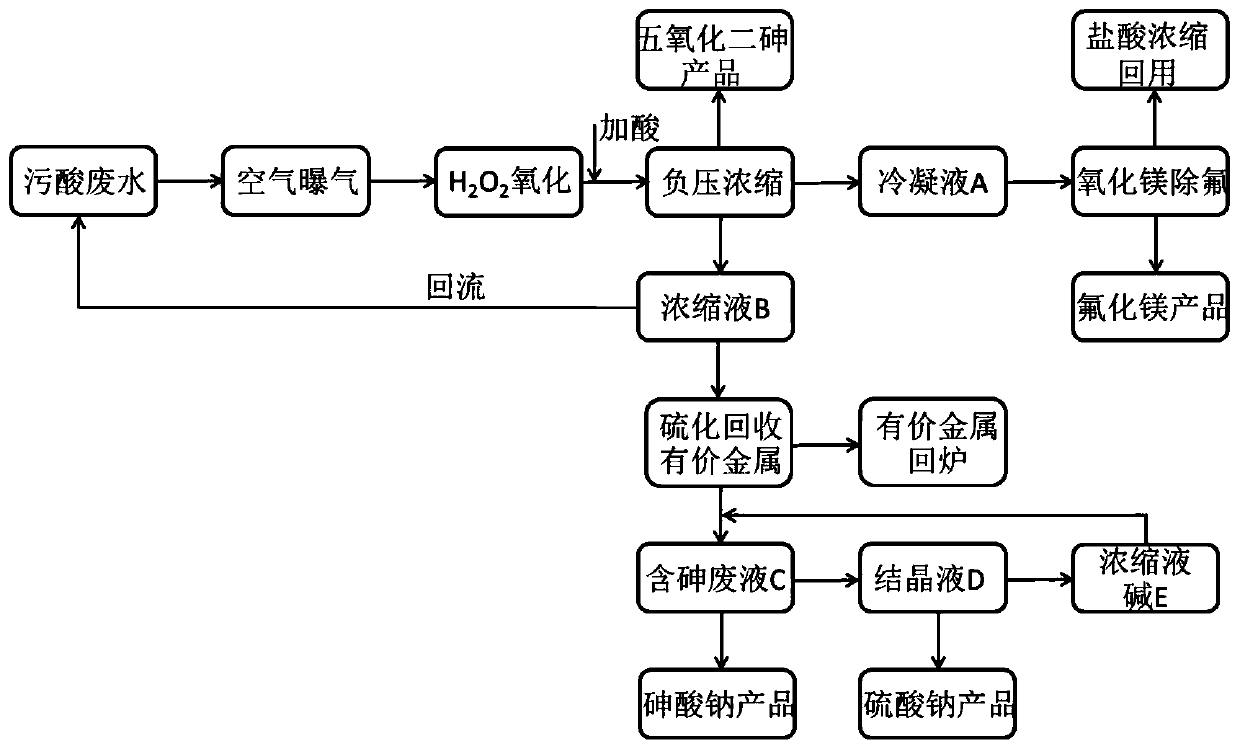

Method for resource utilization of waste sulfuric acid wastewater produced in copper smelting and acquisition of arsenic-containing products

A technology for sewage acid wastewater and copper smelting, which is applied in metallurgical wastewater treatment, chemical instruments and methods, alkali metal sulfite/sulfite, etc. and other problems, to achieve the effects of high fluorine and chlorine removal rate, high cost and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In this embodiment, the sulfuric acid waste water discharged from the sulfuric acid workshop of a copper smelter in Hubei is used as the treatment object. The lead content is 650mg / L, the lead content is 30mg / L, the cadmium content is 124mg / L, the zinc content is 287mg / L, and the pH is 1.5.

[0058] A method for utilizing and obtaining arsenic-containing products from sulfuric acid waste water resources in the copper smelting industry described in this embodiment, the steps are as follows:

[0059] (1) Oxidation stage: Take 1L of polluted acid wastewater, place it in a polluted acid storage tank for air aeration, the gas-liquid ratio is 1.0, the air aeration time is 10h, and the dissolved oxygen in the solution after aeration is 9.1mg / L;

[0060] The polluted acid wastewater after aeration flows into the hydrogen peroxide reaction tank, and 8wt% hydrogen peroxide is added in two sections at the bottom of the hydrogen peroxide reaction tank. The amount of hydrogen peroxi...

Embodiment 2

[0085] In this embodiment, the sulfuric acid waste water discharged from the sulfuric acid workshop of a copper smelter in Gansu is used as the treatment object. The lead content is 200mg / L, the lead content is 60mg / L, the cadmium content is 50mg / L, the zinc content is 1407mg / L, and the pH is 0.7.

[0086] A method for utilizing and obtaining arsenic-containing products from sulfuric acid waste water resources in the copper smelting industry described in this embodiment, the steps are as follows:

[0087] (1) Oxidation stage: take 1L of polluted acid wastewater, place it in a polluted acid storage tank for air aeration, the gas-liquid ratio is 1.0, the air aeration time is 8 hours, and the dissolved oxygen in the solution after aeration is 8.7mg / L;

[0088] The polluted acid wastewater after aeration flows into the hydrogen peroxide reaction tank, and 10wt% hydrogen peroxide is added in two sections at the bottom of the hydrogen peroxide reaction tank. The amount of hydrogen p...

Embodiment 3

[0103] In this embodiment, the sulfuric acid polluted acid wastewater discharged from the sulfuric acid workshop of a copper smelter in Anhui is used as the treatment object. The lead content is 350mg / L, the lead content is 80mg / L, the cadmium content is 30mg / L, the zinc content is 430mg / L, and the pH is 0.6.

[0104] A method for utilizing and obtaining arsenic-containing products from sulfuric acid waste water resources in the copper smelting industry described in this embodiment, the steps are as follows:

[0105] (1) In the oxidation stage, take 1L of polluted acid wastewater, place it in a dirty acid storage tank for air aeration, the gas-liquid ratio is 1.0, the air aeration time is 15 hours, and the dissolved oxygen in the solution after aeration is 9.4mg / L;

[0106] The polluted acid wastewater after aeration flows into the hydrogen peroxide reaction tank, and 8wt% hydrogen peroxide is added in two sections at the bottom of the hydrogen peroxide reaction tank. The amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com