Defective K0.5Mn2O4 nano material, preparation method and zinc ion battery

A nanomaterial, defect-type technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of electrode material stability and poor conductivity, and achieve efficient diffusion, simple preparation process, and large capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

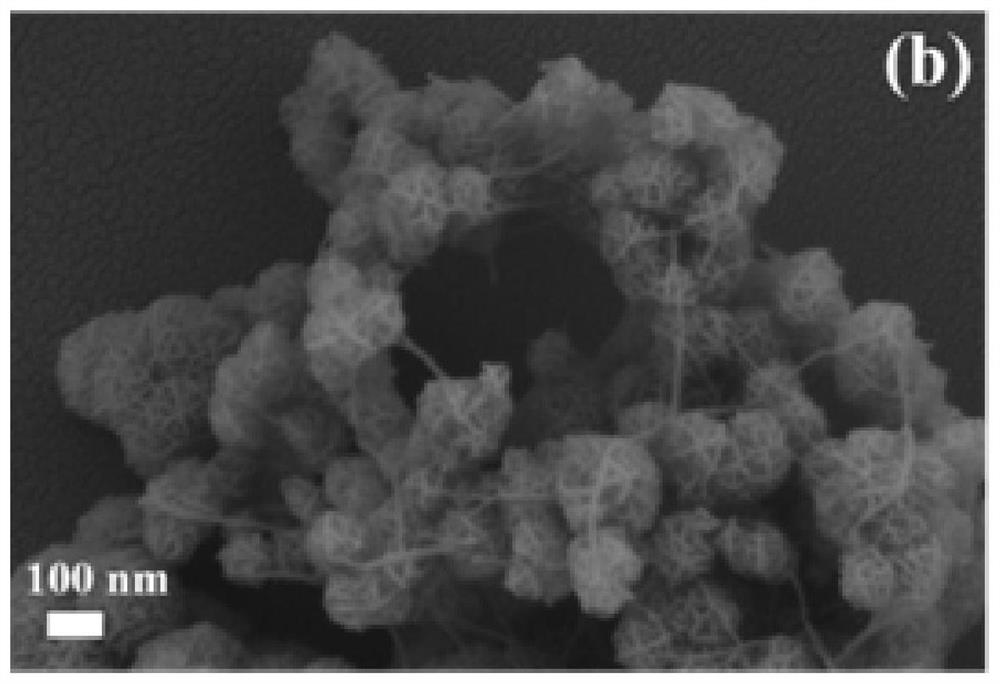

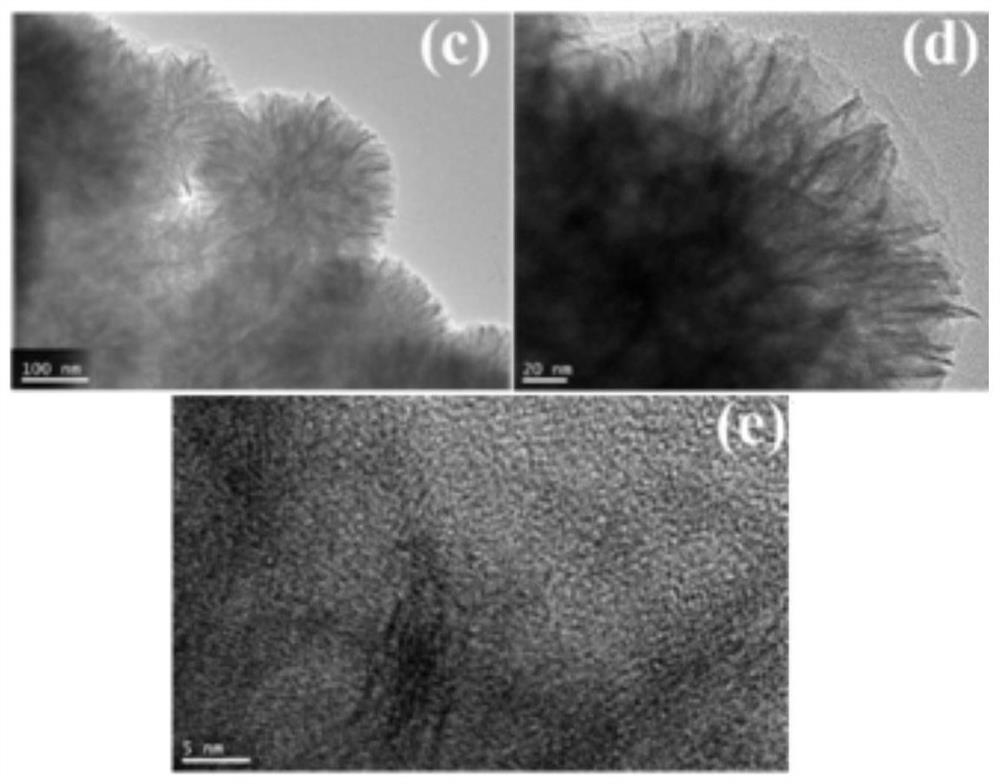

[0053] A defect in type K 0.5 Mn 2 O 4 The method of preparing an electrode material, comprising the steps of:

[0054] S1: The cut area is foamed nickel 1 × 2cm 2 Sheet sequentially subjected to ultrasonic cleaning in 3M hydrochloric acid, ethanol, an aqueous solution, the cleaning time was 10min; then cleaned by ultrasound through the nickel foam placed in an oven dried at 60 ℃ 10H, cleaned finally obtained foamed nickel substrate material .

[0055] S2: The potassium permanganate and ammonium oxalate were dissolved in 30mL of deionized water and stirred to give a uniform mixed solution dark purple.

[0056] S3: The mixed solution was transferred to a step S2 Teflon lined autoclave in the order, and added to a clean foamed nickel substrate material obtained in step S1 autoclave, for 24h at 90 ℃.

[0057] S4: After the reactor was cooled to room temperature to obtain K grown on the surface of the base material of nickel foam 0.5 Mn 2 O 4 Powder and then with anhydrous ethanol and...

Embodiment 2

[0060] A defect in type K 0.5 Mn 2 O 4 The method of preparing an electrode material, comprising the steps of:

[0061] S1: The cut area is foamed nickel 1 × 2cm 2 Sheet sequentially subjected to ultrasonic cleaning in 3M hydrochloric acid, ethanol, an aqueous solution, the cleaning time was 12min; then cleaned by ultrasonic foamed nickel was dried in an oven at 80 ℃ 10H treated, cleaned finally obtained foamed nickel substrate material .

