Dressing unit and numerical control processing device

A technology for dressing wheels and workpieces, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low dressing efficiency of grinding wheels, achieve the effects of improving dressing efficiency, increasing service life, and preventing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The following description of the preferred embodiments is merely exemplary in nature and is not intended to limit the invention.

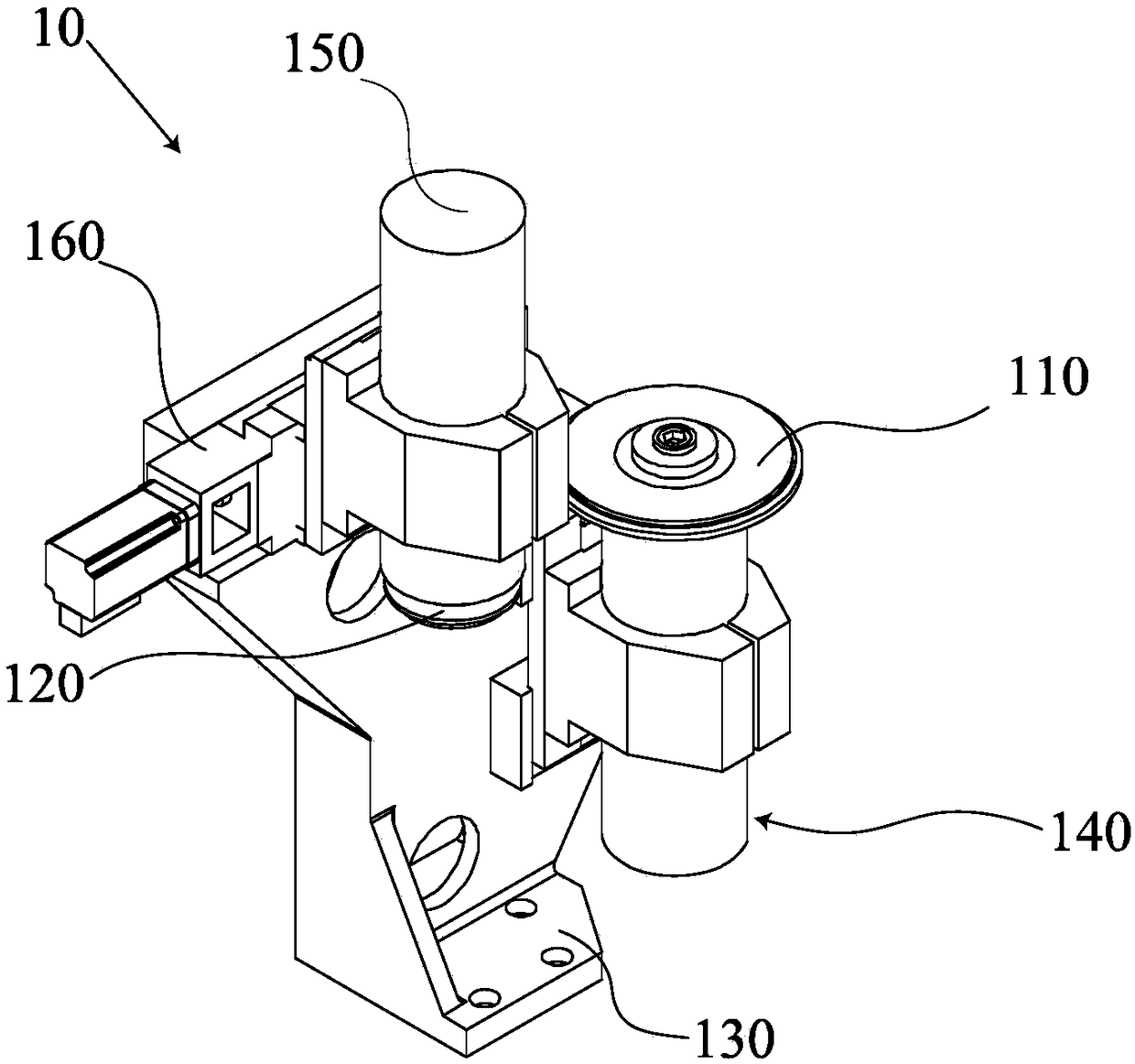

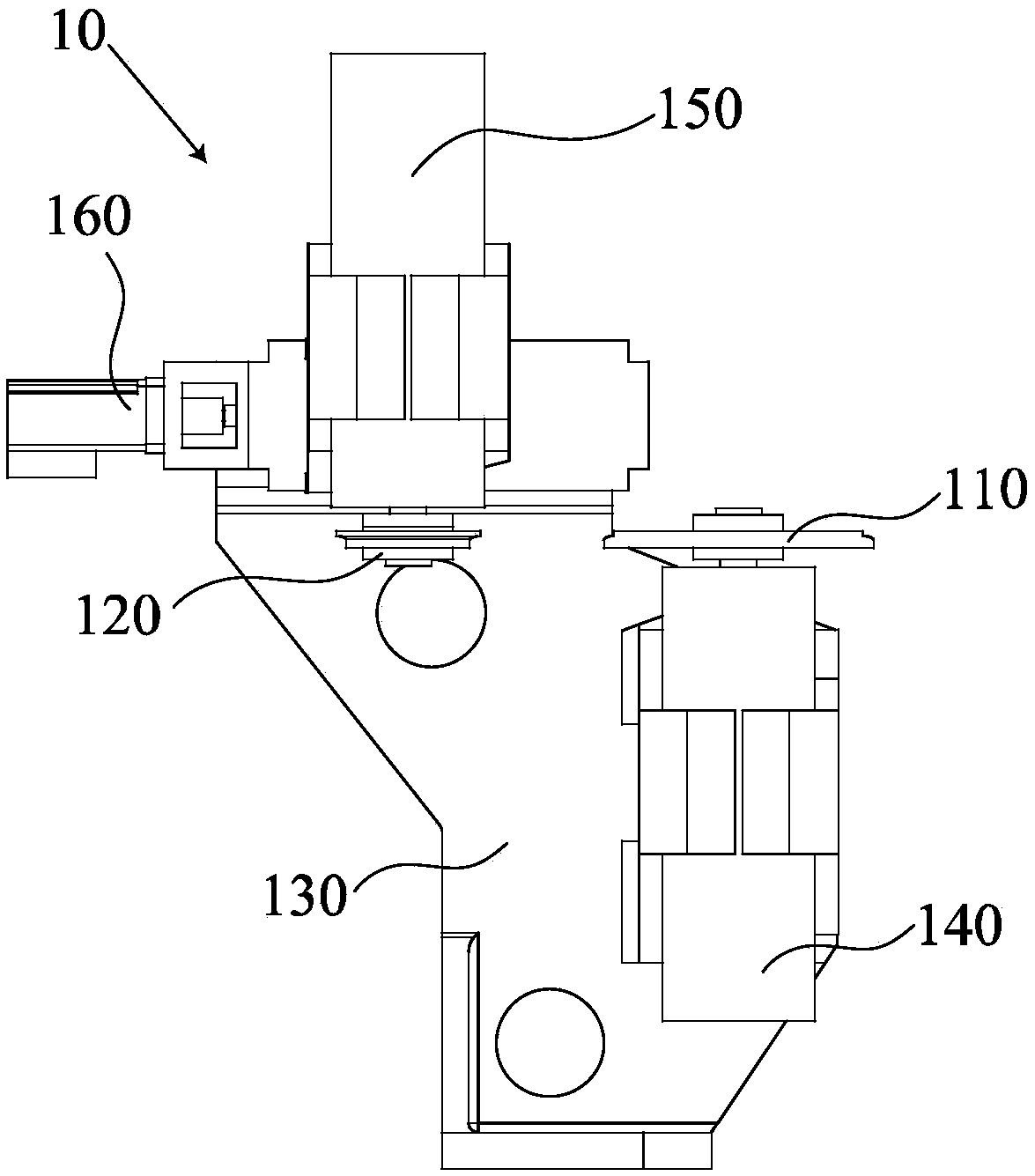

[0053] The following will refer to Figures 1 to 13A -13C describes in detail the trimming unit 10 and the numerical control machining apparatus 1 including the trimming unit 10 according to the embodiment of the present application.

