A grinding wheel wear repairable device

A grinding wheel and compound cavity technology, which is applied in the direction of grinding drive device, abrasive surface adjustment device, grinding/polishing equipment, etc., can solve problems such as the influence of quality accuracy, and achieve the effect of efficient dressing, improving utilization rate and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

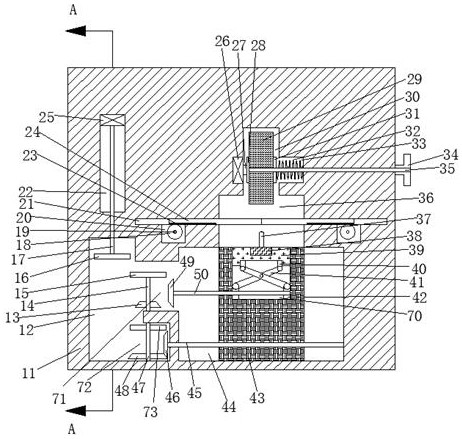

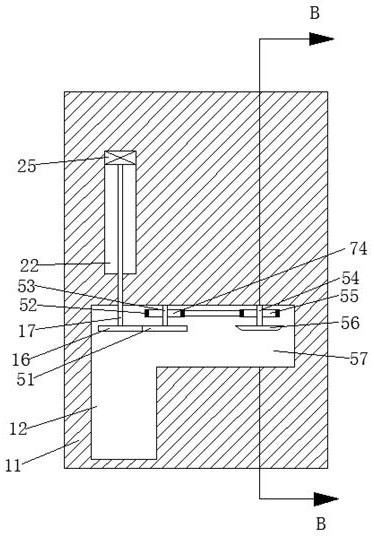

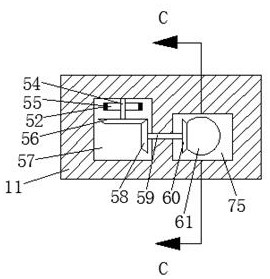

[0018] Bonded below Figure 1 - Figure 5 The present invention will be described in detail, which is convenient, and now, the orientation of the following statement is as follows: The upper and lower directions of the upper and lower directions said below figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0019] The present invention relates to a grinding wheel wear repairing device, mainly applied to the trim to the wear grinding wheel, and will further explain the present invention in connection with the drawings of the present invention:

[0020] A grinding wheel wear removable device according to the present invention includes an apparatus main body 11, and the inner lower end of the apparatus main body 11 is provided with a left and right slide cavity 44, and the left and right slide cavity 44 is rotatable between the two walls. The rod 45, the large threaded rod 45 outer surface thread is connected to the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com