Ferromanganese-based magnetic refrigeration material with low heat stagnation and preparation method and application thereof

A magnetic refrigeration material, ferromanganese technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of reducing effective refrigeration capacity and limiting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

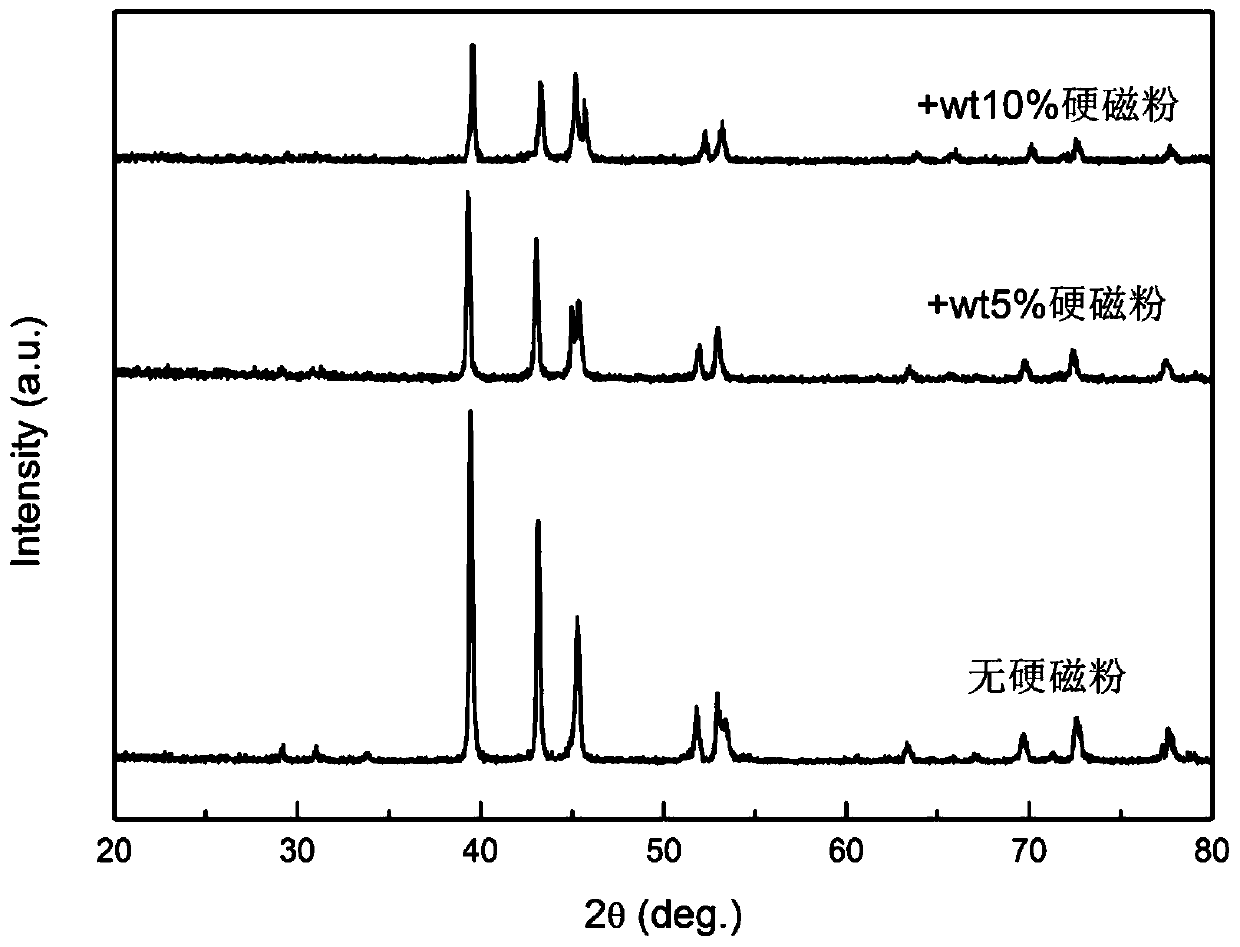

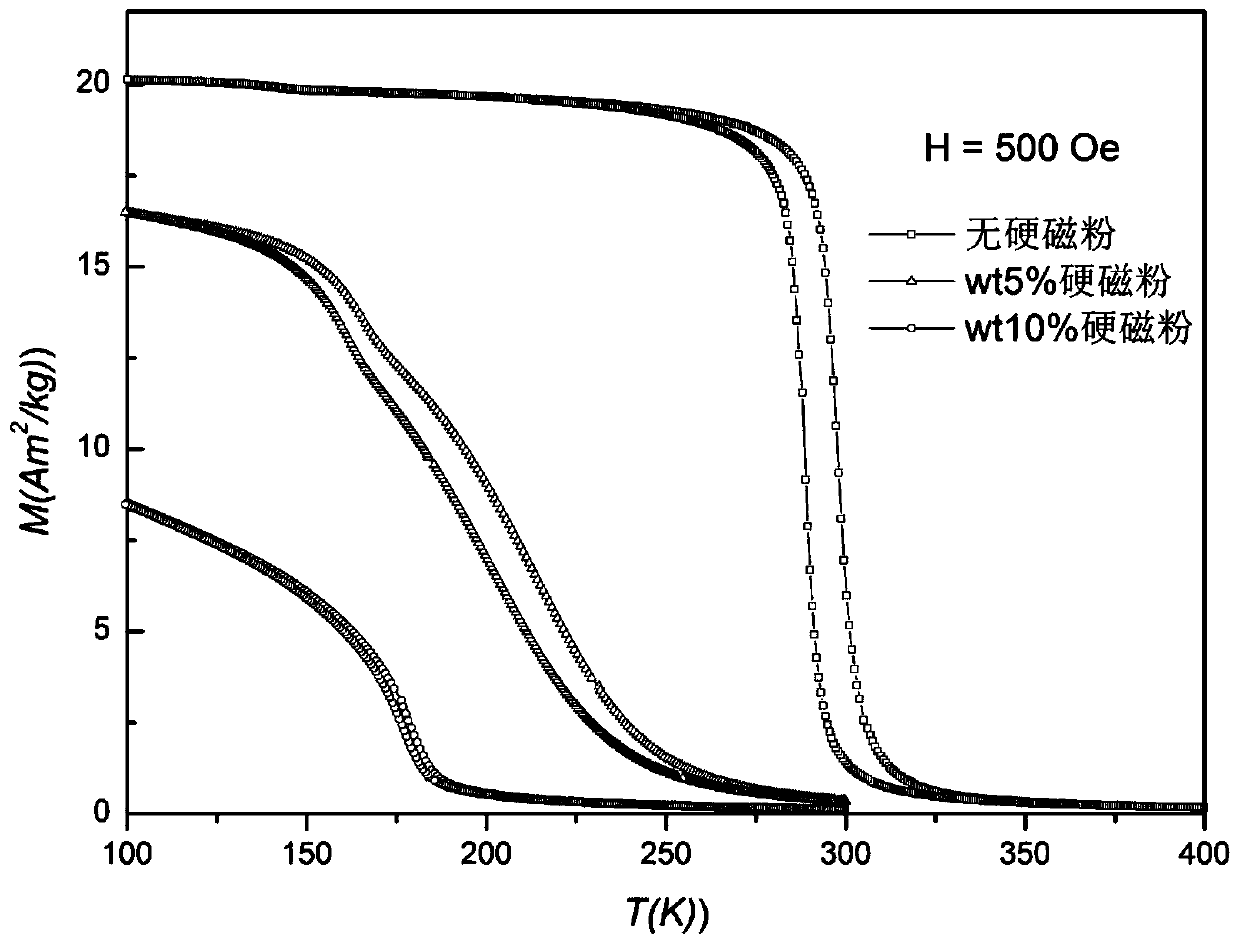

[0033] A ferromanganese-based magnetic refrigeration material with low thermal hysteresis is produced by sintering hard magnetic powder and mixed powder containing manganese and iron, wherein the hard magnetic powder is N50 NdFeB magnet. The preparation method of the ferromanganese-based magnetic refrigeration material comprises the steps: the raw materials of the mixed powder are manganese flakes, iron powder (purity ≥ 99.5%), silicon fragments (purity ≥ 99.9%) and red phosphorus powder (purity ≥ 98.9%), take the mixed The raw material of the powder and the nominal composition is Mn 1.2 Fe 0.75 P 0.5 Si 0.5 The molar ratio is used for batching. Mix the above mixed material with N50 hard magnetic powder in a mass ratio of 100:0 to batch 20g. All raw materials were milled in a high-energy ball mill for 5 hours at a ball-to-material ratio of 10:1, and then the powder obtained by ball milling was put into a graphite mold and placed in a LABOX-2010Khv spark plasma sintering (S...

Embodiment 2

[0035] A ferromanganese-based magnetic refrigeration material with low thermal hysteresis is produced by sintering hard magnetic powder and mixed powder containing manganese and iron, wherein the hard magnetic powder is N50 NdFeB magnet. The preparation method of the ferromanganese-based magnetic refrigeration