Method for testing dynamics and interface behaviors of molten slag dissolved solid oxide based on hot filament method

A technology of solid oxides and testing methods, which is applied in the direction of material analysis, measuring devices, and scientific instruments through optical means. It can solve problems such as poor light transmission, low cooling speed, and complicated operations, and achieve low equipment costs and slag The effect of thin slag film and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

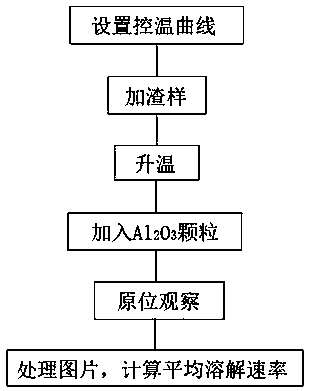

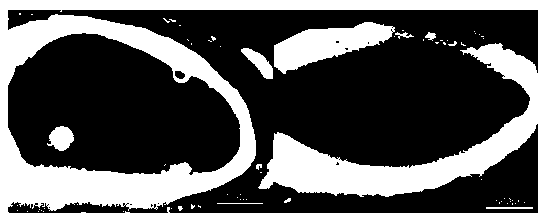

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the following in conjunction with the attached figure 1 -6 and examples (with Al 2 o 3 As an example), the present invention is further described in detail. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the present invention.

[0034] In order to make up for the defects of the rotating cylinder method and the confocal laser scanning microscope method, the general idea of the solution provided by this application is as follows, including the following steps:

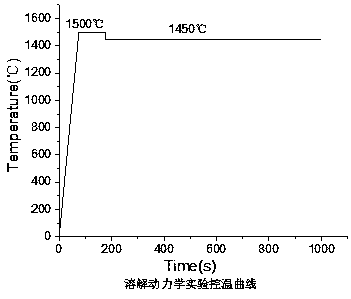

[0035] (1) According to the process requirements, set the experimental temperature control curve of the hot wire method equipment;

[0036] The wire method equipment is a double platinum-rhodium thermocouple, and the temperature control curve that can be set is: the heating rate can be set arbitrarily within the range of 0~30°C / s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com