Method for preparing industrial-grade collagen and chromium tannin retanning agent from chromium-containing leather crushed materials and application

A technology for chromium tannin retanning agent and raw protein, which is applied in the field of chemical and chemical industry, can solve the problem of failing to effectively prepare high-quality collagen and chromium tannin retanning agent, and failing to realize the recycling of chromium-containing leather scraps. Chromium-containing sludge cannot be fully digested, etc., to achieve the effect of low treatment cost, realization of resource recycling, and reduction of the pressure of treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

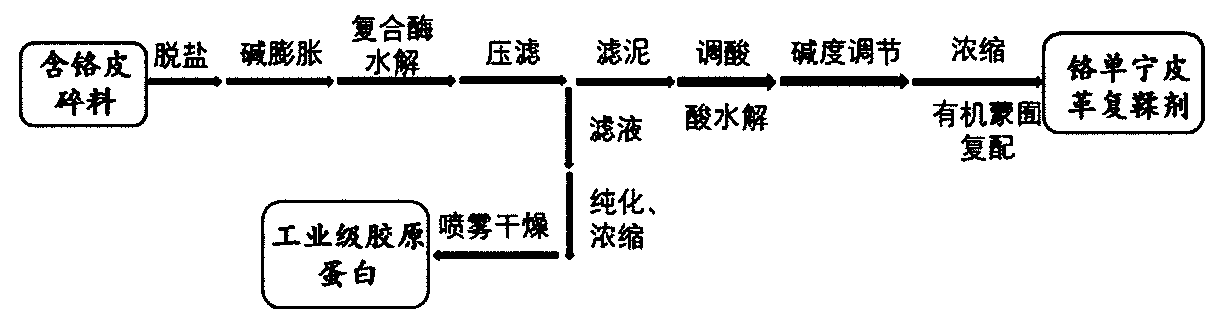

Method used

Image

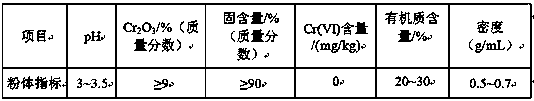

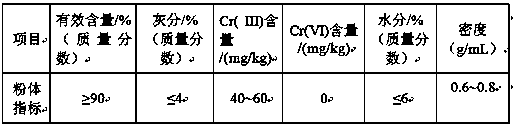

Examples

Embodiment 1

[0023] Example 1 A method of preparing industrial-grade collagen and chrome tannin retanning agent with chrome-containing leather scraps

[0024] (1) Washing and desalting with water

[0025] Add 1.5 t of chrome-containing dander and 3.0 t of water to a wooden drum with a diameter of 3.5 m, rotate at a speed of 30 r / min, adjust the temperature to 45°C, rotate and wash for 60 min, squeeze water, and control drying to obtain the moisture content of dander If it is above 60%, reserve;

[0026] (2) Alkali expansion

[0027] Add the skin flakes after washing and desalting with water in step (1) into an 8 t stainless steel reactor, add 3.0 t of water, stir and disperse, add about 150 kg of sodium hydroxide solution, and adjust the pH to 8.5~9.5. Set the reaction kettle: the temperature is 55°C, keep warm for 10 h, the stirring speed is 40 r / min, stop stirring after stirring for 5 minutes, and continue stirring after stopping for 55 minutes; the sodium hydroxide solution: the mass ...

Embodiment 2

[0040] Embodiment 2 A method for preparing technical grade collagen and chrome tannin retanning agent with chrome-containing leather scraps

[0041] (1) Washing and desalting with water

[0042] Add 1.5 t of chrome-containing dander and 3.0 t of water into a wooden drum with a diameter of 3.5 m, rotate at a speed of 20 r / min, adjust the temperature to 50°C, rotate and wash for 90 min, squeeze the water, and control the drying to obtain the moisture content of the dander at More than 60%, reserve;

[0043] (2) Alkali expansion

[0044] Add the skin flakes after washing and desalting with water in step (1) into an 8 t stainless steel reactor, add 3.0 t of water, stir and disperse, add about 150 kg of sodium hydroxide solution, and adjust the pH to 8.5~9.5. Set the reaction kettle: the temperature is 45°C, keep warm for 12 h, stir at a speed of 50 r / min, stop stirring after stirring for 10 min, and continue stirring after stopping for 50 min; the sodium hydroxide solution: the ...

Embodiment 3

[0057] Embodiment 3 A kind of method that prepares technical grade collagen and chrome tannin retanning agent with chrome skin scrap

[0058] (1) Washing and desalting with water

[0059] Add 1.5 t of chrome-containing dander and 3.0 t of water to a wooden drum with a diameter of 3.5 m, rotate at a speed of 40 r / min, adjust the temperature to 40°C, rotate and wash for 80 min, squeeze the water, and control the drying to obtain dander with a moisture content of More than 60%, reserve;

[0060] (2) Alkali expansion

[0061] Add the skin flakes after washing and desalting with water in step (1) into an 8 t stainless steel reactor, add 3.0 t of water, stir and disperse, add about 150 kg of sodium hydroxide solution, and adjust the pH to 8.5~9.5. Set the reaction kettle: the temperature is 50°C, keep warm for 10 h, stir at a speed of 40 r / min, stop stirring after stirring for 5 min, and continue stirring after stopping for 55 min; the sodium hydroxide solution: the mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com