Spherical high-chromium high-copper alloy powder for 3D printing and preparation method of alloy powder

A 3D printing and copper alloy technology, applied in the field of spherical high-chromium copper alloy powder for 3D printing and its preparation, can solve the problems of the introduction of inclusions and the macrosegregation of powder in the process of spherical high-chromium copper alloy powder, so as to reduce the risk of clogging , The droplet size is small, and the effect of preventing secondary oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

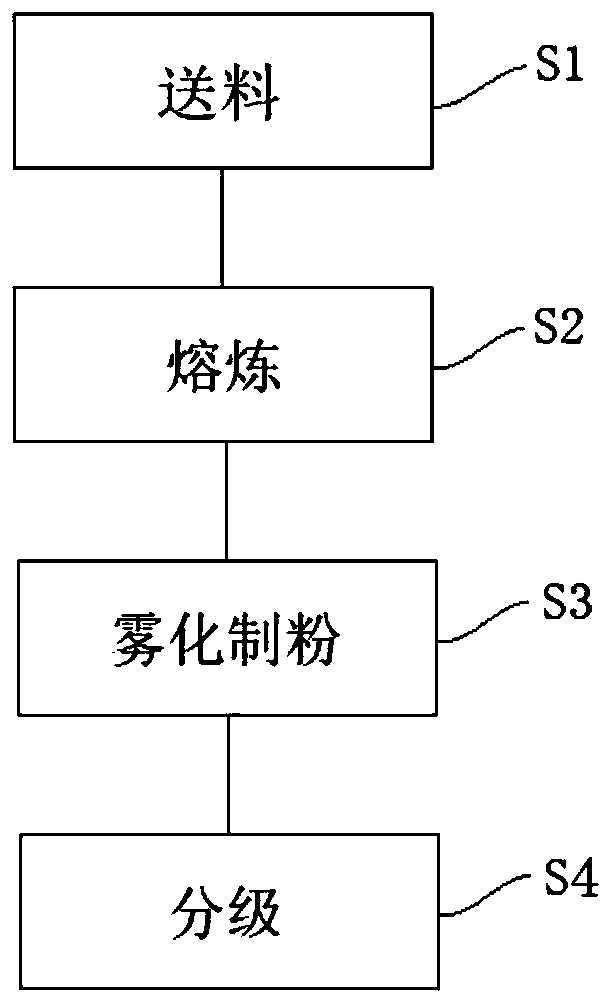

[0052] The invention discloses a method for preparing spherical high-chromium copper alloy powder for 3D printing. figure 1 It is a schematic flow chart of the preparation method of the spherical high-chromium copper alloy powder for 3D printing provided in the embodiments of the present invention, such as figure 1 As shown, the preparation method mainly includes the following steps:

