A kind of high performance rare earth tool steel and preparation method thereof

A tool steel and high-performance technology, applied in the field of high-performance rare earth tool steel and its preparation, can solve the problem of high production cost, and achieve the effects of improving strength, high tropism, and strengthening grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

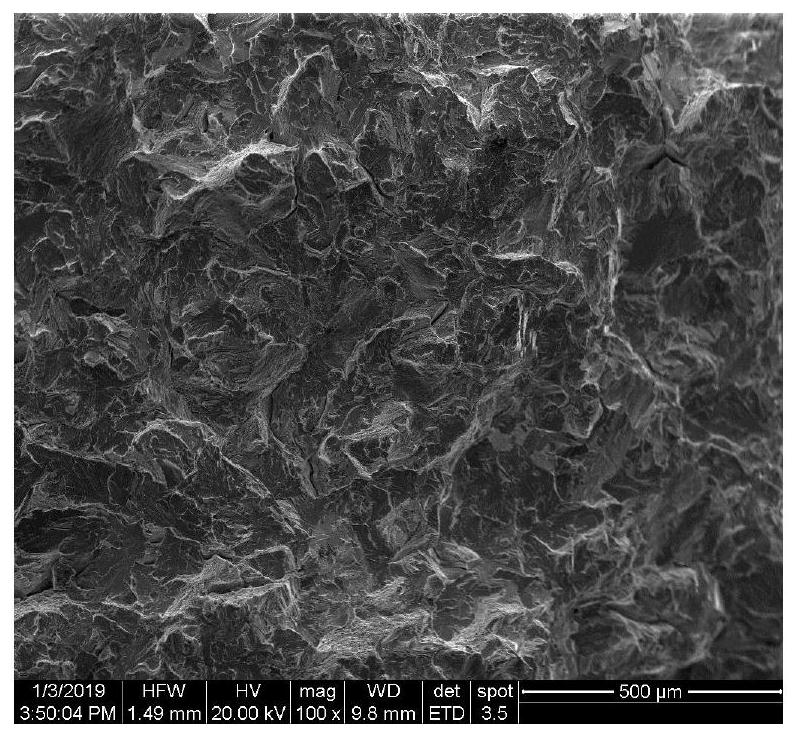

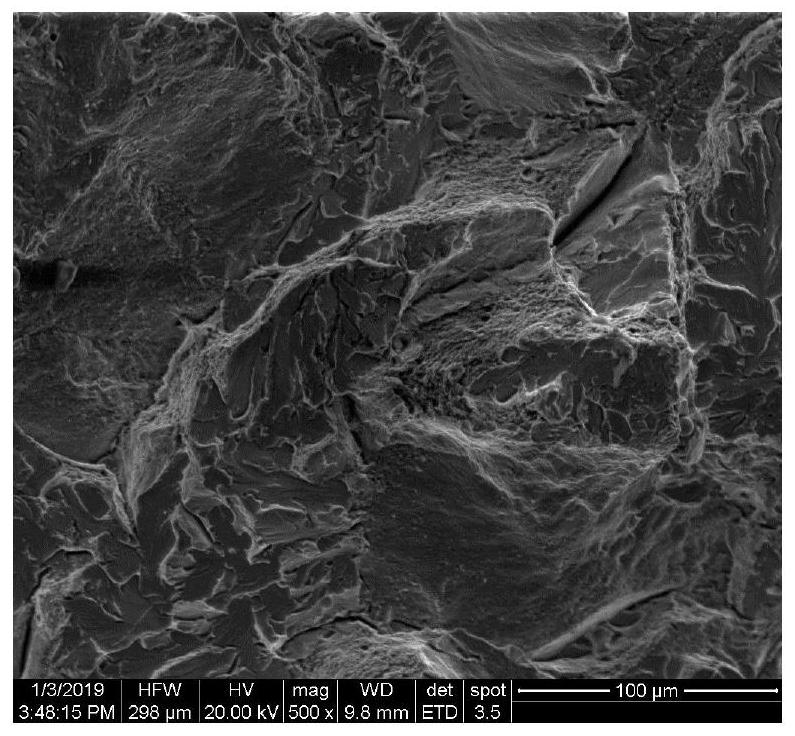

Image

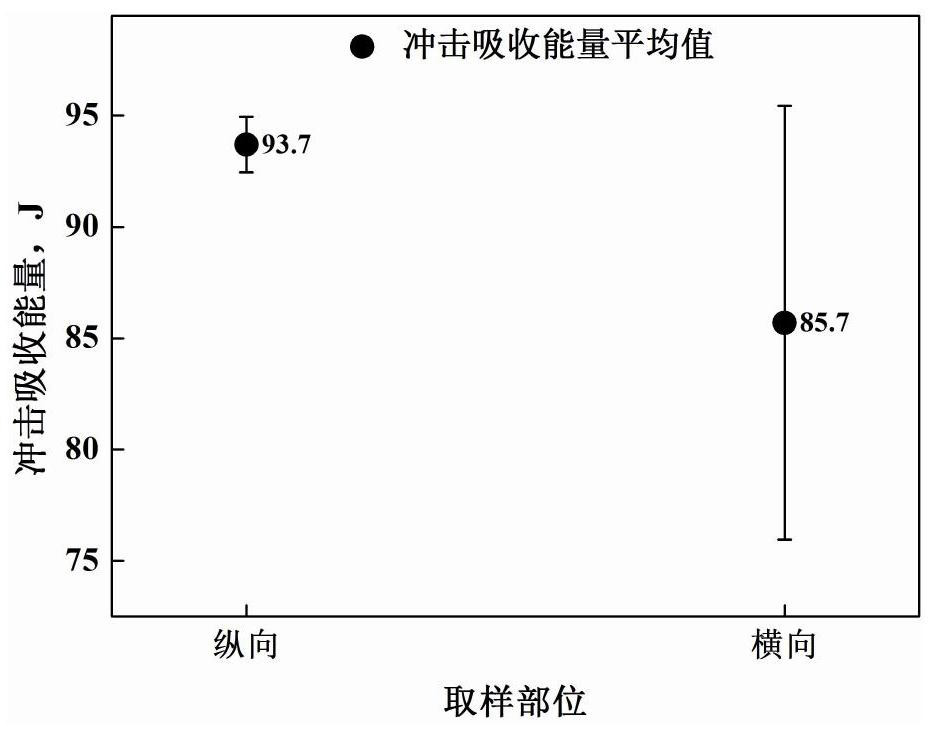

Examples

Embodiment 1

[0045] Embodiment 1: Preparation of high performance rare earth tool steel

[0046] Its chemical composition and weight percentage are: carbon 0.23%, silicon 0.25%, manganese 0.31%, sulfur 0.002%, phosphorus 0.015%, chromium 1.18%, nickel 2.99%, molybdenum 0.418%, vanadium 0.015%, lanthanum cerium alloy 0.012%, The balance is iron.

[0047](1) Smelting, mixing pure iron, metallic chromium, ferrochromium nitride, electrolytic nickel, ferrovanadium, ferrosilicon, and ferromanganese according to the chemical composition and weight percentage of high-performance rare earth tool steel and putting them into an intermediate frequency induction furnace for melting Molten steel is formed at a temperature of 1590-1650°C for 1 hour. Through the analysis of the spectral composition in front of the furnace, the missing alloy charge is added until the composition requirements of the molten steel are met; (2) Refining. The chemical composition and weight percentage of the lanthanum-cerium a...

Embodiment 2

[0048] Embodiment 2: Preparation of high performance rare earth tool steel

[0049] Its chemical composition and weight percentage are: carbon 0.20%, silicon 0.22%, manganese 0.30%, sulfur 0.015%, phosphorus 0.013%, chromium 1.20%, nickel 3.10%, molybdenum 0.420%, vanadium 0.020%, lanthanum cerium alloy 0.015%, The balance is iron.

