Nuclear island evaporator reducing cylinder integral forge piece and forging forming method thereof

A technology of integral forgings and evaporators, which is applied in the direction of steam generation, engine components, steam boiler accessories, etc., can solve the problems of increased processing and manufacturing costs, long welding cycle, and high manufacturing costs, so as to improve production efficiency and material utilization. Metal plasticity and forging quality, reducing the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

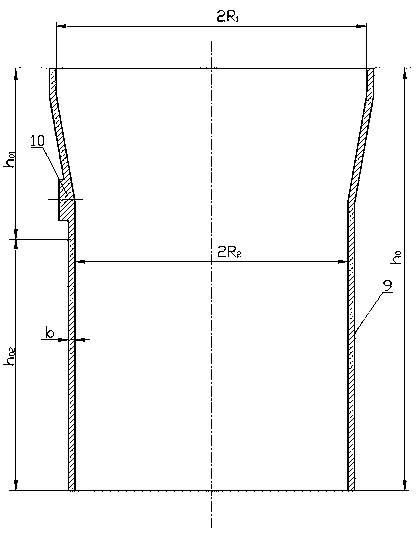

[0026] like figure 1 In the steam generator shown in the integrated finished cylinder of the cone and lower cylinder, the finished cylinder 9 includes a cone cylinder at the top and a cylinder at the bottom, and the cylinder is arranged at the lower end of the cone cylinder; A boss 10 for installing evaporator accessories is provided on the outside. The total cylinder height h of the finished cylinder 9 0 =4750㎜, the wall thickness of the barrel b=65㎜, the height h of the finished tapered tube at the upper part 01 =1400㎜, the inner diameter of the upper mouth of the finished cone tube is 2R 1 =3100㎜, the height of the finished main bobbin located at the lower part of the finished bobbin 9 is h 02 =2150㎜, the inner diameter of the finished main bobbin is 2R 2 =2600㎜. The finished cylinder is made of carbon-manganese low-alloy steel through integral forging to form an integrated structure.

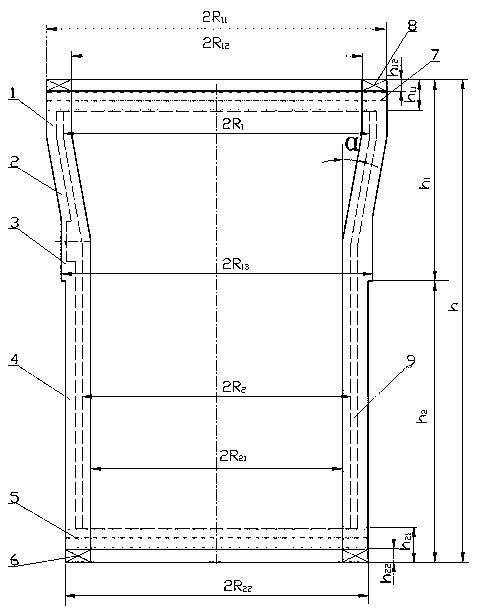

[0027] like figure 2 The whole forging of different-diameter cylinder of nuclear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com