A flocculation-oxidation composite material for improving the water quality of black and odorous water bodies

A black and odorous water body and composite material technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as no turbidity removal method, and achieve an increase in redox potential , reduce chroma, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of flocculation-oxidation composite material, the preparation raw material is bentonite: CaO 2 : LaCl 3 =8:2:1.

[0029] The preparation method is the grinding method: take 0.8g of bentonite, CaO 2 0.2g, LaCl 3 0.1g, namely set bentonite, CaO 2 and LaCl 3 The mass ratio is 8:2:1, and the above raw materials are ground in an agate mortar to make them completely and uniformly mixed to obtain a flocculation-oxidation composite material.

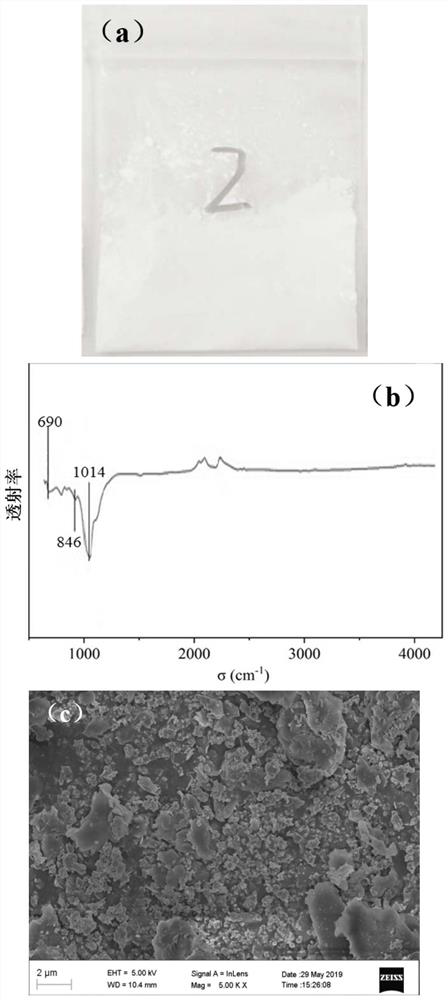

[0030] The as-prepared flocculation-oxidation composites were characterized as figure 2 shown. figure 2 (a) is a photograph of the appearance of the composite material, from which it can be seen that the prepared flocculation-oxidation composite material is light yellow powder. figure 2 (b) is the Fourier transform infrared spectrum of the composite material, which shows that bentonite and CaO 2 It is a single composite material combined by physical force, the ion configuration of bentonite does not change, CaO 2 Ther...

Embodiment 2

[0038] A flocculation-oxidation composite material, the material ratio is bentonite: CaO 2: LaCl 3 =8:2:1.

[0039] The preparation method is sodium alginate embedding method: use deionized water to prepare 100ml containing 3% sodium alginate, 2% bentonite, 0.5% CaO 2 , 0.25% LaCl 3 mixed solution. Then slowly drop the mixed solution into 3% CaCl with a mass concentration of 10ml 2 In the solution, it is fixed into black pellets with a diameter of 3-5 mm. Dilute the pellet in CaCl 2 After cross-linking in solution for 8 hours, filter to keep pellets. The pellets were then dried in an oven at 105 °C for 1 h to constant weight to obtain a composite material.

