Hydrogen-steam combined cycle power generation system and method based on aluminum-water reaction

A combined cycle power generation and water reaction technology, applied in steam engine installations, solar thermal power generation, combined combustion mitigation, etc., can solve the problems of low energy utilization efficiency, high power generation cost, high realization cost, and reduce instability and intermittent , the effect of improving energy conversion efficiency and reducing power generation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

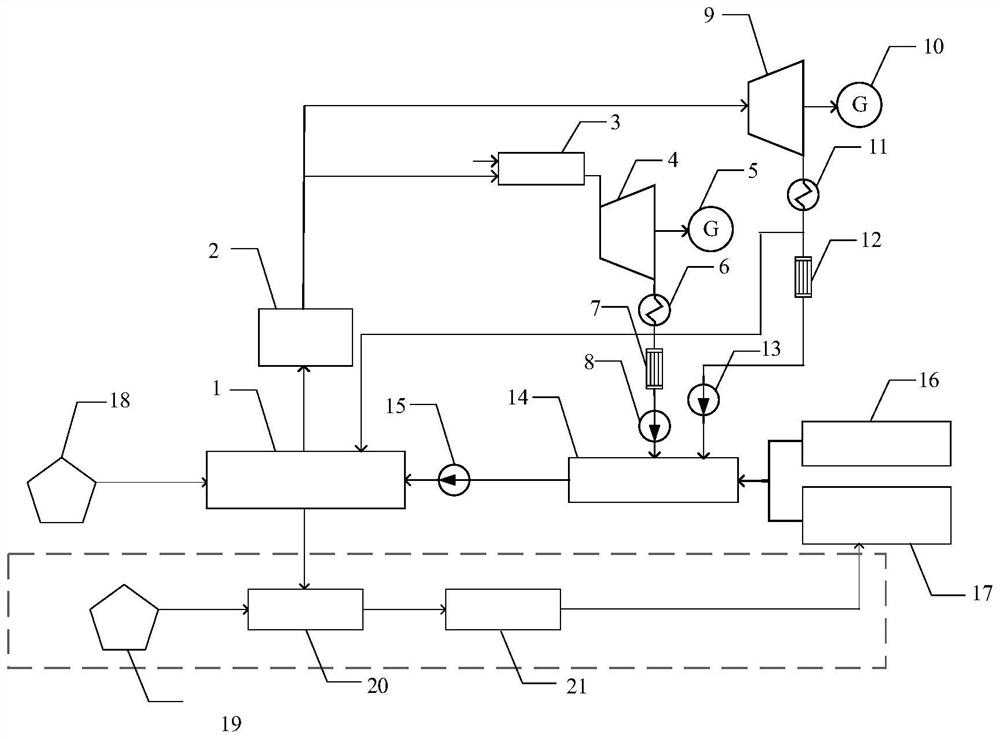

[0028] see figure 1 , The present invention provides a gas-steam combined cycle power generation system based on aluminum-water reaction, including an aluminum-water reactor 1, a hydrogen-steam separator 2, a combustion chamber 3, a hydrogen gas turbine 4, and a hydrogen gas permeator. Flat generator 5, first heat exchanger 6, first condenser 7, first circulation pump 8, steam turbine 9, steam turbine generator 10, second heat exchanger 11, second condenser 12, first Secondary circulation pump 13, aluminum-water mixing tank 14, high-pressure water pump 15, water storage tower 16, aluminum powder storage system 17, solar thermal heating system 18, renewable energy power supply system 19, electrolytic aluminum device 20, and aluminum pellets 21 . The system integrates the aluminum-water reaction exothermic process and the waste heat utilization process, uses membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com