Titanium or titanium alloy spherical powder with rare earth oxide distributed on surface and preparation method for titanium or titanium alloy spherical powder

A technology of rare earth oxide and spherical powder, which is applied in the field of metal powder materials to achieve the effect of refining microstructure and mechanical properties, improving fluidity and increasing proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

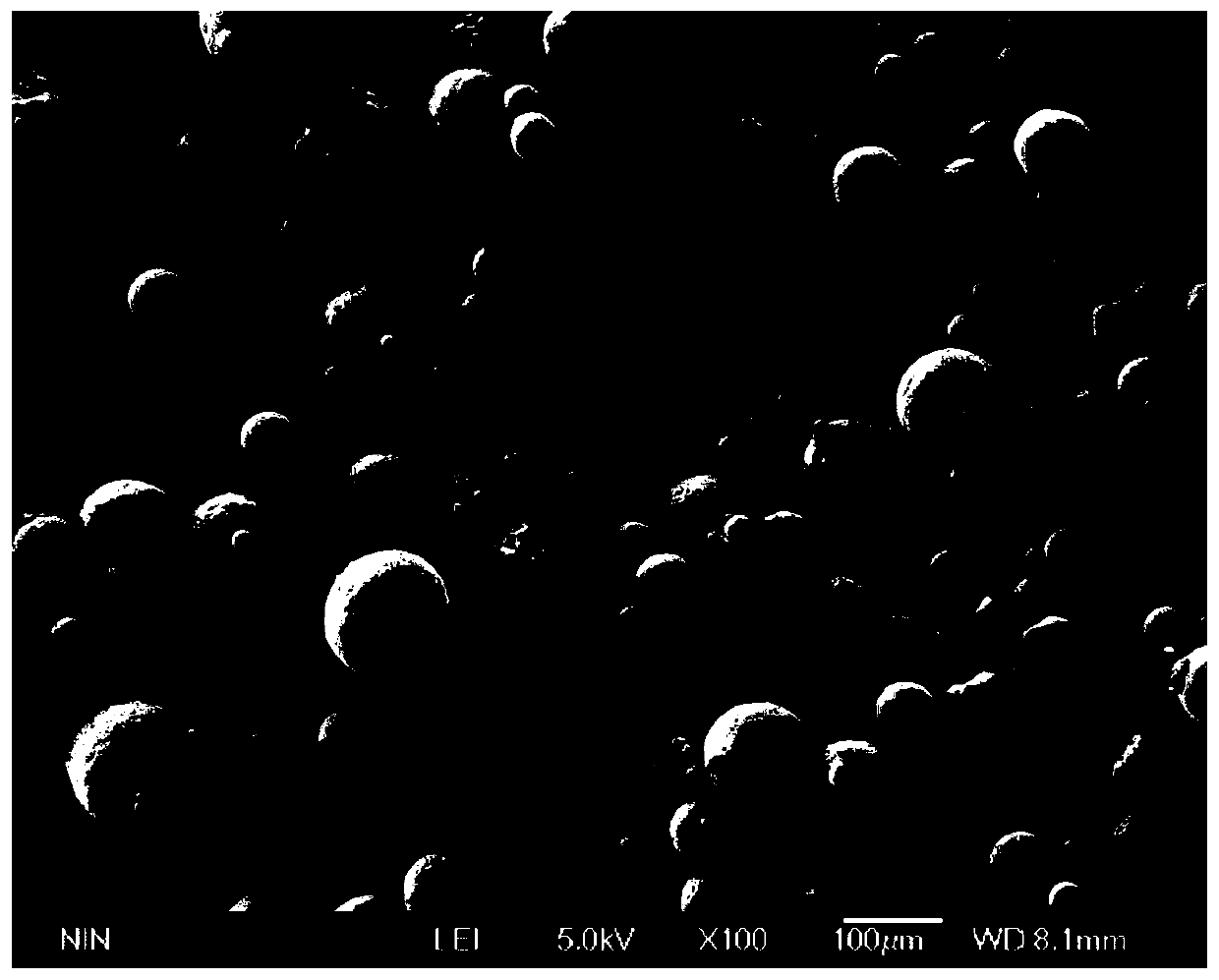

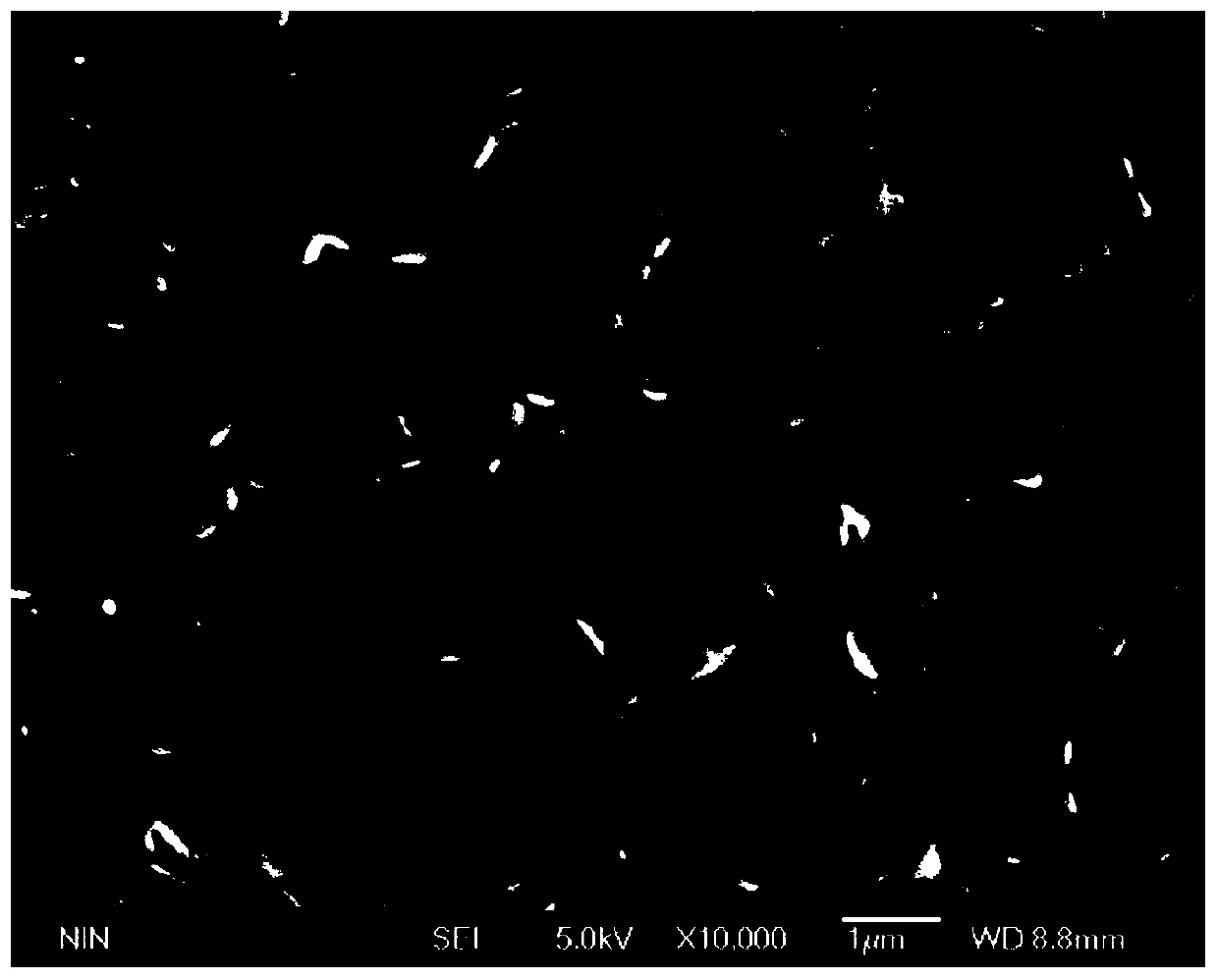

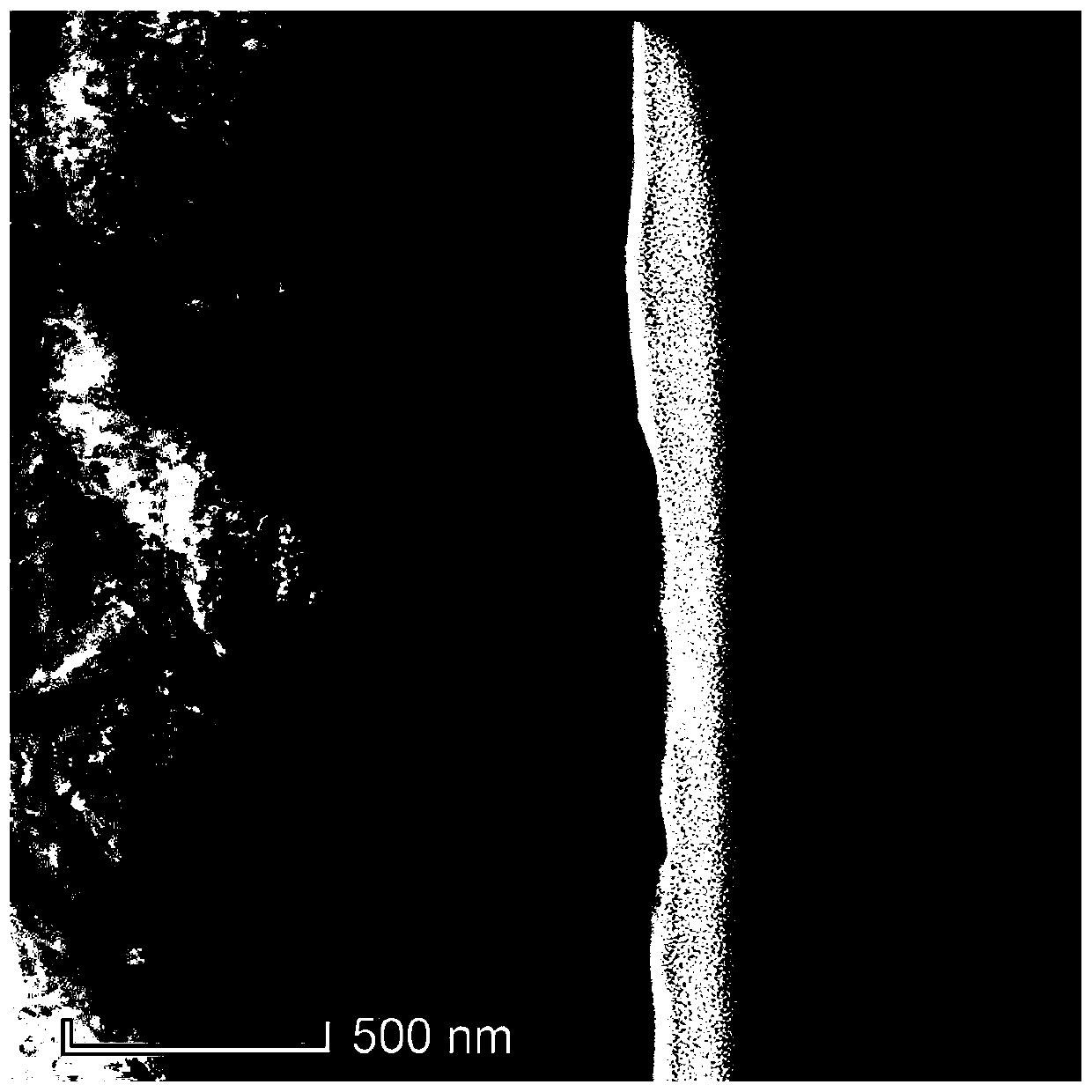

[0030] In this embodiment, the TC4 titanium alloy spherical powder surface is diffusely distributed with flake Y with an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Y 0.32%, O 0.12%, Al 5.95%, V 4.20%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0031] The surface is diffusely distributed with flake Y 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0032] Step 1, cleaning the rare earth metal Y of 0.06kg and the TC4 titanium alloy of 19.94kg respectively, and then mixing them to obtain mixed raw materials;

[0033] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomization equipment, and th...

Embodiment 2

[0056] In this embodiment, the TC4 titanium alloy spherical powder surface is diffusely distributed with flake Nd with an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Nd 0.12%, O0.08%, Al 6.20%, V 4.16%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0057] The surface is diffusely distributed with flake Nd 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0058] Step 1, the rare earth metal Nd of 0.02kg and the TC4 titanium alloy of 19.98kg are respectively cleaned, and then mixed to obtain mixed raw materials;

[0059] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomization equipment, and th...

Embodiment 3

[0064] In this embodiment, the TC4 titanium alloy spherical powder surface is dispersedly distributed with flake Gd having an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Gd 0.29%, O 0.10%, Al 5.76%, V 3.84%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0065] The surface is diffusely distributed with flake Gd 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0066] Step 1, the rare earth metal Gd of 0.06kg and the TC4 titanium alloy of 19.94kg are respectively cleaned and processed, and then mixed to obtain mixed raw materials;

[0067] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com