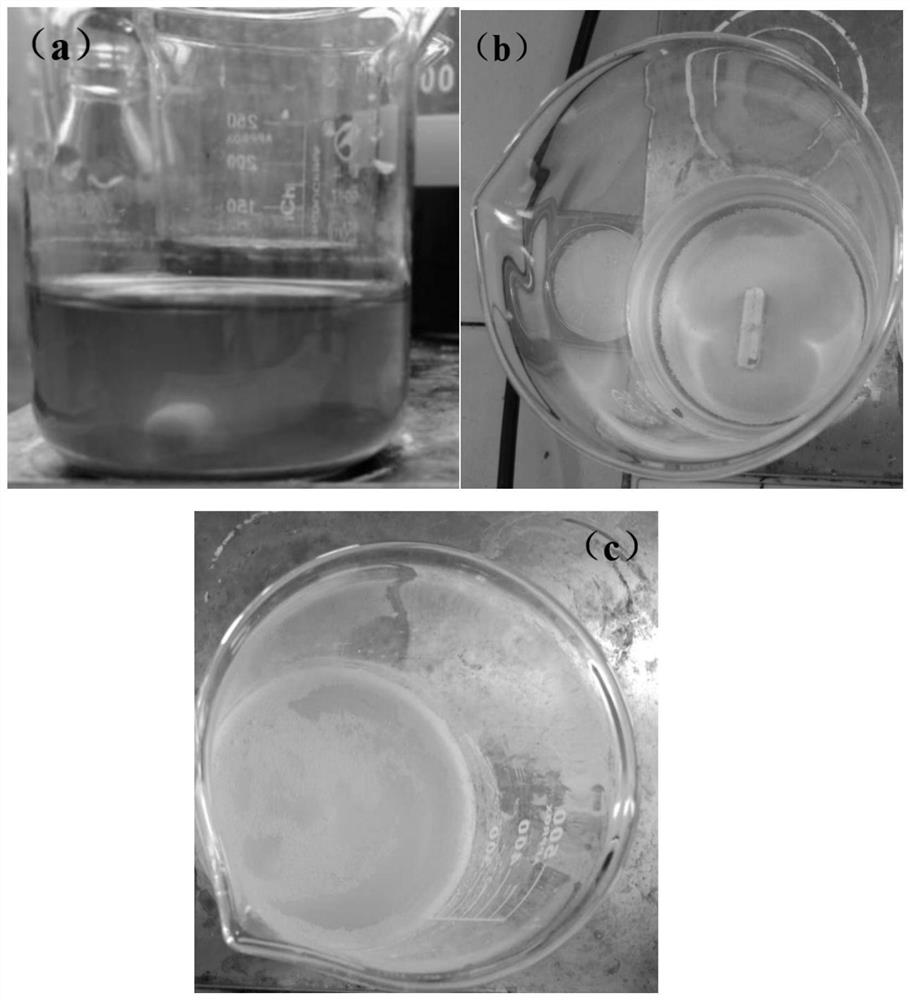

[0040] Mix the obtained composite material with deionized water to configure 100g L -1 Add 2ml of suspension solution to 100ml of black and odorous water, at room temperature at 300r·min -1 Stir at a stirring speed for 3min, then at 50r·min -1 Stir at a stirring speed for 10 minutes and let stand for 30 minutes. ...

Embodiment 3

[0046] A kind of flocculation-oxidation composite material, the preparation raw material is bentonite: CaO 2 : LaCl 3 =8:4:1.

[0047] The preparation method is the grinding method: take 0.8g of bentonite, CaO 2 0.4g, LaCl 3 0.1g, set bentonite, CaO 2 and LaCl 3 The mass ratio is 8:4:1, and the above raw materials are ground in an agate mortar to make them completely and uniformly mixed to obtain a composite material. Mix the obtained composite material with deionized water to configure 100g L -1 Add 2ml of suspension solution to 100ml of black and odorous water, at room temperature at 300r·min -1 Stir at a stirring speed for 3min, then at 50r·min -1 Stir at a stirring speed for 10 minutes and let stand for 30 minutes. Take the supernatant to measure the water quality parameters.

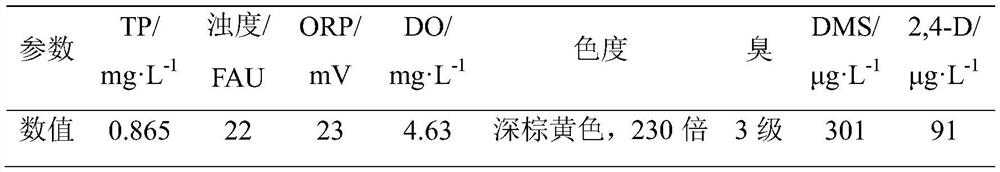

[0048] The effect of the flocculation-oxidation composite material obtained in this embodiment on water quality is shown in Table 4:

[0049] Table 4 Water quality parameters after addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com