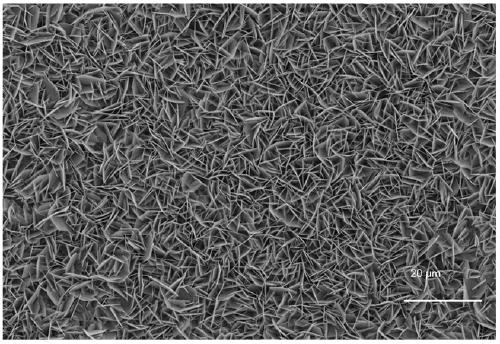

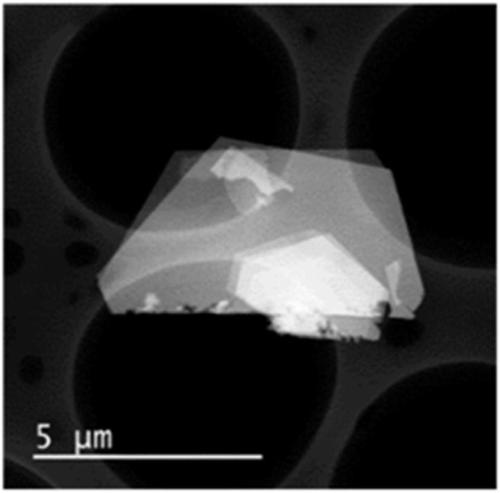

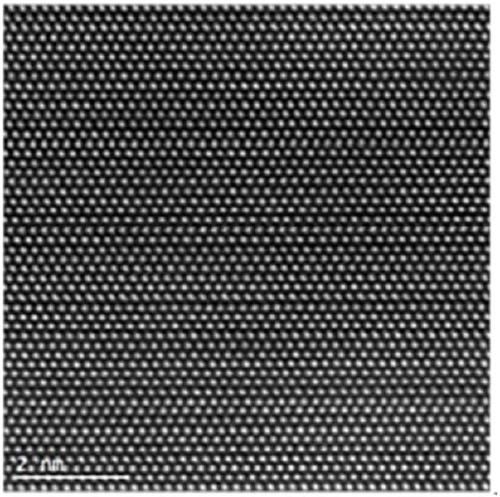

[0056] This embodiment provides a NiPS 3 The preparation method of the nanosheet includes the following steps:

[0057] (1) Immerse clean FTO glass (size 2cm×2cm) into 30mL 2.5mM Ni(NO 3 ) 2 ·6H 2 O and 5mM hexamethylenetetramine (HMT) mixed solution, and then placed in a 50mL PTFE reactor heated to 100 ℃ for 10 hours, after the reaction is over, take out the sample, wash and dry at 60 ℃ for use , Get Ni(OH) evenly distributed on the surface of FTO glass 2 Nanosheets;

[0058] (2) Ni(OH) grown on the surface of FTO glass 2 Nanosheets and red phosphorus / sulfur mixed powder are placed on the sealed ends of the two quartz sleeves, and Ni(OH) 2 Nanosheets are placed in the downstream heating zone (T2 temperature zone) of the dual temperature zone tube furnace, and the red phosphorus / sulfur mixed powder is placed in the upstream heating zone (T1 temperature zone), and the tube furnace system is vacuumed with a mechanical pump. Subsequently, high-purity argon gas 25sccm was introduced, a...

Embodiment 2

[0062] This embodiment provides a NiPS 3 The preparation method of the nanosheet includes the following steps:

[0063] (1) Immerse clean FTO glass in 30mL 2.5mM Ni(NO 3 ) 2 ·6H 2 O and 5mM hexamethylenetetramine (HMT) mixed solution, and then placed in a 50mL polytetrafluoroethylene reactor heated to 100 ℃ for 10 hours, after the reaction is over, take out the sample, wash and dry at 60 ℃ for use , Get Ni(OH) evenly distributed on the surface of FTO glass 2 Nanosheets;

[0064] (2) Ni(OH) grown on the surface of FTO glass 2 Nanosheets and red phosphorus / sulfur mixed powder are placed on the sealed ends of the two quartz sleeves, and Ni(OH) 2 Nanosheets are placed in the downstream heating zone (T2 temperature zone) of the dual temperature zone tube furnace, and the red phosphorus / sulfur mixed powder is placed in the upstream heating zone (T1 temperature zone), and the tube furnace system is vacuumed with a mechanical pump. Subsequently, 30 sccm of high-purity argon gas was introdu...

Embodiment 3

[0067] This embodiment provides a NiPS 3 The preparation method of the nanosheet includes the following steps:

[0068] (1) Immerse clean FTO glass in 30mL 2.5mM Ni(NO 3 ) 2 ·6H 2 O and 5mM hexamethylenetetramine (HMT) mixed solution, and then placed in a 50mL polytetrafluoroethylene reactor heated to 100 ℃ for 10 hours, after the reaction is over, take out the sample, wash and dry at 60 ℃ for use , Get Ni(OH) evenly distributed on the surface of FTO glass 2 Nanosheets;

[0069] (2) Ni(OH) grown on the surface of FTO glass 2 Nanosheets and red phosphorus / sulfur mixed powder are placed on the sealed ends of the two quartz sleeves, and Ni(OH) 2 Nanosheets are placed in the downstream heating zone (T2 temperature zone) of the dual temperature zone tube furnace, and the red phosphorus / sulfur mixed powder is placed in the upstream heating zone (T1 temperature zone), and the tube furnace system is vacuumed with a mechanical pump. Then, 30 sccm of high-purity argon gas was introduced, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com