A method for separating and purifying lipopeptide surfactin family compounds

A technology for separation and purification of lipopeptides, which is applied to the preparation methods of peptides, chemical instruments and methods, compositions of drilling holes, etc., can solve the problems of cumbersome complexity, high cost, low purity, etc. Low, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares fermented liquid

[0035] The fermentation strain is Bacillus amyloliquefaciens MT45, which is isolated from Moutai Daqu in China and stored in the China General Microorganism Culture Collection and Management Center. Patent pending.

[0036] The composition of LB medium is: yeast powder 5.0g / L, tryptone 10.0g / L, NaCl 10.0g / L.

[0037] Optimal medium composition: sucrose 65g / L, ammonium nitrate 8g / L, peptone 3.73g / L, potassium dihydrogen phosphate 4.08g / L, disodium hydrogen phosphate 10g / L, magnesium sulfate 0.096g / L, calcium chloride 7μM , ferrous sulfate 4 μM, EDTA 4 μM.

[0038] Bacillus amyloliquefaciens MT45 was activated in LB medium, 37°C, 200rpm, cultured for 12h, then inoculated into a 250mL flask containing 50mL optimized medium according to the inoculum size of 2%, and cultured at 30°C, 200rpm for 72h. The fermentation broth was collected, and the supernatant was collected after centrifugation to prepare for the separation and extract...

Embodiment 2

[0039] Embodiment 2 detects the content of protein in the fermented liquid

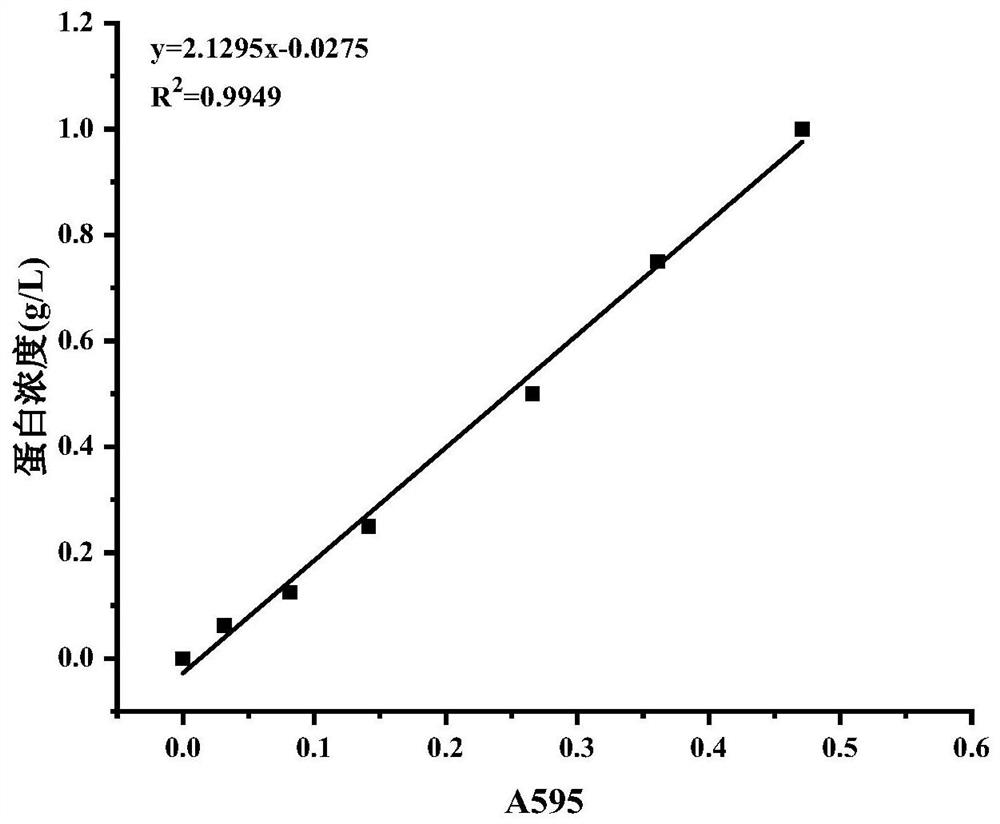

[0040] First establish a standard curve, prepare bovine serum albumin (BSA) to the concentration of 0, 0.0625, 0.125, 0.25, 0.5, 0.75, 1g / L, add Coomassie Brilliant Blue G-250 solution and measure different bovine serum albumin at 595nm The absorbance of the solution.

[0041]After reacting the fermentation broth with Coomassie Brilliant Blue G-250, measure the absorbance at 595nm, establish a standard curve and calculate the protein content in the fermentation broth. like figure 1 As shown, the standard curve is established as: y=2.1295x-0.0275, R 2 = 0.9949. It was detected that the protein content in the initial fermentation liquid was 0.129g / L.

