Phytosterol ester microcapsule and preparation method and application thereof

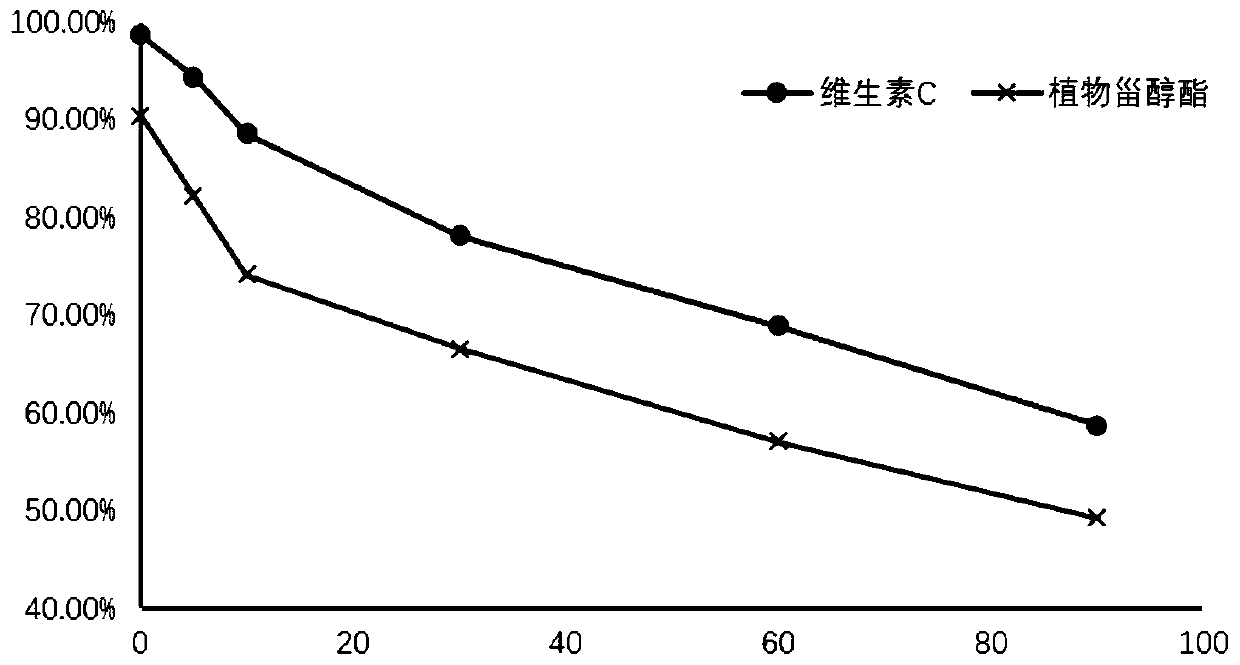

The technology of phytosterol ester and phytosterol is applied in the field of phytosterol ester microcapsule and its preparation, which can solve the problems of easy oxidative deterioration of core material, uneven particle size, short drying process, etc., and achieves good emulsification effect and improved water solubility. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) be 2% vitamin C aqueous solution as water phase with mass fraction, phytosterol ester is as oil phase, 50g water phase is joined in the 60g oil phase phytosterol ester, then add 2g emulsifier lecithin and phytosterol ( The mass ratio of lecithin and phytosterol is 1:1), and dispersed at 12000r / min for 5min to obtain a W / O emulsion;

[0041] (2) Mixing gum arabic and pectin in a mass ratio of 1:4 to obtain a mixed colloid; then dissolving the mixed colloid in water to obtain a mixed colloid solution, wherein the mass fraction of the mixed colloid is 1.5%;

[0042](3) under stirring condition, the W / O emulsion that 44g step (1) makes is slowly added in the 38g mixed colloid solution, mixes, and then adding 10g massfraction is 1.5% chitosan acetic acid solution (chitosan Sugar molecular weight is 150,000), mix evenly, obtain mixed system;

[0043] (4) adjusting the pH of the reaction system in step (3) to 3.5, stirring and reacting at 30°C for 8h, then standing at 4°C...

Embodiment 2

[0046] (1) be the vitamin C aqueous solution of 0.5% as water phase with mass fraction, phytosterol ester is as oil phase, 60g water phase is joined in the 60g oil phase phytosterol ester, then add 3g emulsifier lecithin and phytosterol ( The mass ratio of lecithin and phytosterol is 2:3), dispersed at 10000r / min for 10min to obtain W / O emulsion;

[0047] (2) Mixing gum arabic and pectin in a mass ratio of 1:3 to obtain a mixed colloid; then dissolving the mixed colloid in water to obtain a mixed colloid solution, wherein the mass fraction of the mixed colloid is 1%;

[0048] (3) under stirring condition, slowly join in the W / O emulsion that 45g step (1) makes in the 35g mixed colloid solution, mix well, then add 10g massfraction again and be 1% chitosan acetic acid solution (chitosan Sugar molecular weight is 150,000), mix evenly, obtain mixed system;

[0049] (4) adjusting the pH of the reaction system in step (3) to 4.0, stirring and reacting at 25°C for 12h, then standing...

Embodiment 3

[0052] (1) be the vitamin C aqueous solution of 5% as water phase with mass fraction, phytosterol ester is as oil phase, 40g water phase is joined in the 60g oil phase phytosterol ester, then add 0.5g emulsifier lecithin and phytosterol (The mass ratio of lecithin and phytosterol is 4:3), dispersed at 11000r / min for 4min to obtain W / O emulsion;

[0053] (2) Mixing gum arabic and pectin in a mass ratio of 1:5 to obtain a mixed colloid; then dissolving the mixed colloid in water to obtain a mixed colloid solution, wherein the mass fraction of the mixed colloid is 2%;

[0054] (3) under stirring condition, slowly join the W / O emulsion that 52.5g step (1) makes in the 32g mixed colloid solution, mix well, then add 10g massfraction again and be the chitosan acetic acid solution of 2% (shell The molecular weight of the polysaccharide is 150,000), mixed evenly to obtain a mixed system;

[0055] (4) adjusting the pH of the reaction system in step (3) to 3.8, stirring and reacting at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com