Low-cost hard alloy milling cutter

A cemented carbide, low-cost technology, used in milling cutters, cutters for milling machines, milling machine equipment, etc., can solve problems such as the reduction of the joint area between the tool holder and the blade, and the inability of the welding strength to meet the shear force requirements of the milling cutter. , to reduce production costs, increase shear resistance, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

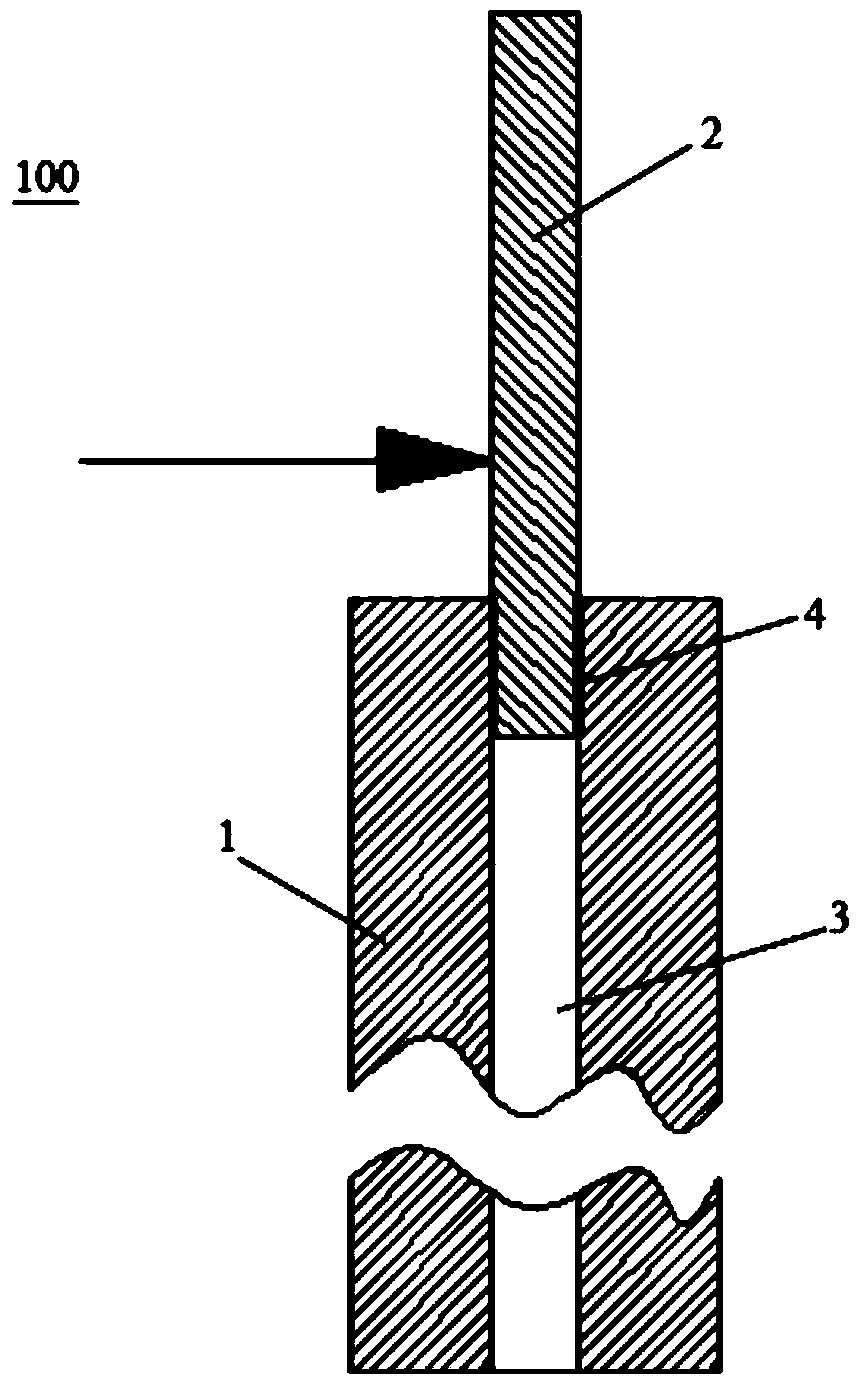

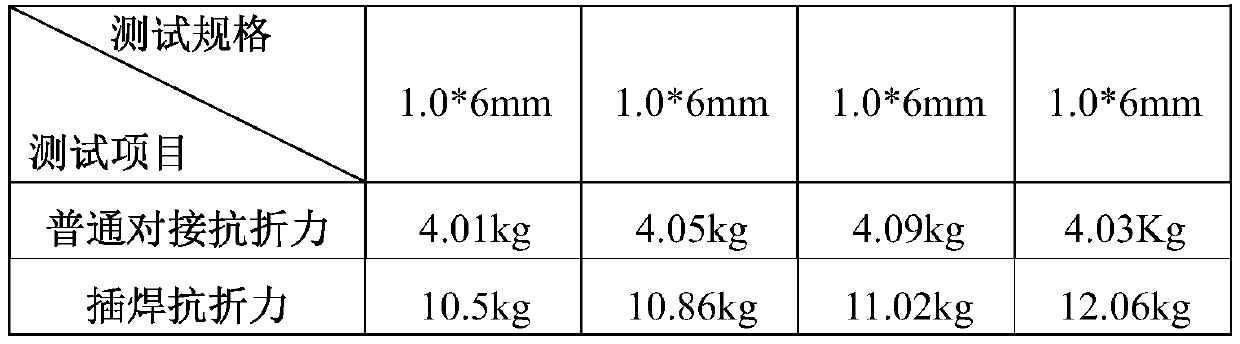

[0018] Please refer to figure 1 , the present embodiment is a low-cost cemented carbide milling cutter 100, which includes a handle 1, a blade 2, the center of the handle 1 is provided with a through hole 3 that penetrates up and down, and the lower end of the blade 2 is inserted into the through hole 3 and Soldered on the inner wall surface of the through hole 3 by silver-copper solder 4 . The silver-copper solder 4 is silver-copper powder and flux.

[0019] The diameter of the handle 1 is 3.075-3.275 mm.

[0020] The diameter of the through hole 3 is 0.6-2.5 mm, preferably 1.0 mm, 1.1 mm, 1.2 mm, 1.5 mm or 2.0 mm.

[0021] In this embodiment, a through hole 3 is set in the handle 1, and then the lower end of the blade 2 is inserted into the through hole 3 and welded together with the inner wall surface of the through hole 3 by silver-copper powder and flux, when the handle 1 and After the entire blade 2 is put into a high temperature of 680-720° C., under the action of fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com