Fuel cell bipolar plate with controllable pressure difference between flow channels

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell parts, circuits, etc., can solve the problem of low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

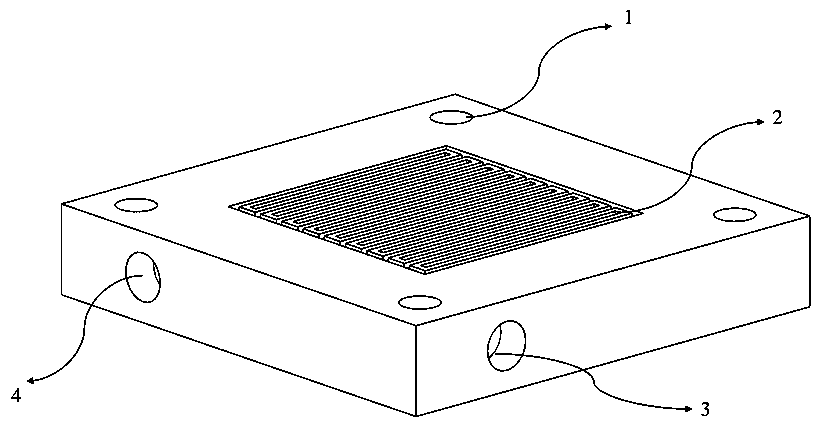

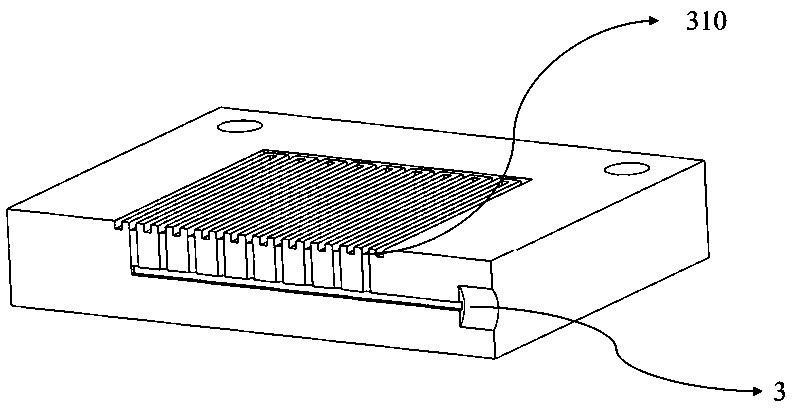

[0097] A fuel cell bipolar plate with controllable pressure difference between flow channels, including a square gas flow channel field and several parallel "back" shaped ribs 2 arranged in parallel in the gas flow channel field, used to fix the holes 1 of the bipolar plate They are respectively located at the corners of the runner field, the inlet hole 3 of the inner runner is arranged on one side of the bipolar plate, the outlet hole 6 of the inner runner is arranged on the opposite side of the inlet hole 3 of the inner runner; the outer runner The air inlet hole 4 of the outer runner is arranged on the adjacent side of the inlet hole 3 of the inner runner, and the air outlet hole 5 of the outer runner is arranged on the opposite side of the inlet hole 4 of the outer runner. The several "back" shaped ribs 2 are evenly distributed in parallel in the gas flow channel field, each "back" shaped rib is a unit, the inside and outside of the "back" shaped rib form a double flow chan...

Embodiment 2

[0099] A fuel cell bipolar plate with controllable pressure difference between flow channels, including a square gas flow channel field and several parallel "back" shaped ribs 2 arranged in parallel in the gas flow channel field, used to fix the holes 1 of the bipolar plate They are respectively located at the corners of the runner field, the inlet hole 3 of the inner runner is arranged on one side of the bipolar plate, the outlet hole 6 of the inner runner is arranged on the opposite side of the inlet hole 3 of the inner runner; the outer runner The air inlet hole 4 of the outer runner is arranged on the adjacent side of the inlet hole 3 of the inner runner, and the air outlet hole 5 of the outer runner is arranged on the opposite side of the inlet hole 4 of the outer runner. The several "back" shaped ribs 2 are evenly distributed in parallel in the gas flow channel field, each "back" shaped rib is a unit, the inside and outside of the "back" shaped rib form a double flow chan...

Embodiment 3

[0104] A fuel cell bipolar plate with controllable pressure difference between flow channels, including a square gas flow channel field and several parallel "back" shaped ribs 2 arranged in parallel in the gas flow channel field, used to fix the holes 1 of the bipolar plate They are respectively located at the corners of the runner field, the inlet hole 3 of the inner runner is arranged on one side of the bipolar plate, the outlet hole 6 of the inner runner is arranged on the opposite side of the inlet hole 3 of the inner runner; the outer runner The air inlet hole 4 of the outer runner is arranged on the adjacent side of the inlet hole 3 of the inner runner, and the air outlet hole 5 of the outer runner is arranged on the opposite side of the inlet hole 4 of the outer runner. The several "back" shaped ribs 2 are evenly distributed in parallel in the gas flow channel field, each "back" shaped rib is a unit, the inside and outside of the "back" shaped rib form a double flow chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com