Catalyst-free preparation method and application of porous helical carbon material

A technology of carbon materials and catalysts, applied in the field of catalyst-free preparation of porous helical carbon materials, can solve the problems of low controllability of experimental parameters, small specific surface area, limited use, etc., and achieve easy-to-obtain raw material sources, high specific surface area, The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

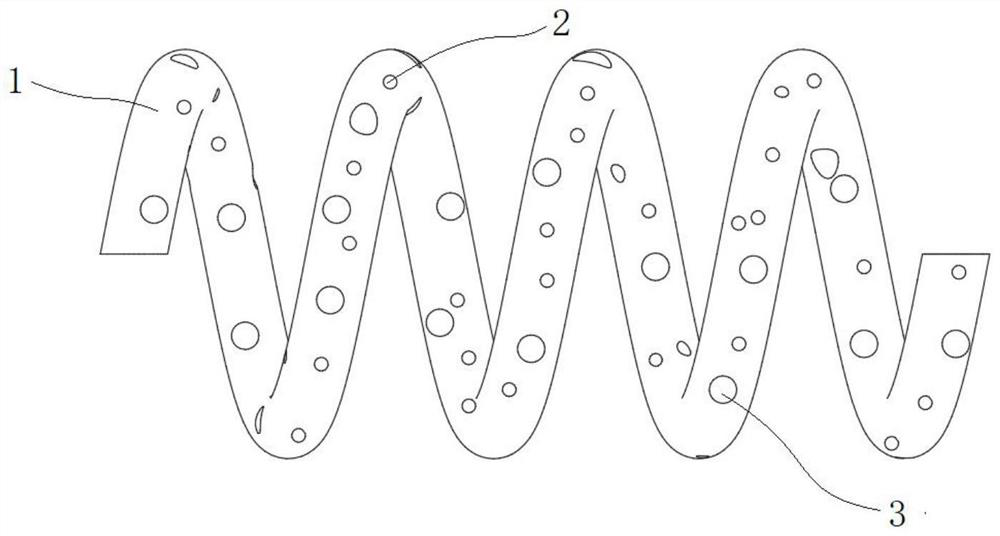

[0040] A catalyst-free preparation method and application of a porous helical carbon material proposed by the present invention, comprising the following steps:

[0041] S1, take the fallen leaves and wash them with ultrapure water to remove the dirt on the fallen leaves;

[0042] S2. Soak the washed leaves and fallen leaves in the corrosion solution solution and boil for 120min, rinse the sediment 4 times with ultrapure water; the corrosion solution is composed of calcium hydroxide and sodium hydroxide with a mass ratio of 80:80:80:1200 , sodium sulfite and ultrapure water;

