Resin-based composite material with low dielectric loss, and preparation method and application thereof

A composite material and resin-based technology, which is applied in the field of low dielectric loss resin-based composite materials and its preparation, can solve the problem of high dielectric loss, and achieve the effects of easy processing and molding, recycling and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a low dielectric loss resin-based composite material according to an embodiment of the present invention, the specific steps include:

[0045] (1) Prepare the isocyanate-terminated prepolymer of nitrogen-containing coordinated cyclic borate, including:

[0046] Using aryl boronic acid compounds and nitrogen-containing ortho-hydroxy compounds with active hydrogen at the end group to react at room temperature, and then obtaining nitrogen-coordinated cyclic borate compounds containing active hydrogen after vacuum distillation and extraction;

[0047] A nitrogen-coordinated cyclic borate compound containing active hydrogen is reacted with an isocyanate compound to obtain a nitrogen-coordinated cyclic borate-terminated isocyanate prepolymer.

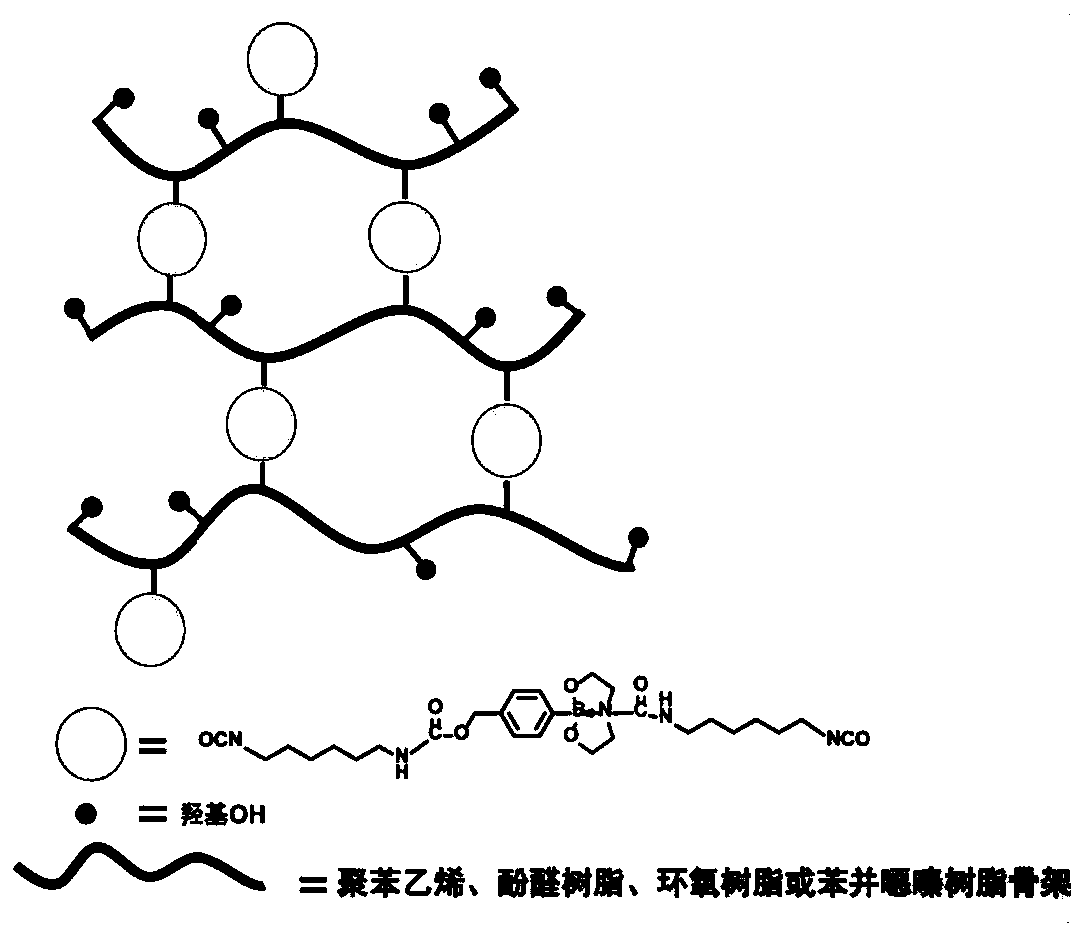

[0048] (2) The terminal isocyanate prepolymer of the nitrogen-containing coordination cyclic borate prepared in step (1) is used for crosslinking polystyrene, phenolic resin, epoxy resin or benzoxazine resin cont...