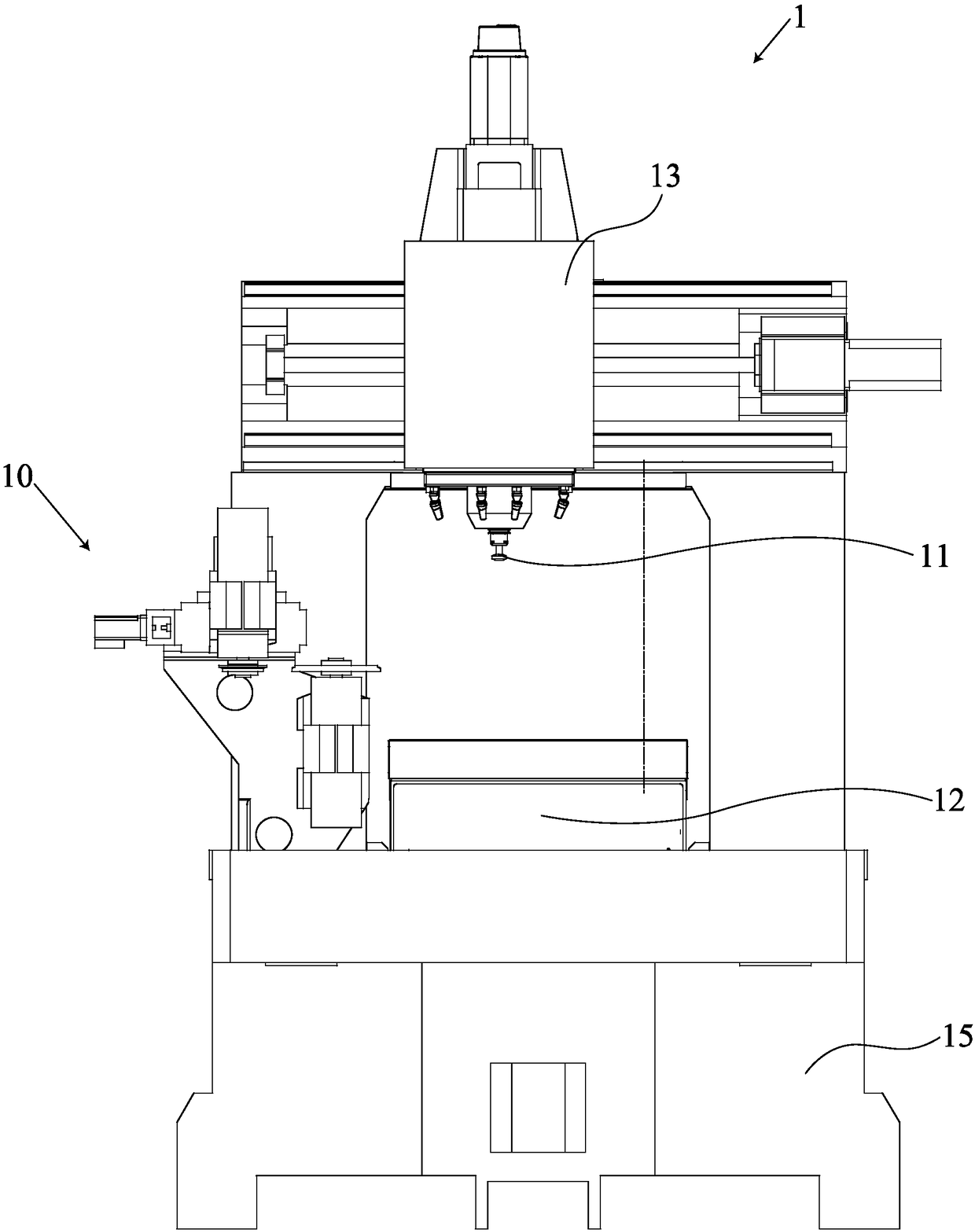

[0054] Such as figure 1 As shown, the numerical control processing equipment 1 may include a grinding wheel 11, a workpiece table 12 and a base 15, wherein the numerical control processing equipment 1 can digitally control the operation of each component to achieve efficient, precise, integrated, automatic, safe, stable processing, etc. Beneficial technical effect. The base 15 has a certain weight and can sit on the floor of the production workshop to provide good stability for the numerical control machining equipment 1 . The workpiece table 12 may be arranged on the base 15 and fixed or movable relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com