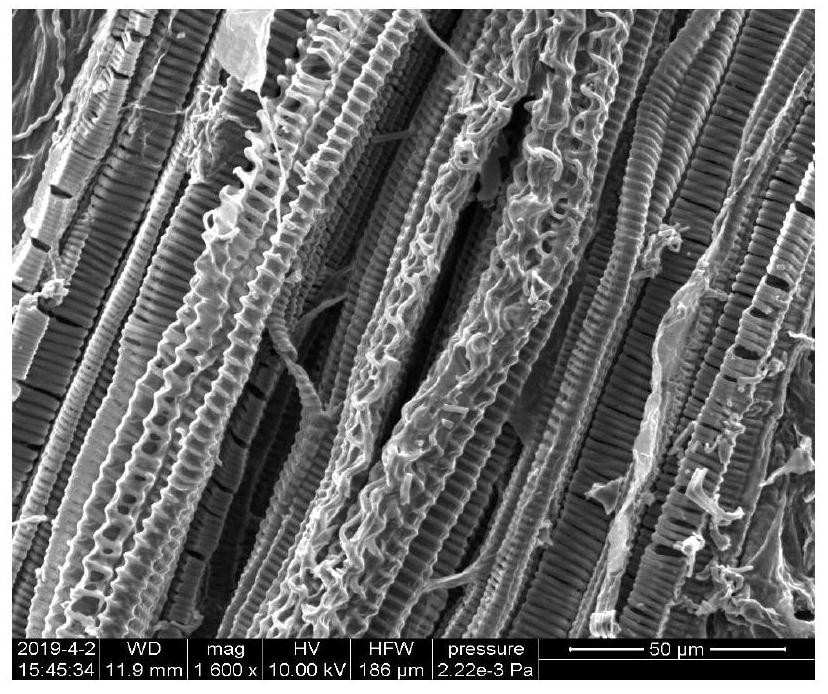

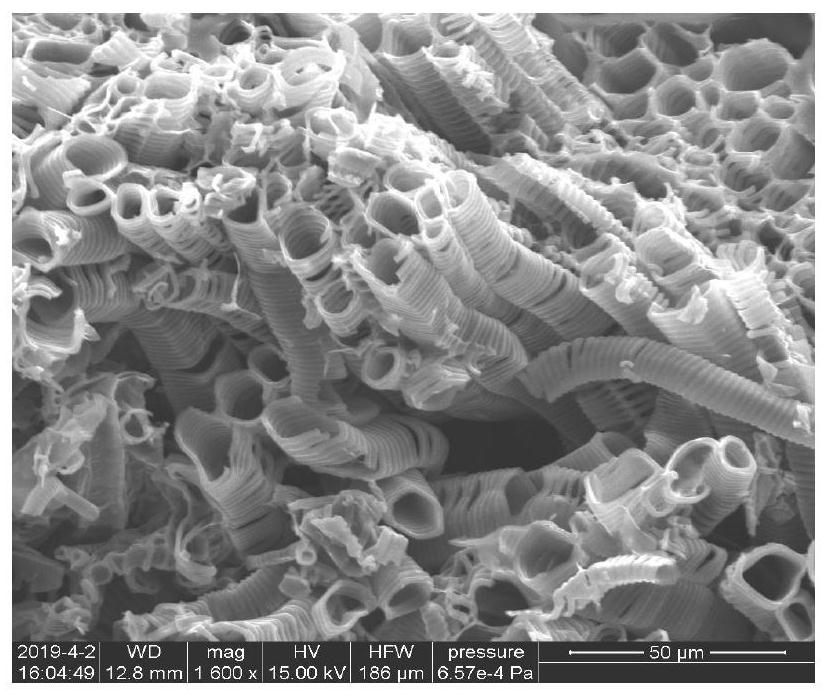

[0043] S3, ultrasonically treat the washed precipitate in a sulfuric acid solution with a volume concentration of 25% for 1 hour, wash it with deionized water and alcohol for 5 times, and collect the aggregates of the threaded catheter;

[0044] S4. Put the agglomerate of the threaded catheter into a vacuum freeze dryer, and freeze-dry at -80°C for 24 hours to obtain the threaded catheter;

[0045] S5,...

Embodiment 2

[0048] A catalyst-free preparation method and application of a porous helical carbon material proposed by the present invention, comprising the following steps:

[0049] S1, take the fallen leaves and wash them with ultrapure water to remove the dirt on the fallen leaves;

[0050] S2, soak the washed leaves and fallen leaves in the corrosion solution solution and boil for 60min, rinse the sediment 4 times with ultrapure water; the corrosion solution is composed of calcium hydroxide and sodium hydroxide with a mass ratio of 80:80:80:1200 , sodium sulfite and ultrapure water;

[0051] S3, ultrasonically treat the washed precipitate in a sulfuric acid solution with a volume concentration of 30% for 1 hour, wash it with deionized water and alcohol for 5 times, and collect the aggregates of the threaded catheter;

[0052] S4. Put the agglomerate of the threaded catheter into a vacuum freeze dryer, and freeze-dry at -80°C for 24 hours to obtain the threaded catheter;

[0053] S5, ...

Embodiment 3

[0056] A catalyst-free preparation method and application of a porous helical carbon material proposed by the present invention, comprising the following steps:

[0057] S1, take the fallen leaves and wash them with ultrapure water to remove the dirt on the fallen leaves;

[0058] S2. Soak the washed leaves and fallen leaves in an aqueous lime solution and boil for 60 minutes, rinse the sediment 3 times with ultrapure water; the corrosion solution is composed of calcium hydroxide, sodium hydroxide, sodium hydroxide, and Sodium sulfite and ultrapure water;

[0059] S3, ultrasonically treat the washed precipitate in a sulfuric acid solution with a volume concentration of 25% for 1 hour, wash with deionized water and alcohol for 3 times, and collect the aggregates of the threaded catheter;

[0060] S4. Put the agglomerate of the threaded catheter into a vacuum freeze dryer, and freeze-dry at -80°C for 24 hours to obtain the threaded catheter;

[0061] S5, get the threaded condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com