Abrasive paper hydrophilic coating

A hydrophilic coating and hydrophilic technology, applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problem of non-hydrophilic adhesive film layer, poor initial sharpness of sandpaper, and clogging of the grinding layer on the surface of sandpaper and other problems, to achieve the effect of improving hydrophilicity, good suspension, and not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

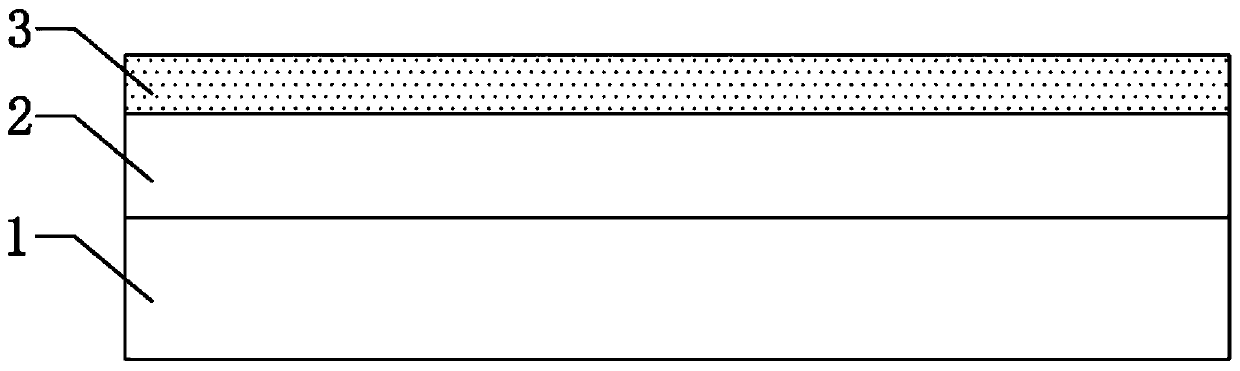

Image

Examples

Embodiment 1

[0036] A kind of sandpaper hydrophilic coating is characterized in that: comprise the raw material of following weight part:

[0037] Abrasive 80 parts

[0038] Adhesive 10 parts

[0039] Hydrophilic additive 1 part.

[0040] The abrasive is alumina.

[0041] The adhesive is polyurethane adhesive.

[0042] The hydrophilic auxiliary agent is fatty alcohol polyoxyethylene ether AEO-7, and the HLB value is 12.

[0043] Described abrasive is the modified abrasive of modified treatment, and described modified abrasive is made by following steps:

[0044] (1) Mix allyl alcohol polyoxyethylene ether with deionized water, add polyethylene glycol after dispersing evenly, and prepare a pre-dispersion;

[0045] (2) Add the abrasive to the pre-dispersed liquid prepared in step (1), stir at room temperature for 15 minutes, then heat up to 75°C, and under the irradiation of ultraviolet rays with a wavelength of 328nm, stir for 30 minutes, then add calcium carbonate, and stir evenly. P...

Embodiment 2

[0053] A kind of sandpaper hydrophilic coating is characterized in that: comprise the raw material of following weight part:

[0054] Abrasive 82 parts

[0055] Adhesive 12 parts

[0056] Hydrophilic additive 2 parts.

[0057] The abrasive is silicon carbide.

[0058] The adhesive is epoxy resin adhesive.

[0059] The hydrophilic auxiliary agent is sodium oleate, and the HLB value is 18.

[0060] Described abrasive is the modified abrasive of modified treatment, and described modified abrasive is made by following steps:

[0061] (1) Mix allyl alcohol polyoxyethylene ether with deionized water, add polyethylene glycol after dispersing evenly, and prepare a pre-dispersion;

[0062] (2) Add the abrasive to the pre-dispersed liquid prepared in step (1), stir at room temperature for 16 minutes, then heat up to 76°C, and under the irradiation of ultraviolet rays with a wavelength of 334nm, stir for 28 minutes, then add calcium carbonate, and stir evenly. Prepare the mixture a...

Embodiment 3

[0070] A kind of sandpaper hydrophilic coating is characterized in that: comprise the raw material of following weight part:

[0071] Abrasive 85 parts

[0072] Adhesive 15 parts

[0073] 3 parts of hydrophilic additives.

[0074] The abrasive is a mixture of aluminum oxide and silicon carbide at a weight ratio of 1:1.

[0075] The adhesive is a mixture of polyurethane adhesive and epoxy resin adhesive with a weight ratio of 1:1.

[0076] The hydrophilic auxiliary agent is a mixture of sodium lauryl sulfate and sodium oleate, wherein the mixing weight ratio of sodium lauryl sulfate and sodium oleate is 40:60, and the HLB value is 30.

[0077] Described abrasive is the modified abrasive of modified treatment, and described modified abrasive is made by following steps:

[0078] (1) Mix allyl alcohol polyoxyethylene ether with deionized water, add polyethylene glycol after dispersing evenly, and prepare a pre-dispersion;

[0079] (2) Add the abrasive to the pre-dispersed liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com