Bidirectional borehole trimmer for well drilling

A dresser and wellbore technology, which is applied in the direction of wellbore/well components, earthwork drilling, etc., can solve the problems of low drilling efficiency, stuck pipe, and poor borehole quality, so as to save construction costs, avoid stuck pipe, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

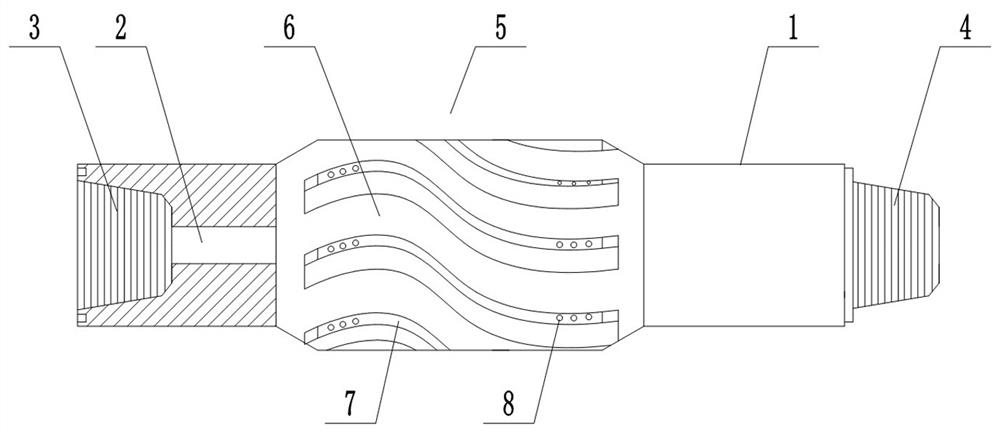

[0012] Such as figure 1 As shown, the present invention provides a two-way wellbore trimmer for drilling, which includes a body 1, a channel 2 is opened inside the body 1 along its axial direction, and an internal thread 3 for screwing with a drill pipe is provided at one end of the body 1 , the other end of the body 1 is provided with an external thread 4 for screwing with the drill pipe, the middle part of the body 1 is a working section 5, and the surface of the working section 5 is provided with a plurality of helical grooves 6 along the circumference, and the helical grooves The ribs 7 on both sides of the 6 are provided with cutting teeth 8, and the cutting teeth 8 are distributed at both ends of the outer surface of the ribs 7; the material of the cutting teeth 8 is a high wear-resistant alloy.

[0013] The number and arrangement of the cutting teeth 8 are not limited.

[0014] The specific working principle of the present invention: the present invention is applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com