Preparation method of rare-earth-doped lithium titanate ultrathin nanosheet negative electrode material

A negative electrode material and rare earth doping technology, which is applied in the field of preparation of rare earth doped lithium titanate ultra-thin nanosheet negative electrode materials, can solve the problems of improving electrical conductivity, complicated process, high cost and energy consumption, and achieves uniform distribution and process. The effect of simple, excellent capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

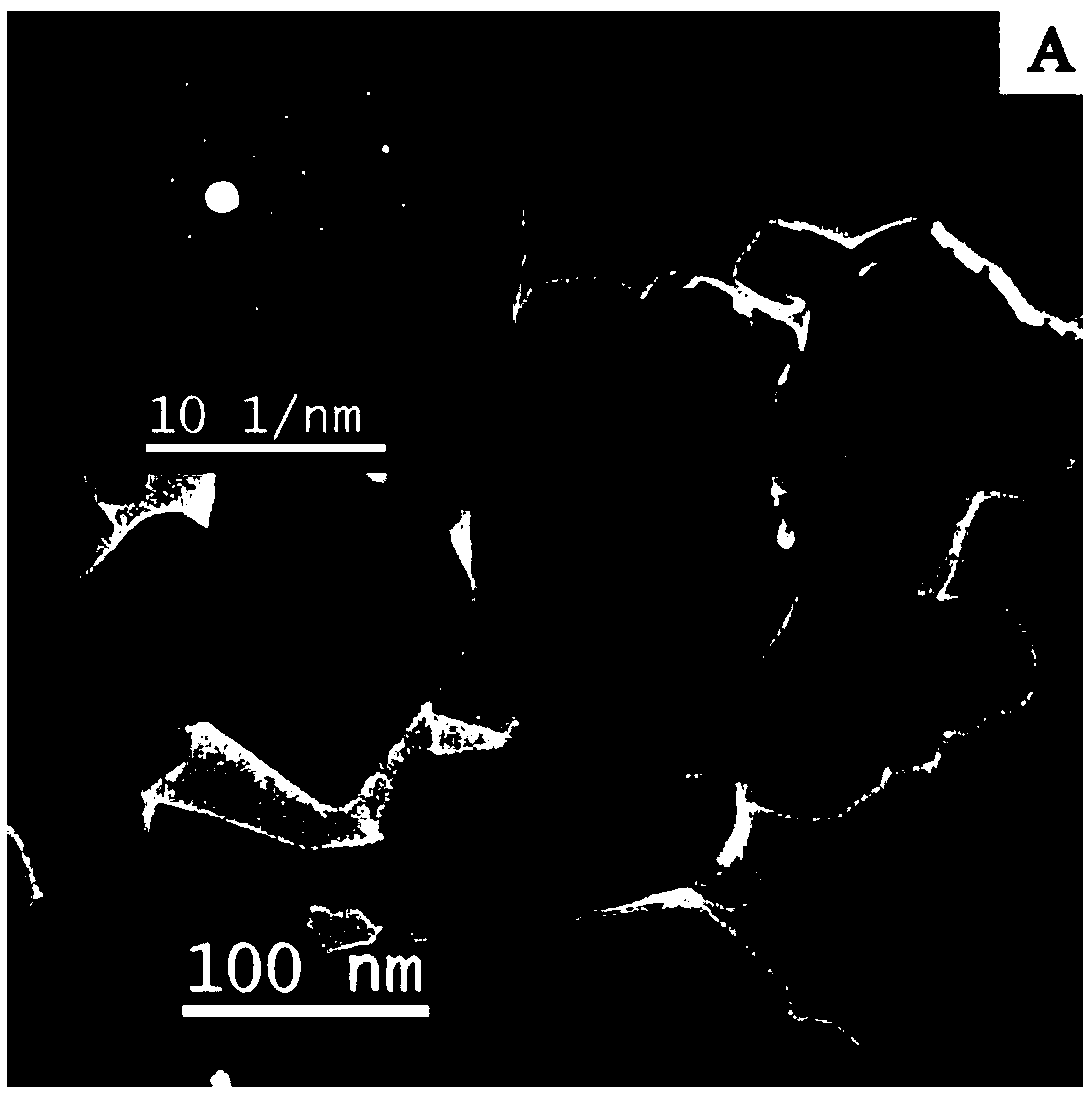

Image

Examples

Embodiment 1

[0026] 1) Add 0.01mol of LiOH·H 2 O, 3ml of tetrabutyl titanate and 0.08mmol of CeCl 3 ·7H 2 Pour O into a beaker and ultrasonically disperse it in an ultrasonic machine for 20 minutes to make it evenly dispersed, then place it on a magnetic stirrer, add 15ml of ethanol and then 20ml of deionized water at 350r / min, and stir for 4 hours to obtain Mixed homogeneous suspension;

[0027] 2) Transfer the homogeneously mixed suspension in step 1 to a hydrothermal kettle, heat to 180°C, react for 48 hours, then cool to 25°C, and then use 80ml of ethanol to filter the suspension under the condition of suction Washing 3 times to remove the remaining impurities inside the material, the precursor of the modified lithium titanate negative electrode material can be obtained;

[0028] 3) vacuum-drying the modified lithium titanate negative electrode material precursor obtained in step 2 at 60° C., and then grinding it into powder;

[0029] 4) Heat the ground powder at a rate of 2°C / min ...

Embodiment 2

[0032] 1) Add 0.008mol of LiOH·H 2 O, 2ml of tetrabutyl titanate and 0.04mmol of LaCl 3 ·7H 2 Pour O into a beaker and ultrasonically disperse it in an ultrasonic machine for 30 minutes to make it evenly dispersed, then place it on a magnetic stirrer, add 25ml of ethanol and then 30ml of deionized water at 200r / min, and stir for 2 hours to get Mixed homogeneous suspension;

[0033] 2) Transfer the homogeneously mixed suspension in step 1) to a hydrothermal kettle, heat to 150°C, react for 24 hours, then cool to 23°C, and then use 40ml of the suspension under the condition of suction filtration Washing with ethanol twice to remove the residual impurities inside the material, the precursor of the modified lithium titanate negative electrode material can be obtained;

[0034]3) vacuum-drying the modified lithium titanate negative electrode material precursor obtained in step 2) at 50° C., and then grinding it into powder;

[0035] 4) Heat the ground powder at a rate of 5°C / mi...

Embodiment 3

[0037] 1) Add 0.012mol of LiOH·H 2 O, 4ml of tetrabutyl titanate and 0.1mmol of CeCl 3 ·7H 2 Pour O into a beaker and ultrasonically disperse it in an ultrasonic machine for 25 minutes to make it evenly dispersed, then place it on a magnetic stirrer, add 20ml of ethanol and then 25ml of deionized water at 400r / min, and stir for 3 hours to obtain Mixed homogeneous suspension;

[0038] 2) Transfer the homogeneously mixed suspension in step 1) to a hydrothermal kettle, heat to 160°C, react for 36 hours, then cool to 24°C, and then use 60ml of the suspension under the condition of suction filtration Washing with ethanol for 3 times to remove the remaining impurities inside the material, the precursor of the modified lithium titanate negative electrode material can be obtained;

[0039] 3) vacuum-drying the modified lithium titanate negative electrode material precursor obtained in step 2) at 80° C., and then grinding it into powder;

[0040] 4) Heat the ground powder at a rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com