A kind of solder and method for welding molybdenum-rhenium alloy and steel

A technology of molybdenum-rhenium alloy and brazing material, which is applied in the field of welding molybdenum-rhenium alloy and steel, and the field of brazing material for welding molybdenum-rhenium alloy and steel. Problems, to achieve no forming defects, avoid processing damage, good forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

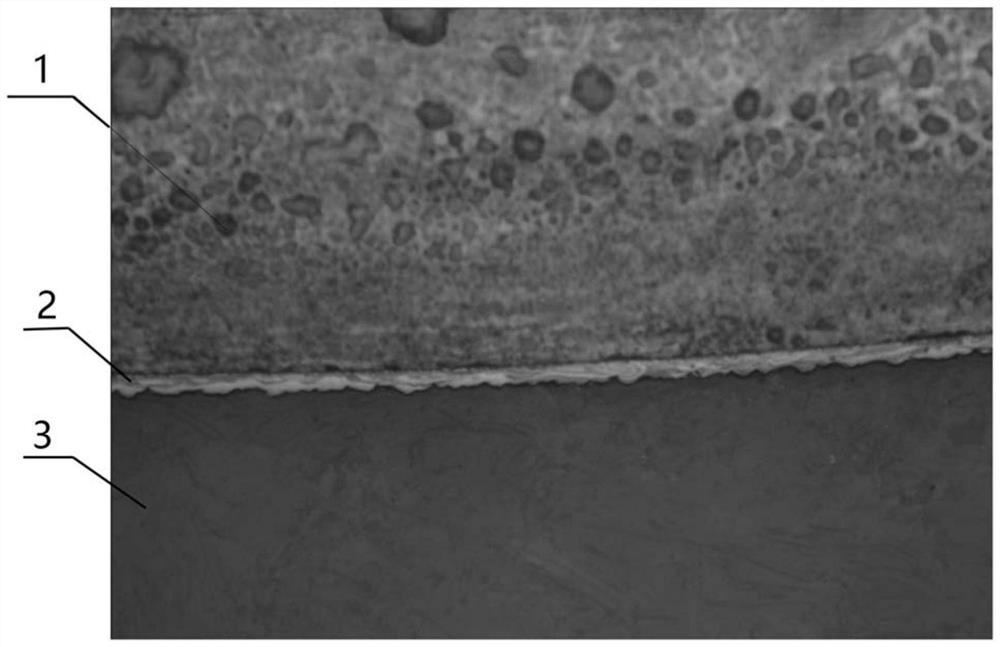

Image

Examples

Embodiment 1

[0038] The components and content of the solder powder are: Cr 10wt%, Co 3.5wt%, B 1wt%, the balance is Ni, and the particle size of the solder powder is 200-300 mesh.

[0039] The content of rhenium in the molybdenum-rhenium alloy in this embodiment is 45 wt%, and the stainless steel is S31608.

[0040] The specific welding process is as follows:

[0041] (1) The welding surface of the stainless steel parts is polished, the roughness is below Ra0.8, and then pickled (the pickling solution formula is: nitric acid: hydrofluoric acid: water = 2:1:5, volume ratio), water washing, Vacuum dry at 80°C for 1h. The welding surface of the molybdenum-rhenium alloy parts is ground, the roughness is below Ra0.8mm, and then annealed at 900°C for 1h in a hydrogen atmosphere.

[0042] (2) The brazing material is evenly laid on the molybdenum-rhenium alloy parts or stainless steel parts to be welded, the thickness is controlled at about 0.8mm, tooling is used up and down, and a pressure of ...

Embodiment 2

[0049] The components and content of the solder powder are: Cr 9wt%, Co3.5wt%, B 2wt%, the balance is Ni, and the particle size of the solder powder is 200-300 mesh.

[0050] The content of rhenium in the molybdenum-rhenium alloy in this embodiment is 45 wt%, and the stainless steel is S31608.

[0051] The specific welding process is as follows:

[0052] (1) The welding surface of the stainless steel parts is polished, the roughness is below Ra0.8, and then pickled (the pickling solution formula is: nitric acid: hydrofluoric acid: water = 2:1:5, volume ratio), water washing, Vacuum dry at 80°C for 1h. The welding surface of the molybdenum-rhenium alloy parts is ground, the roughness is below Ra0.8mm, and then annealed at 900°C for 1h in a hydrogen atmosphere.

[0053] (2) The brazing material is evenly laid on the molybdenum-rhenium alloy parts or stainless steel parts to be welded, the thickness is controlled at about 0.8mm, tooling is used up and down, and a pressure of 4M...

Embodiment 3

[0060] The components and content of the solder powder are: 6.5wt% of Cr, 3.5wt% of Co, 3wt% of B, the balance is Ni, and the particle size of the solder powder is 200-300 mesh.

[0061] The content of rhenium in the molybdenum-rhenium alloy in this embodiment is 45 wt%, and the stainless steel is S31608.

[0062] The specific welding process is as follows:

[0063] (1) The welding surface of the stainless steel parts is polished, the roughness is below Ra0.8, and then pickled (the pickling solution formula is: nitric acid: hydrofluoric acid: water = 2:1:5, volume ratio), water washing, Vacuum dry at 80°C for 1h. The welding surface of the molybdenum-rhenium alloy parts is ground, the roughness is below Ra0.8mm, and then annealed at 900°C for 1h in a hydrogen atmosphere.

[0064] (2) The brazing material is evenly laid on the molybdenum-rhenium alloy parts or stainless steel parts to be welded, the thickness is controlled at about 0.8mm, tooling is used up and down, and a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com