Sodium fuel cell and cell stack containing sodium fuel cell

A fuel cell and battery stack technology, which is applied in the fields of fuel cells, fuel cell grouping, solid electrolyte fuel cells, etc. The effect of reaction rate, reduction of battery internal resistance, and improvement of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

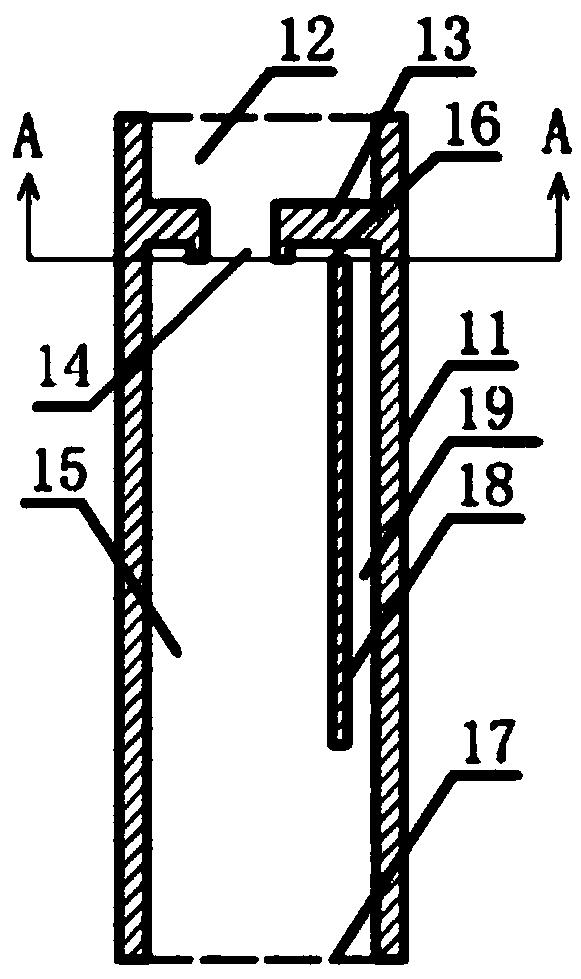

[0034] Such as figure 1As shown, a sodium fuel cell is composed of a cathode flow field plate 55, a gas cathode 51, an electrolyte membrane 54, and an anode flow field plate 56 in sequence, and the anode flow field plate 56 and the electrolyte membrane 54 are enclosed to form an anode The flow channel also includes an insulating drip tube 1, the inlet end of the anode flow channel is connected to a first insulating drip tube 1-1, and the outlet end of the anode flow channel is connected to a second insulating drip tube 1-2 , the anode flow channel is injected with molten sodium through the first insulating drip tube 1-1; the cavity between the cathode flow field plate 55 and the gas cathode 51 is injected with an oxidant.

[0035] A further technical solution is: the working temperature of the sodium fuel cell is not lower than the melting point of sodium; the oxidant is a mixed gas containing oxygen and water, including humidifying air and humidifying oxygen.

[0036] A furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com