A high-precision balanced sapphire double-sided grinding machine

A double-sided grinding and balancing technology, applied in the direction of grinding machine tools, grinding devices, grinding machine parts, etc., can solve the problems that it is difficult to ensure the consistency of precision and low efficiency on the bottom and bottom of the disk surface, and achieve efficient and fast dressing and balancing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

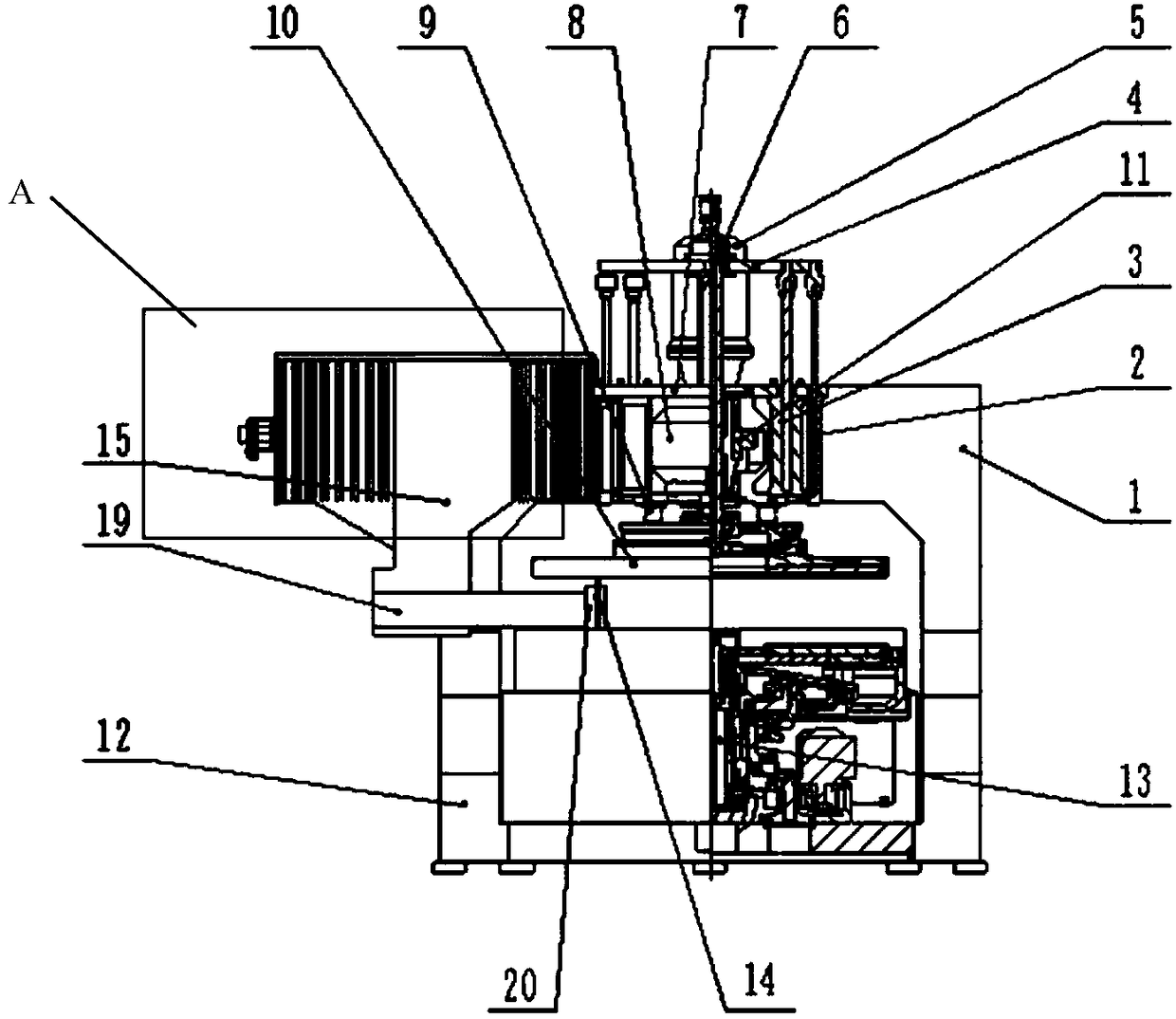

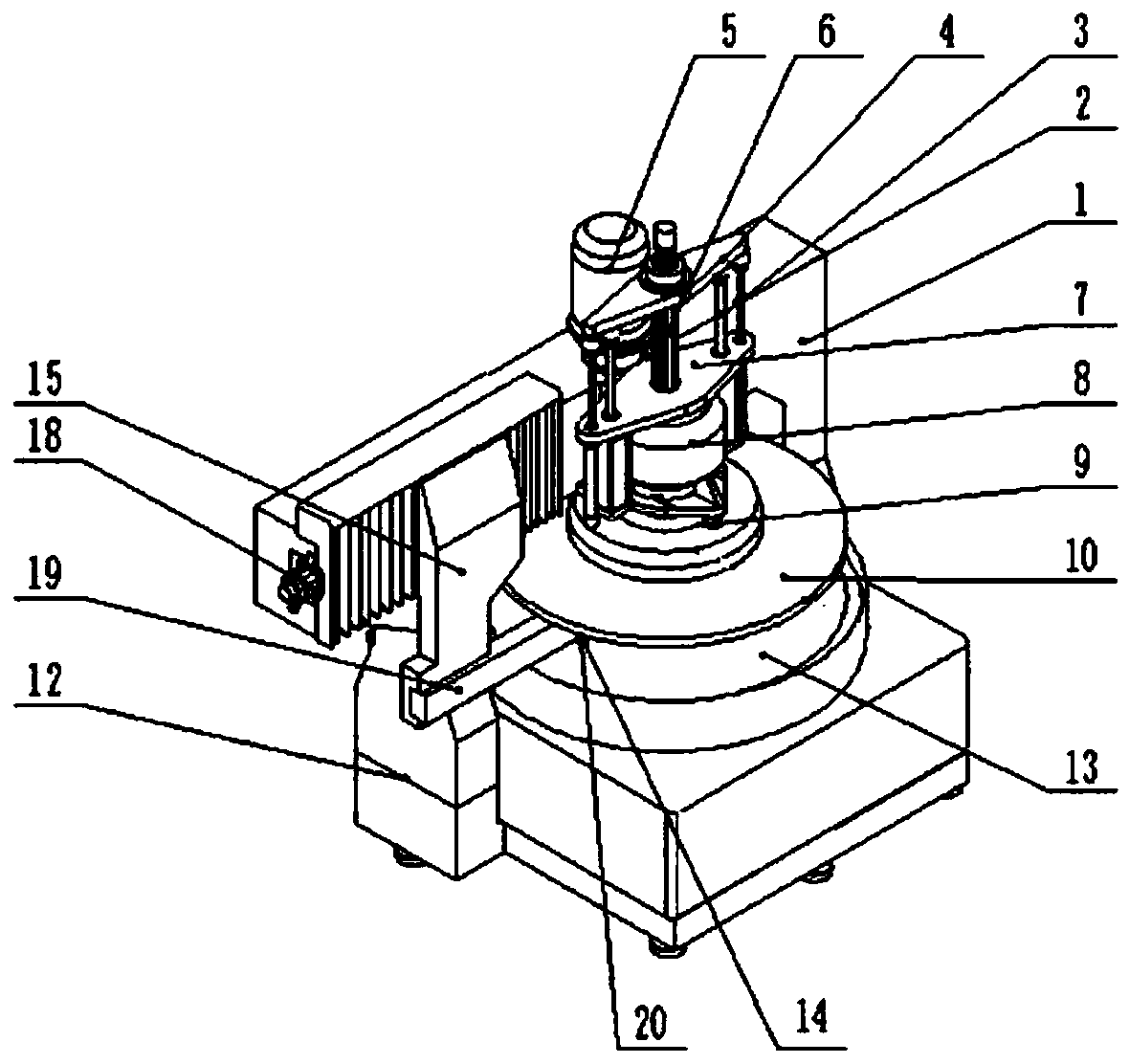

