Nanometer flame-retardant soundproof adiabatic material used for aerospace

A nano-flame-retardant and heat-insulating material technology, applied in the direction of coating, layered products, metal layered products, etc., can solve the problems of poor shock absorption, poor heat insulation performance, and low horizontal and vertical tensile strength of thermal insulation materials, and achieve Good heat insulation effect, reduced gas convection, excellent heat insulation and sound absorption and noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

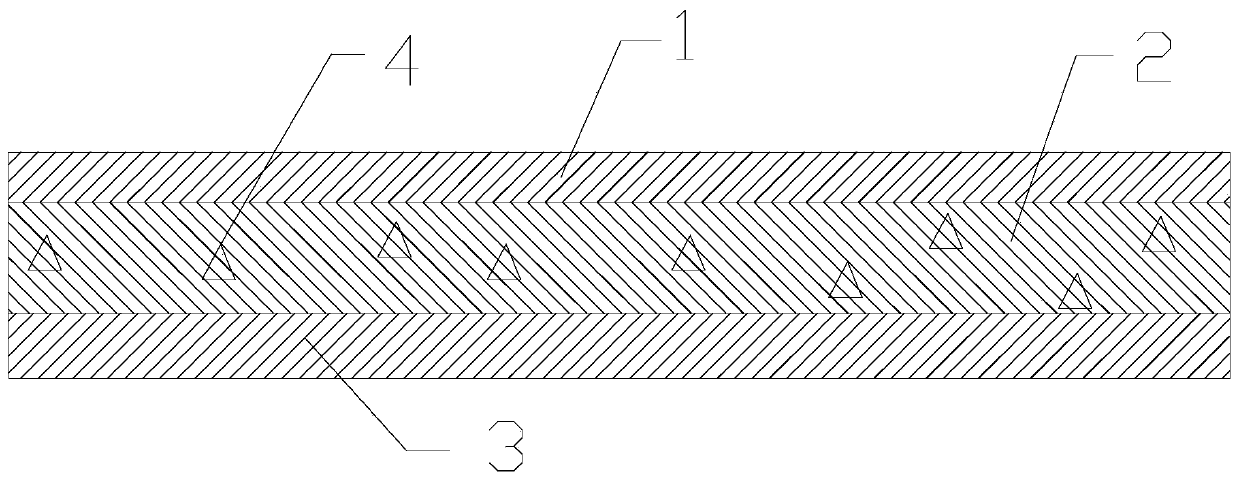

Image

Examples

Embodiment 1

[0024] As a specific embodiment of the present invention, the LLDPE layer thickness is 50 μm, the aluminum foil is 0.1 micron, the PET layer is 12 micron, the aluminum foil is 0.1 micron, the PET layer is 12 micron, the aluminum foil is 0.1 micron, and the PET layer is 12 micron. Materials, the middle layer is made of glass fiber with a diameter of 10-75 microns, and the surface layer is mirror-faced aluminum foil coated with nano-silica. After compounding, vacuum treatment is performed to obtain a nano-flame-retardant sound-insulating and heat-insulating material.

[0025] Through the neutral salt spray test on the sample, after 200 hours, the damage area is less than 0.1%, and the surface reflectance test is more than 86%. At the same time, the ultraviolet radiation exposure test is also carried out. After 200 hours, the product monogram level reaches level 4.

[0026] At the same time, the average transverse tensile strength of the measured sample was 1.5×10 3 KPa, the aver...

Embodiment 2

[0028] The aluminum-plastic composite material is sequentially selected to set the thickness of the LLDPE layer to 90 μm, the aluminum foil to 0.5 μm, the PET layer to 8 μm, the aluminum foil to 0.1 μm, the PET layer to 10 μm, the aluminum foil to 0.15 μm, and the PET layer to be 20 μm. After the preparation of the aluminum-plastic composite material, the middle layer Glass fiber is selected, with a diameter of 10-75 microns, and the surface layer is mirror-surface aluminum foil coated with nano-silica. After compounding, vacuum treatment is performed to obtain nano-flame-retardant, sound-insulating and heat-insulating materials.

[0029] Through the neutral salt spray test on the sample, after 200 hours, the damage area is less than 0.1%, and the surface reflectance test is more than 88%. At the same time, the ultraviolet radiation exposure test is also carried out. After 200 hours, the product monogram grade reaches level 4.

[0030] At the same time, the average transverse t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com