Automobile brake pad adopting carbon fiber reinforced composite material

A technology of reinforced composite materials and brake pads, which is applied in the field of automobile brake pads, can solve problems such as poor thermal conductivity, insufficient brake pad strength, and non-wear resistance, so as to improve rigidity and toughness, improve wear resistance and practicability, and improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

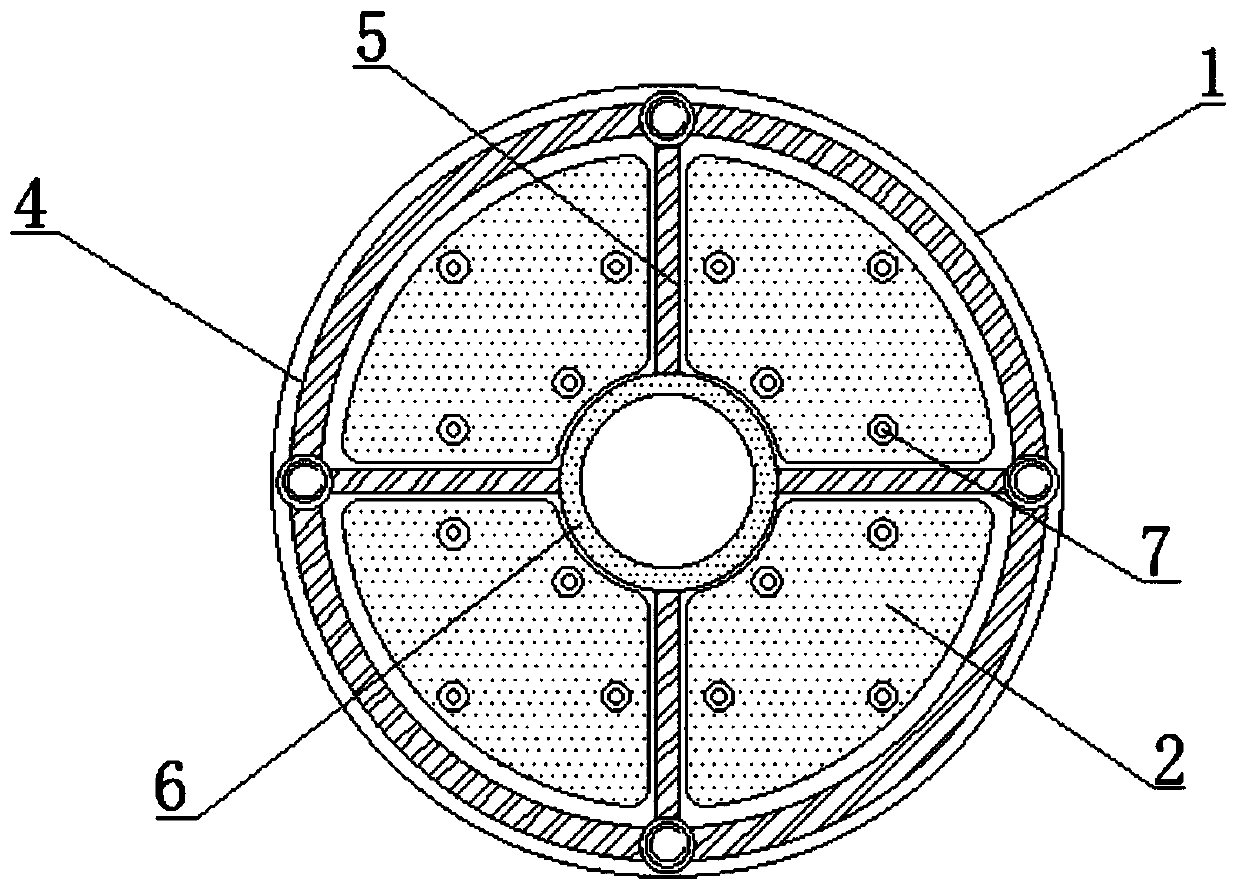

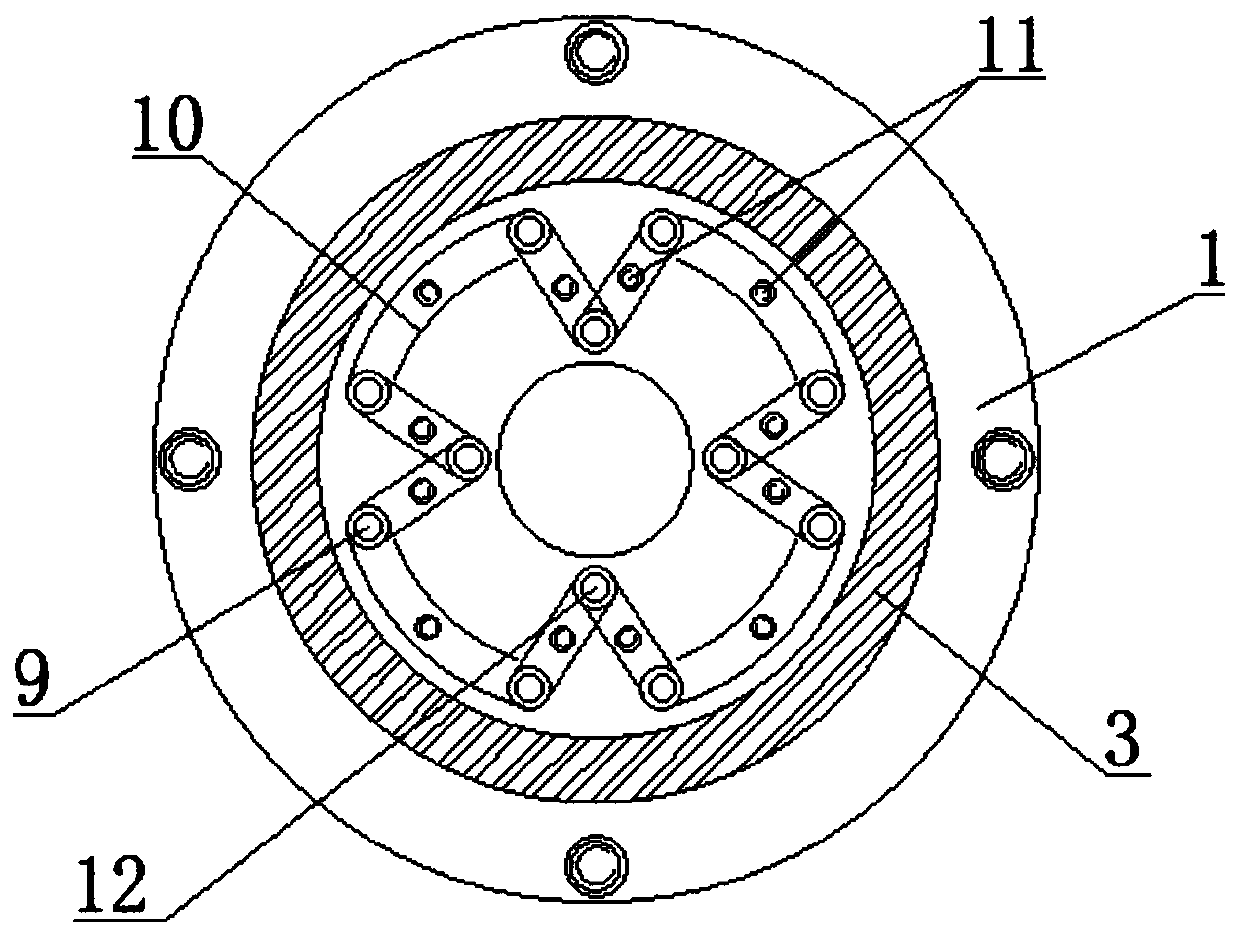

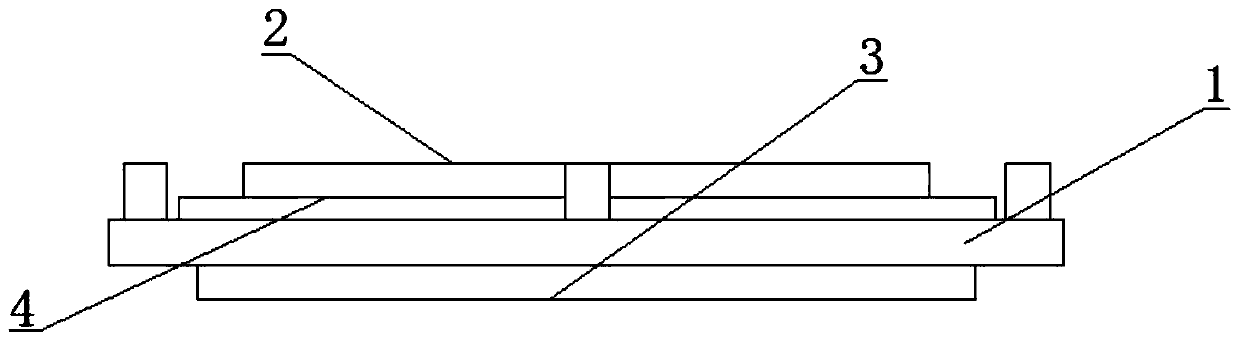

[0026] An automobile brake pad that adopts carbon fiber reinforced composite material, including a brake pad base material 1 and a friction pad 2, and the friction pad 2 includes the following constituent raw materials in parts by weight:

[0027] 25 parts of carbon fiber modified phenolic resin, 20 parts of carbon fiber modified PC / ABS alloy, 18 parts of glass fiber modified diphenyl ether formaldehyde resin, 15 parts of carbon fiber, 15 parts of polyamide fiber, 12 parts of polyester fiber, 10 parts of glass fabric , 10 parts of alloy fiber, 8 parts of nano-scale silicon nitride, 6 parts of silicon carbide fiber, 13 parts of spidroin fiber, 6 parts of toughened alumina fiber, 8 parts of nano-scale calcium carbonate powder, γ-FeO(OH), 8 parts of mixed whiskers of FeCO3 and CaTiO3.