material comprises the steps: the raw materials of the mixed powder are manganese flakes, iron powder (purity ≥ 99.5%), silicon fragments (purity ≥ 99.9%) and red phosphorus powder (purity ≥ 98.9%), take the mixed The raw material of the powder and the nominal composition is Mn 1.2 Fe 0.75 P 0.5 Si 0.5 The molar ratio is used for batching. Mix the above mixed material with N50 hard magnetic powder in a mass ratio of 95:5 for 20g. All raw materials were milled in a high-energy ball mill for 5 hours at a ball-to-material ratio of 10:1, and then the powder obtained by ball milling was put into a graphite mold and placed in a LABOX-2010Khv spark plasma sintering (SPS) sy...

Embodiment 3

[0037] A ferromanganese-based magnetic refrigeration material with low thermal hysteresis is produced by sintering hard magnetic powder and mixed powder containing manganese and iron, wherein the hard magnetic powder is N50 NdFeB magnet. The preparation method of the ferromanganese-based magnetic refrigeration material comprises the steps: the raw materials of the mixed powder are manganese flakes, iron powder (purity ≥ 99.5%), silicon fragments (purity ≥ 99.9%) and red phosphorus powder (purity ≥ 98.9%), take the mixed The raw material of the powder and the nominal composition is Mn1.2 Fe 0.75 P 0.5 Si 0.5 The molar ratio is used for batching. Mix the above mixed material with N50 hard magnetic powder in a mass ratio of 90:10 for 20g. All raw materials were milled in a high-energy ball mill for 5 hours at a ball-to-material ratio of 10:1, and then the powder obtained by ball milling was put into a graphite mold and placed in a LABOX-2010Khv spark plasma sintering (SPS) sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com