[0062] S2: The potassium permanganate and ammonium oxalate were dissolved in 30mL of deionized water and stirred to give a uniform mixed solution dark purple.

[0063] S3: The mixed solution was transferred to a step S2 Teflon lined autoclave in the order, and added to a clean foamed nickel substrate material obtained in step S1 autoclave, for 24h at 90 ℃.

[0064] S4: After the reactor was cooled to room temperature to obtain K grown on the surface of the base material of nickel foam 0.5 Mn 2 O 4 Powder and then with anhydrous ethanol and wash...

Embodiment 3

[0067] A defect in type K 0.5 Mn 2 O 4 The method of preparing an electrode material, comprising the steps of:

[0068] S1: The cut area is foamed nickel 1 × 2cm 2 Sheet sequentially subjected to ultrasonic cleaning in 3M hydrochloric acid, ethanol, an aqueous solution, the cleaning time was 10min; then cleaned by ultrasound through the nickel foam placed in an oven dried at 60 ℃ 10H, cleaned finally obtained foamed nickel substrate material .

[0069] S2: The potassium permanganate and ammonium oxalate were dissolved in 30mL of deionized water and stirred to give a uniform mixed solution dark purple.

[0070] S3: The mixed solution was transferred to a step S2 Teflon lined autoclave in the order, and added to a clean foamed nickel substrate material obtained in step S1 autoclave, for 24h at 90 ℃.

[0071] S4: After the reactor was cooled to room temperature to obtain K grown on the surface of the base material of nickel foam 0.5 Mn 2 O 4 Powder and then with anhydrous ethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com