[0028] Further, the alloy fiber includes the following percentages of constituent raw materials:

[0029] Iron 70wt%, aluminum 5wt%, titanium 5wt%, manganese 4wt%, chromium 3wt%, tungsten 3wt%, m...

Embodiment 2

[0032] An automobile brake pad that adopts carbon fiber reinforced composite material, including a brake pad base material 1 and a friction pad 2, and the friction pad 2 includes the following constituent raw materials in parts by weight:

[0033] 20 parts of carbon fiber modified phenolic resin, 15 parts of carbon fiber modified PC / ABS alloy, 15 parts of glass fiber modified diphenyl ether formaldehyde resin, 10 parts of carbon fiber, 8 parts of polyamide fiber, 8 parts of polyester fiber, 6 parts of glass fabric , 5 parts of alloy fiber, 3 parts of nano-scale silicon nitride, 3 parts of silicon carbide fiber, 5 parts of spidroin fiber, 2 parts of toughened alumina fiber, 4 parts of nano-scale calcium carbonate powder, γ-FeO(OH), Mixed whiskers of FeCO3 and CaTiO3 3 parts.

[0034] Further, the alloy fiber includes the following percentages of constituent raw materials:

[0035] Iron 60wt%, aluminum 8wt%, titanium 10wt%, manganese 7wt%, chromium 5wt%, tungsten 5wt%, molybden...

Embodiment 3

[0038] An automobile brake pad that adopts carbon fiber reinforced composite material, including a brake pad base material 1 and a friction pad 2, and the friction pad 2 includes the following constituent raw materials in parts by weight:

[0039] 25 parts of carbon fiber modified phenolic resin, 15 parts of carbon fiber modified PC / ABS alloy, 18 parts of glass fiber modified diphenyl ether formaldehyde resin, 10 parts of carbon fiber, 15 parts of polyamide fiber, 8 parts of polyester fiber, 10 parts of glass fabric , 5 parts of alloy fiber, 8 parts of nano-scale silicon nitride, 3 parts of silicon carbide fiber, 13 parts of spidroin fiber, 2 parts of toughened alumina fiber, 8 parts of nano-scale calcium carbonate powder, γ-FeO(OH), Mixed whiskers of FeCO3 and CaTiO3 3 parts.

[0040] Further, the alloy fiber includes the following percentages of constituent raw materials:

[0041] Iron 70wt%, aluminum 5wt%, titanium 5wt%, manganese 5wt%, chromium 5wt%, tungsten 5wt%, molybd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com