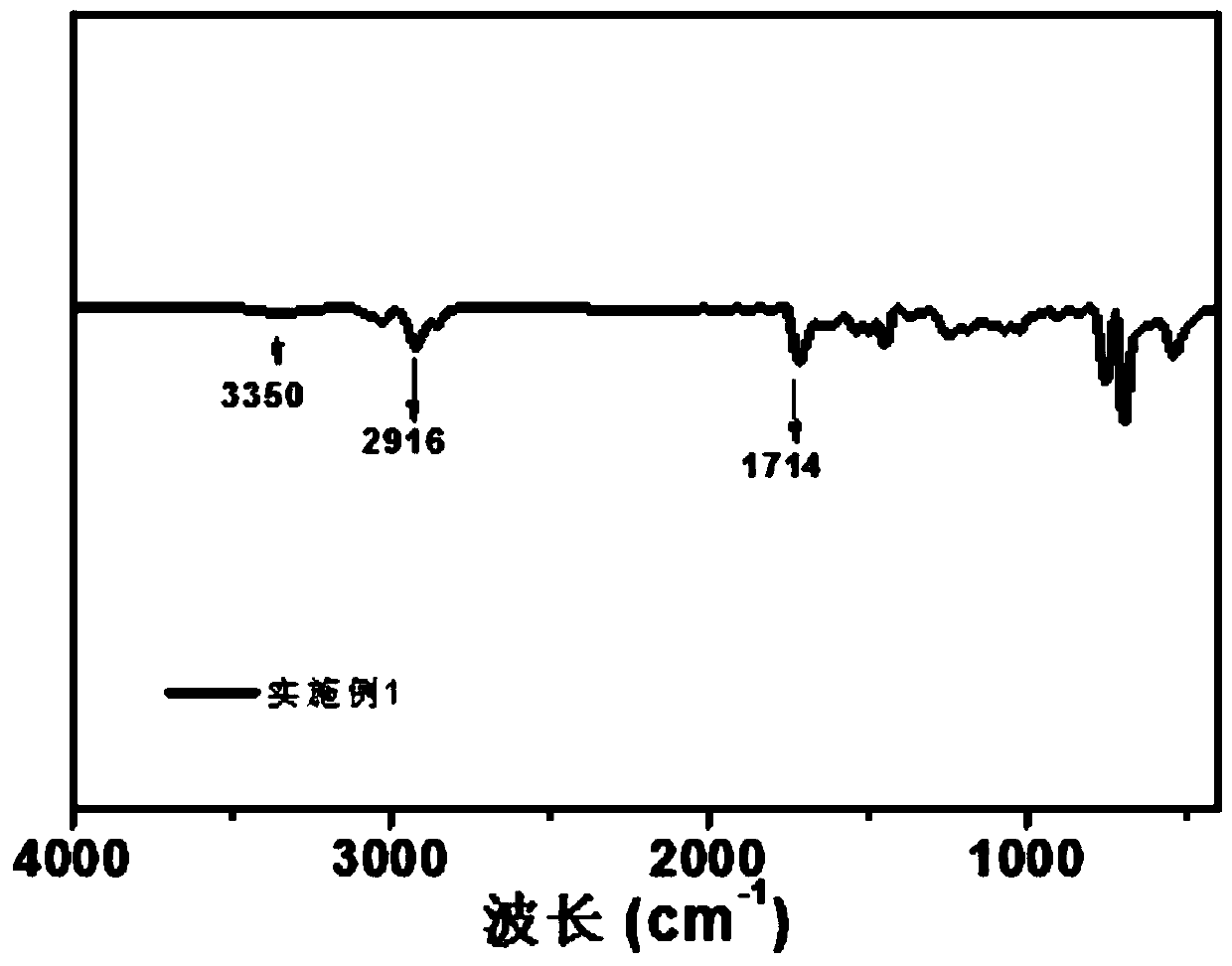

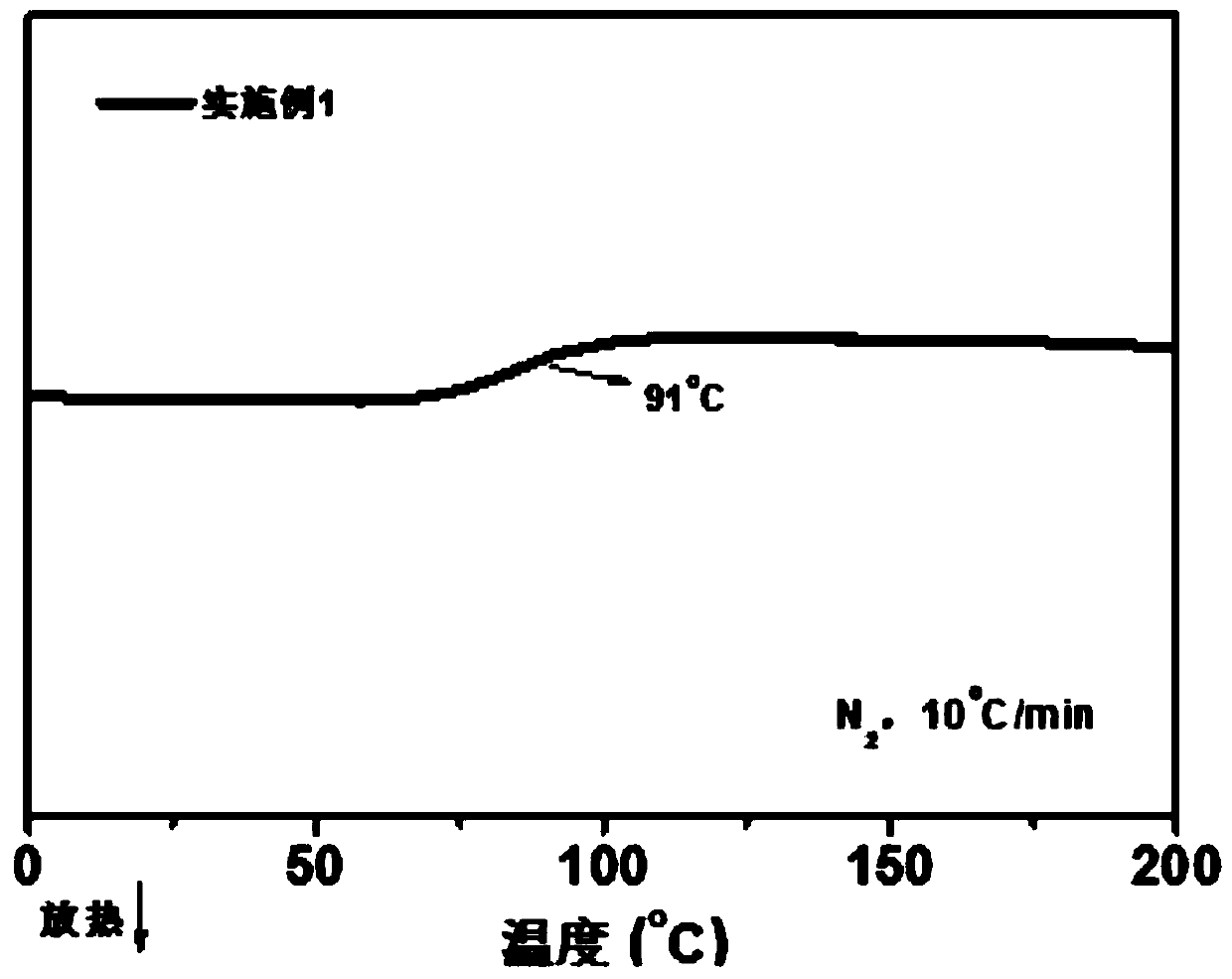

Embodiment 1

[0072] A method for preparing a low dielectric loss resin-based composite material according to an embodiment of the present invention, the specific steps include:

[0073] (1) Preparation of NCBU prepolymer: use arylboronic acid and triethanolamine (molar ratio is 1:1) to react at room temperature for 8h, and then obtain the active hydrogen (located at the end of the amino group and Hydrogen on the hydroxyl) nitrogen-coordinated cyclic borate compound;

[0074] Secondly, according to the molar ratio of the isocyanate group in the isocyanate compound to the amino group and the hydroxyl group in the nitrogen-coordinated cyclic borate compound is 1.5:1, weigh the measured nitrogen-coordinated cyclic borate compound and dissolve it in In anhydrous DMF, heat and stir at 90°C for 1 hour until completely dissolved; weigh a certain amount of diphenylmethane diisocyanate into a three-necked flask filled with anhydrous DMF, pass through nitrogen, and place in an oil bath at 50°C Heat ...

Embodiment 2

[0079] A method for preparing a low dielectric loss resin-based composite material according to an embodiment of the present invention, the specific steps include:

[0080] (1) Preparation of NCBU prepolymer: 4,4'-biphenyl diboronic acid and diethanolamine (1:1 molar ratio) were used to react at room temperature for 8 hours, and then obtained by vacuum distillation and extraction containing active hydrogen (Hydrogen on the amino group and hydroxyl at the terminal) nitrogen-coordinated cyclic borate compound; secondly, according to the isocyanate group in the isocyanate compound and the amino group and hydroxyl group in the nitrogen-coordinated cyclic borate compound The molar ratio is 1.2:1. Weigh and measure the nitrogen-coordinated cyclic borate ester compound and dissolve it in anhydrous DMF, heat and stir at 90°C for 1h until completely dissolved; weigh a certain amount of isophorone di Add isocyanate into a three-necked flask filled with anhydrous DMF, blow nitrogen into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com