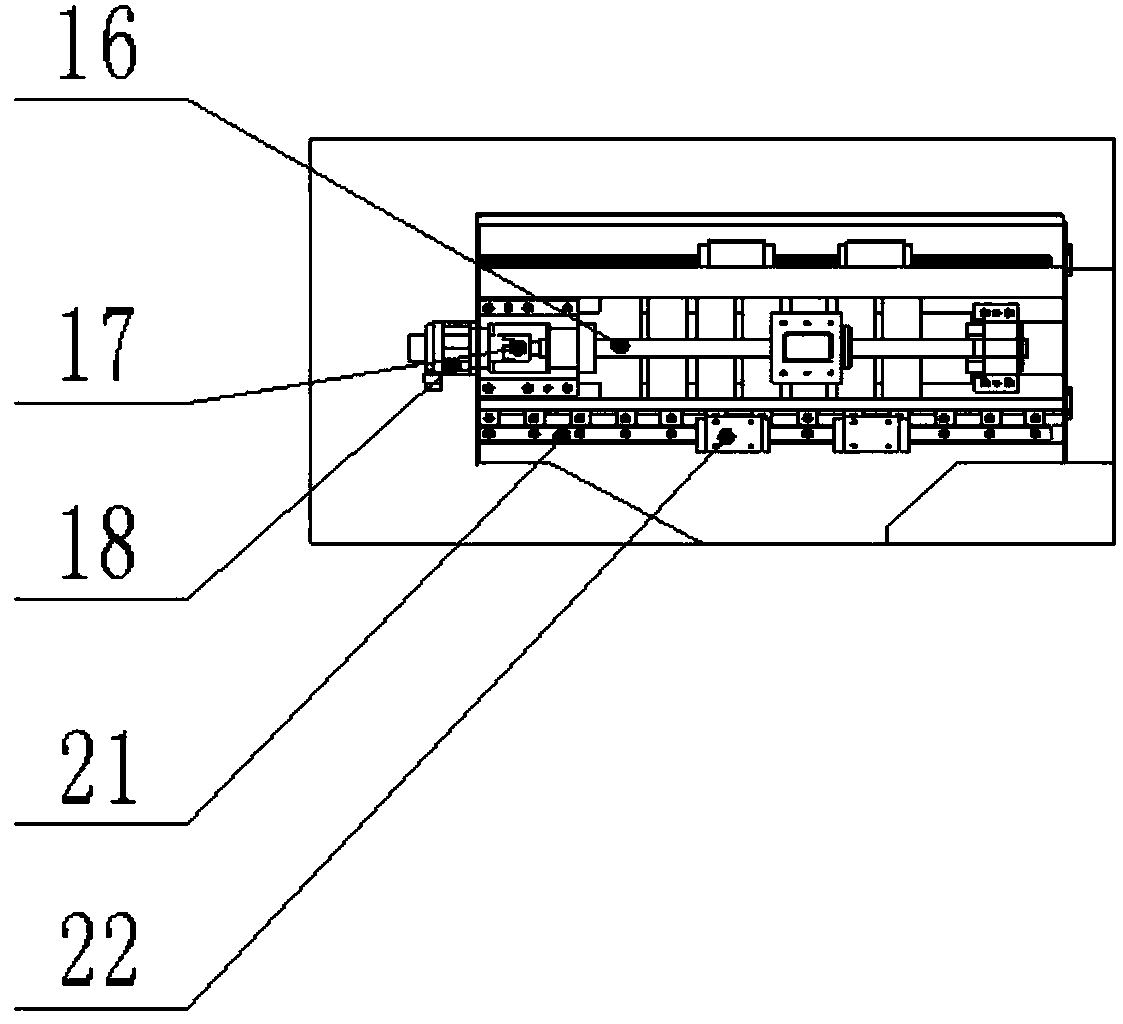

[0012] Such as figure 1 , figure 2 , image 3 The high-precision balanced sapphire double-sided grinding machine shown includes gantry column 1, counterweight hydraulic cylinder 2, air cylinder 3, upper connecting plate 4, planetary gear reducer 5, spline shaft 6, lower connecting plate 7, and Cover 8, level adjustment seat assembly 9, upper disk system 10, gear 11, chassis 12, lower disk system 13, cutter 14, saddle 15, screw rod 16, coupling 17, servo motor 18, cutter bar 19, Tool chuck 20, linear slide rail 21, slider 22. The chassis 1 is placed on the ground, and its level is guaranteed by the anchor nuts arranged on its bottom surface. The gantry column 4 is fixedly installed on the chassis, and the lower plate system 13 is installed on the chassis and is located between the two columns of the gantry column. The upper plate system 10 is located in the middle section of the beam on the top of the gantry column. The upper plate system 10 and the lower plate system 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com