[0050] The preparation method includes the following steps: (1) smelting, mixing pure iron, metal chromium, ferrochrome nitride, electrolytic nickel, ferrovanadium, ferrosilicon and ferromanganese according to the chemical composition and weight percentage of high-performance rare earth tool steel Put it into an intermediate frequency induction furnace and melt it into molten steel at a temperature of 1590-1650°C for 1 hour. Through the analysis of the spectral composition before the furnace, add the missing alloy charge until the molten steel composition requirements are met; (2) Refining, the molten steel is transferred to the refining furnace ...

Embodiment 3

[0051] Embodiment 3: Preparation of high performance rare earth tool steel

[0052] Its chemical composition and weight percentage are: carbon 0.25%, silicon 0.28%, manganese 0.33%, sulfur 0.009%, phosphorus 0.010%, chromium 1.10%, nickel 2.90%, molybdenum 0.410%, vanadium 0.010%, lanthanum cerium alloy 0.010%, The balance is iron.

[0053] The preparation method includes the following steps: (1) smelting, mixing pure iron, metal chromium, ferrochrome nitride, electrolytic nickel, ferrovanadium, ferrosilicon and ferromanganese according to the chemical composition and weight percentage of high-performance rare earth tool steel Put it into an intermediate frequency induction furnace and melt it into molten steel at a temperature of 1590-1650°C for 1 hour. Through the analysis of the spectral composition before the furnace, add the missing alloy charge until the molten steel composition requirements are met; (2) Refining, the molten steel is transferred to the refining furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com