Embodiment 3

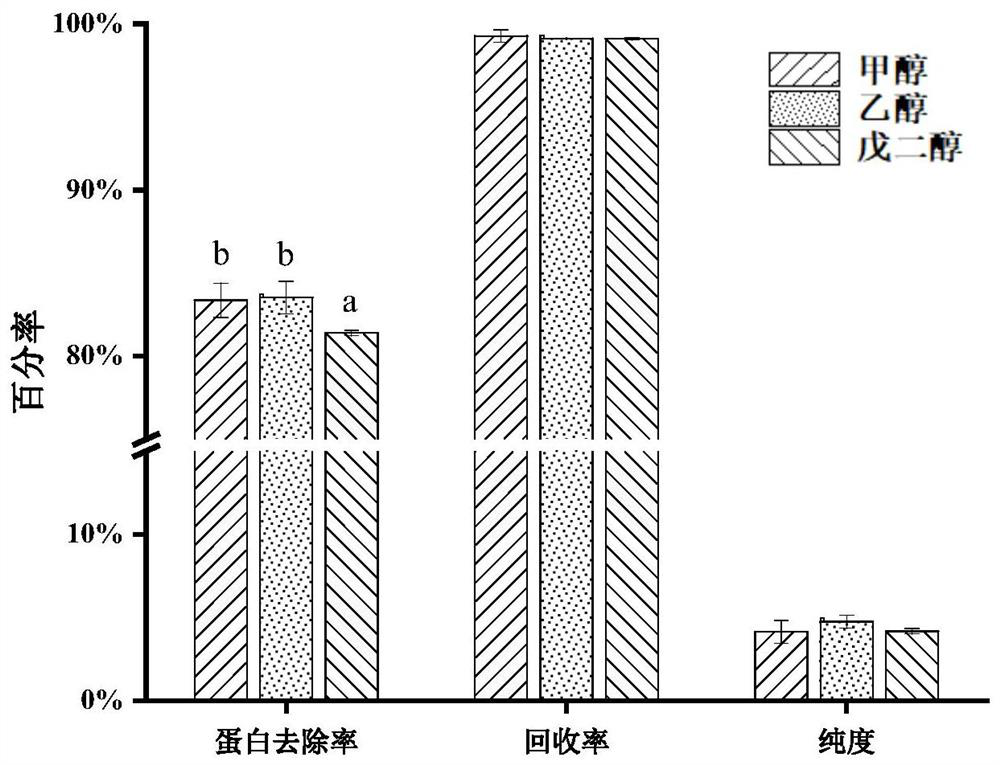

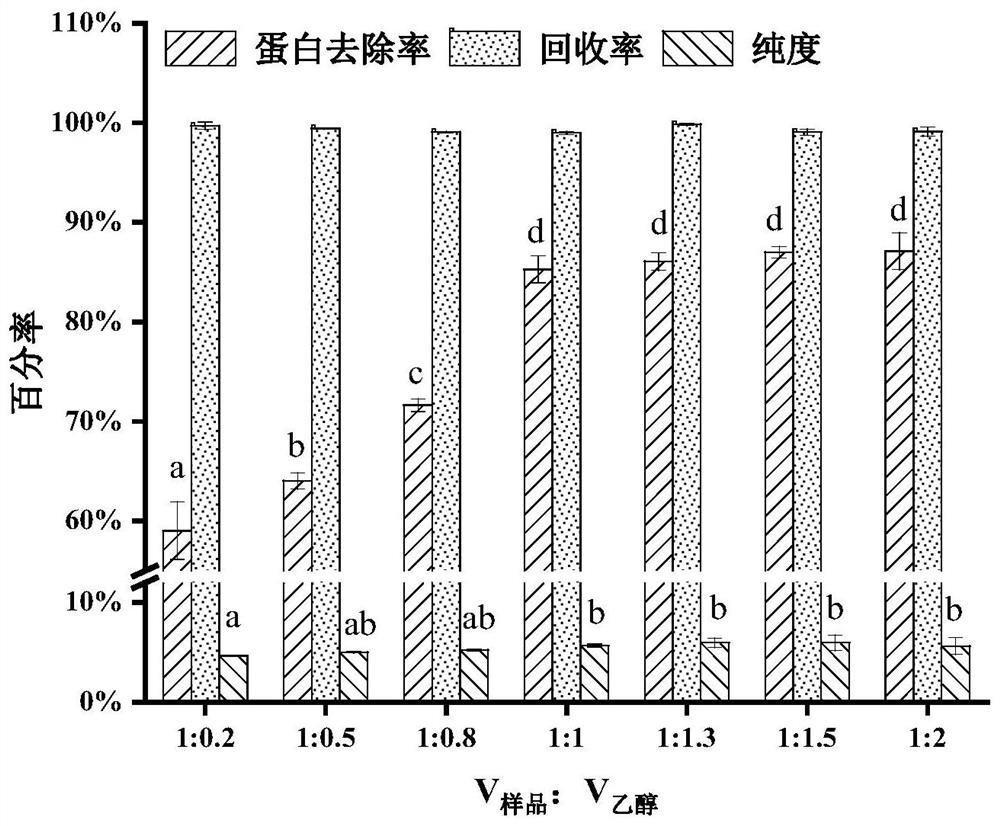

[0042] Embodiment 3 calculates recovery rate and purity, protein removal rate of surfactin

[0043] Recovery rate:

[0044] purity:

[0045] Protein removal rate:

[0046] Calculation of the content of surfactin: Quantitative analysis of the concentration of surfactin in the culture medium was carried out by ultra-high performance liquid chromatography (UPLC). Using Waters BEH C 18 Chromatographic column (100mm×2.1mm, 1.7μm particle) for liquid phase gradient separation; mobile phase A is 0.1% formic acid aqueous solution, mobile phase B is HPLC grade methanol; elution gradient: 0.1min, 70% B; 0.1–2.0min , 70% B; 2.0–8.0 min, 70%–100% B; 8.0–10 min, 100% B; 10.1 min, 70% B, 10.1–13 min 70% B; the flow rate was 0.3 mL / min. The UV detection wavelength is 205nm. Configure methanol standard solutions of surfactin with different concentration gradients, and make a surfactin standard curve according to the changes in peak area and concentration. Then, according to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com