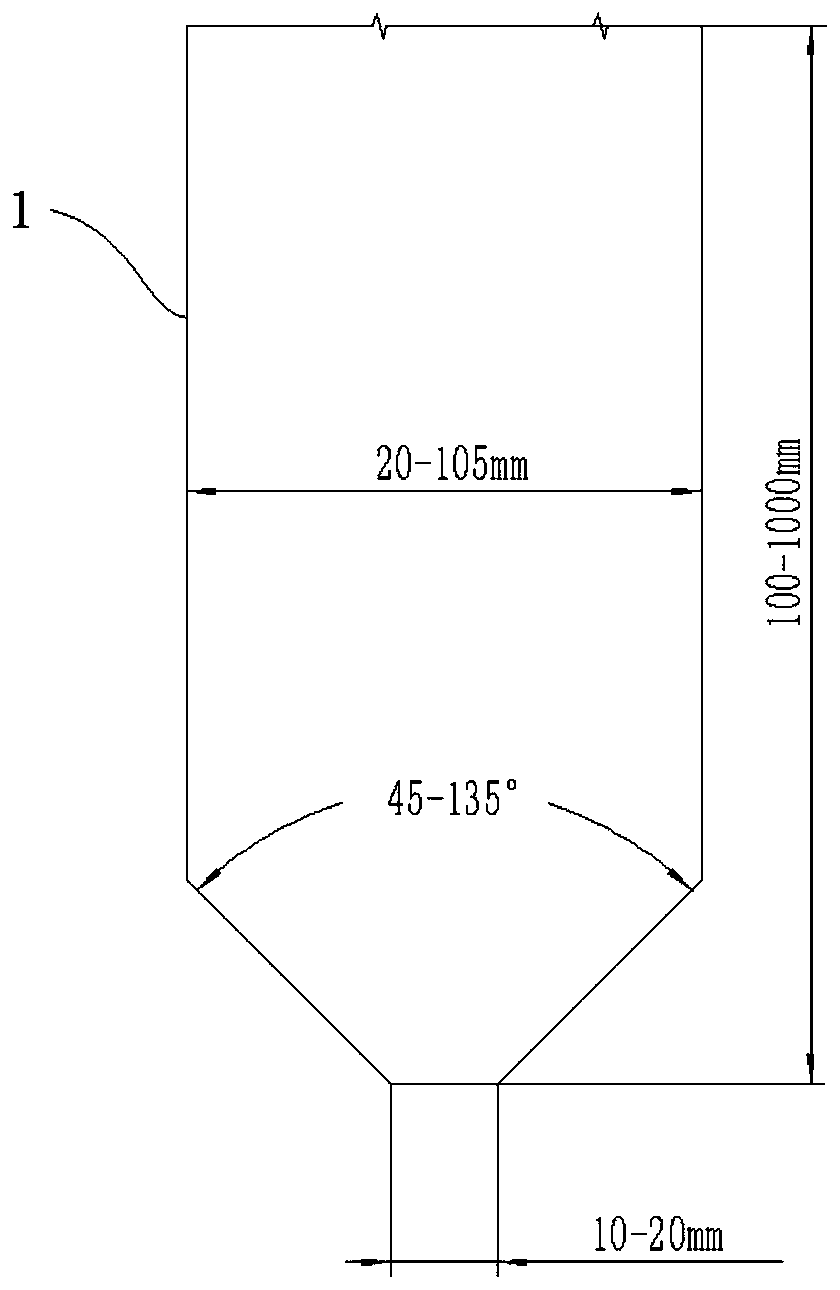

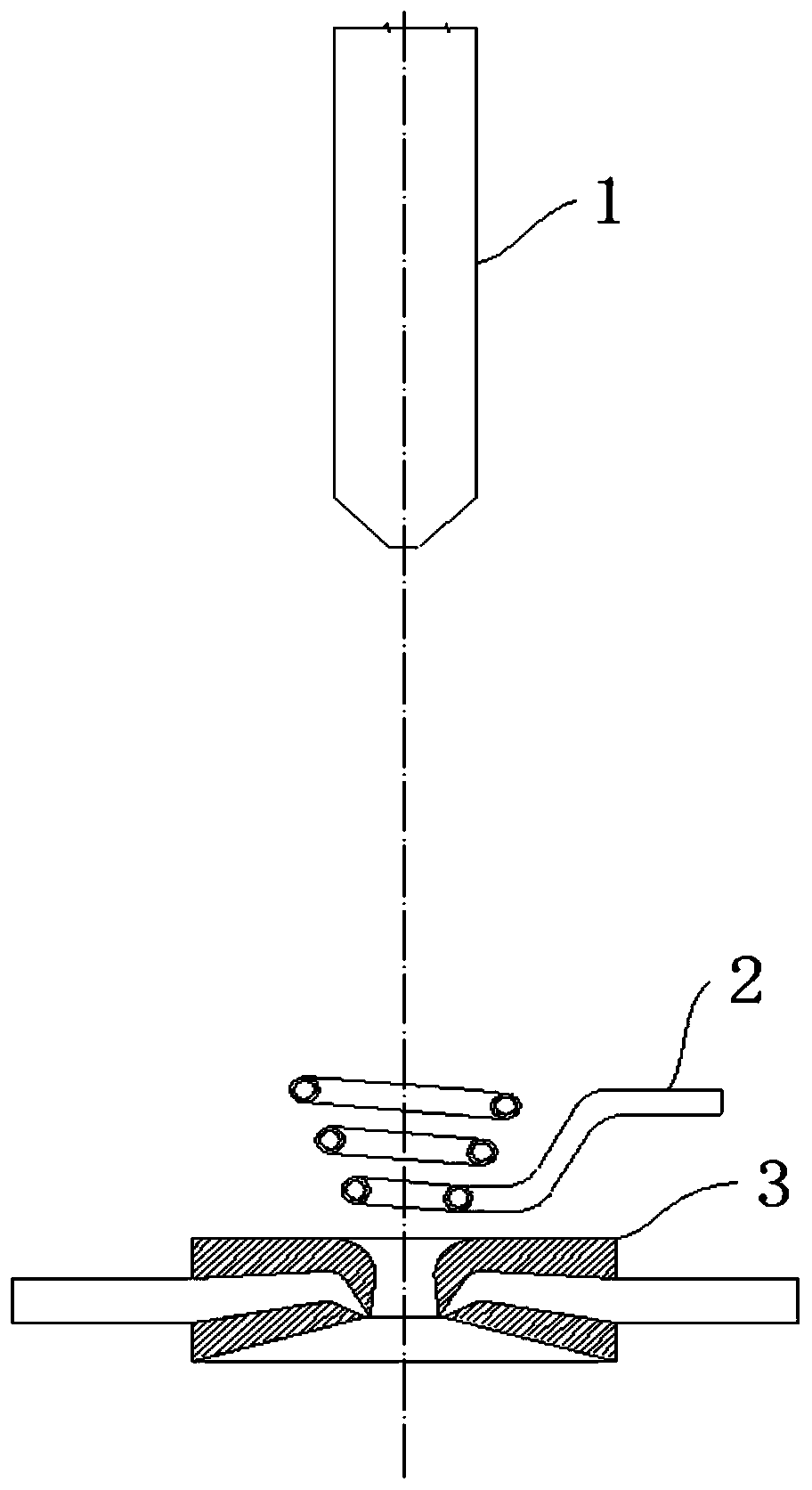

[0053] In step S0, the copper-chromium alloy is prepared into a copper-chromium alloy rod as an induction electrode by using a vacuum induction casting process, and then the head is processed to figure 2 Dimensions shown, form a bar with a conical tip; or use powder compaction to prepare a bar with a conical tip; wherein, the chromium content in the bar is 2 to 50% by mass percentage; The diameter is 20-105mm, and the length is 100-1000mm; the cone angle at the top of the bar is 45-135°, and the diameter of the cone tip at the top of the bar is 10-20mm.

[0054] It should be noted that the me...

Embodiment 1

[0073] Step S0, processing the copper-chromium alloy rod with a chromium content of 40% (mass ratio) by vacuum induction melting into an electrode with a diameter of 40 mm, a length of 600 mm, a taper angle at one end of the bar stock is 90°, and a tip diameter at one end of the taper angle is 15 mm. Bar stock, and the bar stock is installed on the feeding device.

[0074] Step S1, vacuumize the whole device, the degree of vacuum is 10 -1 Pa, and filled with argon gas protection, the pressure of the argon gas protection environment is -0.005 ~ 0.005Mpa; the electrode bar moves from the first limit position to the second limit position at a rotation speed of 140r / min and a descending speed of 1000mm / min bit position.

[0075] Step S2, turn on the exhaust fan and exhaust valve to maintain a slight negative pressure inside the system, and at the same time, fill the upper chamber of the atomizer with gas to keep the pressure difference between the upper and lower chambers at 0.03...

Embodiment 2

[0080] The preparation method in embodiment 2 is the same as the preparation method in embodiment 1, and the difference is that the preparation process parameters are different, specifically as follows:

[0081] In step S0, the rod stock is an electrode rod with a diameter of 105 mm and a length of 1000 mm processed from a copper-chromium alloy with a chromium content of 50% (mass ratio). ;

[0082] In step S1, the electrode rod moves from the first limit position to the second limit position at a rotation speed of 40r / min and a descending speed of 2000mm / min;

[0083] In step S2, the power of the exhaust fan is 22Kw, the wind pressure is 10000Pa, and the air volume is 1000m 3 / h, the pressure of the protective gas pipeline leading into the upper cavity of the nozzle is 0.1Mpa, and the flow rate is 20m 3 / h; the high-frequency heating power supply is 30Kw, the frequency is 250KHz, and the copper-chromium alloy electrode rod is heated by induction with a conical coil. The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Upper mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com