Preparation method of nickel-titanium-aluminum hydrotalcite supercapacitor electrode material with porous structure

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of not being able to fully exert the performance of supercapacitors, low utilization of electrochemical active sites, and reducing the specific surface area of materials, etc. , to achieve the effect of shortening the ion transmission distance, increasing the electrochemical reaction rate, and improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

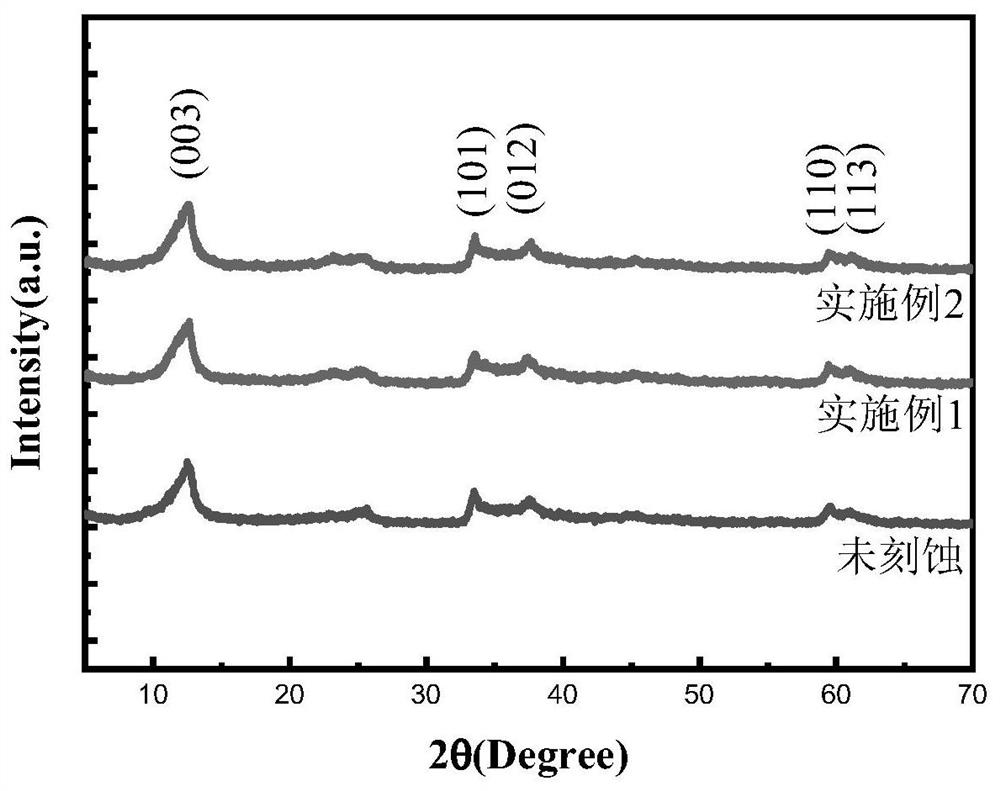

Embodiment 1

[0026] Weigh 3mmol of nickel sulfate, 0.5mmol of titanium sulfate, and 0.1mmol of aluminum sulfate and dissolve them in deionized water to form a 40ml mixed solution, and weigh 4mmol of urotropine and dissolve them in deionized water to form a 40ml solution. The two solutions were mixed and stirred for 10 minutes, transferred to a hydrothermal reaction kettle and sealed, and hydrothermally reacted at 160°C for 4 hours, and the obtained precipitate was filtered and washed and dried in an oven at 60°C for 10 hours, and the dried cake was ground to obtain hydrotalcite Powder, disperse the hydrotalcite powder into 5mol / L NaOH solution for etching, the etching time is 18h, and then use 6mol / L NaOH solution to clean, then wash with deionized water until neutral, dry and grind into pink. In this example, the obtained porous hydrotalcite powder has a relatively high specific surface area of 203.59m 2 / g.

[0027] Among them, the electrochemical test was measured under three-electr...

Embodiment 2

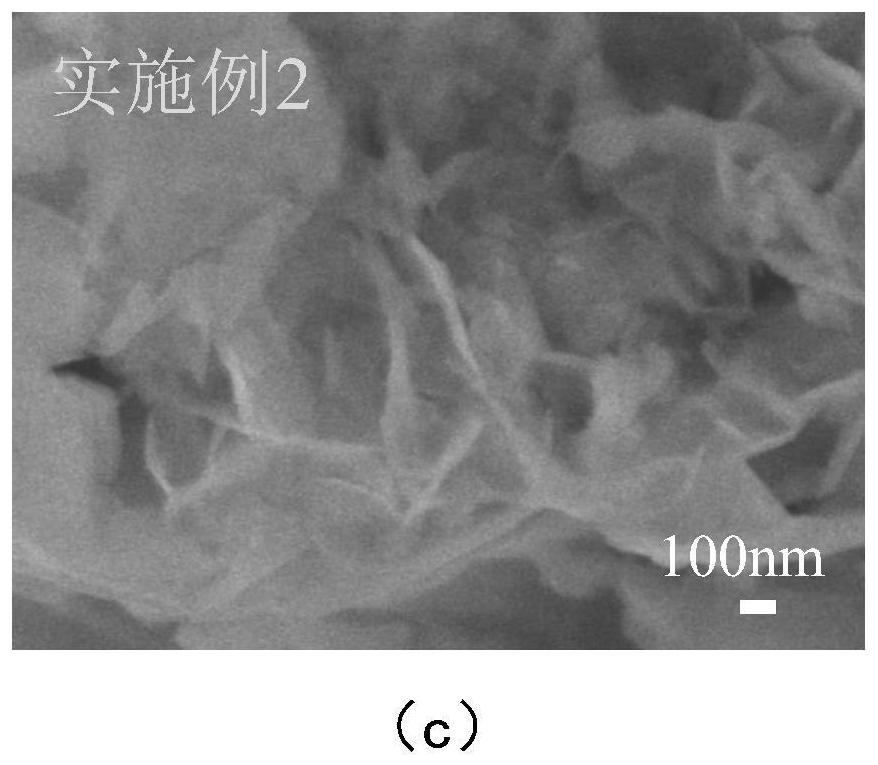

[0030] Weigh 3mmol of nickel sulfate, 0.5mmol of titanium sulfate, and 0.1mmol of aluminum sulfate, and dissolve them in deionized water to form a 40ml mixed solution. Weigh 2mmol of urotropine and dissolve them in deionized water to form a 40ml solution. The two solutions were mixed and stirred for 10 minutes, transferred to a hydrothermal reaction kettle and sealed, and hydrothermally reacted at 160°C for 4 hours, and the obtained precipitate was filtered and washed and dried in an oven at 60°C for 10 hours, and the dried cake was ground to obtain hydrotalcite powder , disperse the hydrotalcite powder into 5mol / L NaOH solution for etching, the etching time is 24h, and then wash it with 6mol / L NaOH solution, then wash it with deionized water until it is neutral, dry it and grind it into powder . In this example, the obtained porous hydrotalcite powder has a higher specific surface area of 199.49m 2 / g.

[0031] Among them, the electrochemical test was measured under three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com